Zero-formaldehyde antibacterial robe lining cloth

A zero-formaldehyde, interlining technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve the problems of carbon rod uniform diameter adsorption performance, etc., to achieve the effect of increasing added value, improving comfort and health value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

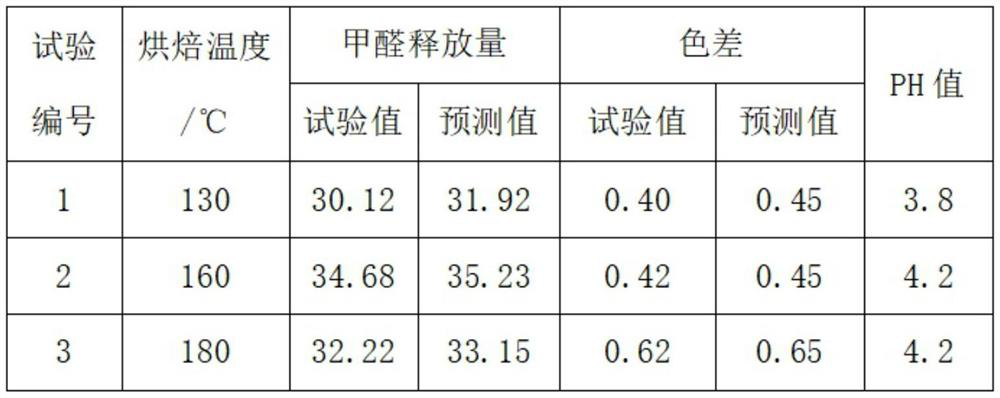

Embodiment 1

[0020] Includes raw materials of the following mass parts: base fabric, environmentally friendly antibacterial agent, zerohyset resin, anti-UV auxiliary, anti-infrared auxiliaries, LDPE masterbatch, antibacterial parental, anti-UV parent, anti-infrared masterbatch and functional resin.

[0021] Including the following processing steps,

[0022] Step 1: The base fabric is immersed by the antibacterial antibacterial agent, there is formaldehyde resin, antibacterial agent, anti-UV auxiliaries, anti-infrared auxiliary treatment, and antibacterial effect reaches the company's internal control standard and then performs the following step;

[0023] Step 2: Press the surface of the antibacterial resin in the abutment of the antibacterial resin by casting the LDPE parent, antibacterial parent, anti-UV masterbatch, anti-infrared parent, and anti-infrared parent particles;

[0024] Step 3: Cooling molding is cut to a fixed width.

[0025] It mainly includes woven woven woven cotton cloth, p...

Embodiment 2

[0033] Includes raw materials of the following mass parts: base fabric, environmentally friendly antibacterial agent, zerohyset resin, anti-UV auxiliary, anti-infrared auxiliaries, LDPE masterbatch, antibacterial parental, anti-UV parent, anti-infrared masterbatch and functional resin.

[0034] Including the following processing steps,

[0035] Step 1: The base fabric is immersed by the antibacterial antibacterial agent, there is formaldehyde resin, antibacterial agent, anti-UV auxiliaries, anti-infrared auxiliary treatment, and antibacterial effect reaches the company's internal control standard and then performs the following step;

[0036] Step 2: Press the surface of the antibacterial resin in the abutment of the antibacterial resin by casting the LDPE parent, antibacterial parent, anti-UV masterbatch, anti-infrared parent, and anti-infrared parent particles;

[0037] Step 3: Cooling molding is cut to a fixed width.

[0038] It mainly includes woven woven woven cotton cloth, p...

Embodiment 3

[0046] Includes raw materials of the following mass parts: base fabric, environmentally friendly antibacterial agent, zerohyset resin, anti-UV auxiliary, anti-infrared auxiliaries, LDPE masterbatch, antibacterial parental, anti-UV parent, anti-infrared masterbatch and functional resin.

[0047] Including the following processing steps,

[0048] Step 1: The base fabric is immersed by the antibacterial antibacterial agent, there is formaldehyde resin, antibacterial agent, anti-UV auxiliaries, anti-infrared auxiliary treatment, and antibacterial effect reaches the company's internal control standard and then performs the following step;

[0049] Step 2: Press the surface of the antibacterial resin in the abutment of the antibacterial resin by casting the LDPE parent, antibacterial parent, anti-UV masterbatch, anti-infrared parent, and anti-infrared parent particles;

[0050] Step 3: Cooling molding is cut to a fixed width.

[0051] It mainly includes woven woven woven cotton cloth, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com