Quenched and tempered steel plate with yield strength being 420 MPa grade for building structure and production method of quenched and tempered steel plate

A technology for yield strength and building structure, which is applied in the field of steel plates for quenched and tempered building structures, and can solve the problems that the yield strength is difficult to meet the standard requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

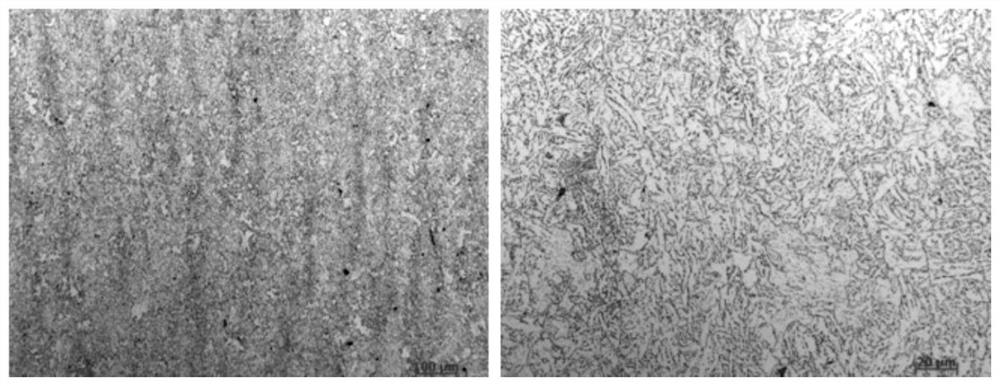

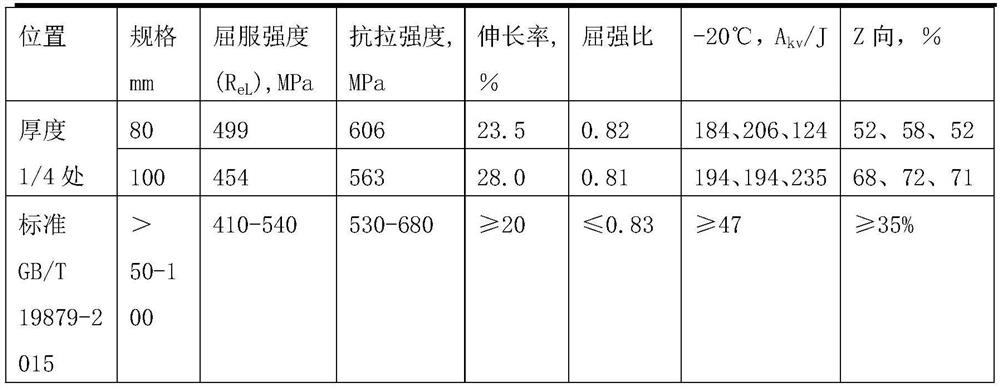

[0025] Example 1: Adopt Q420GJC / D thick 370mm continuous casting blank according to the smelting chemical composition of the design of the present invention to produce an example of rolling 80mm thick steel plate. The continuous casting slab is 370×2120×3605mm, and the rolled finished plate is 80×2437×L (length) mm. The billet is cold loaded into the heating furnace. The temperature of the preheating section of the heating furnace is ≤900°C, the temperature of the first stage of heating is 1000-1180°C, the temperature of the second stage of heating: 1210-1250°C, the temperature of the soaking section: 1190-1250°C; the total heating time≥ 400 minutes. Rough rolling is rolled for 5 passes. After warming, the starting rolling temperature of the finish rolling mill is ≤875°C. The finish rolling is rolled for 7 passes, and the final rolling temperature is ≤850°C. Stacking slow cooling; the quality inspection of the steel plate after tempering at 690°C, the physical and chemical pe...

example 2

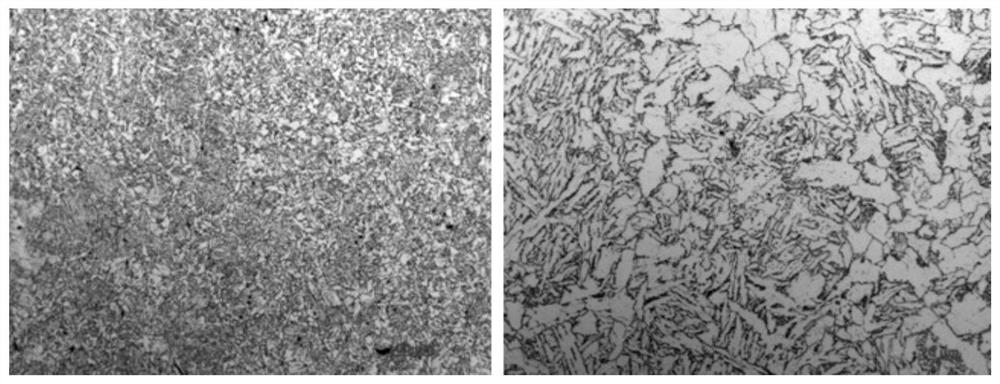

[0026] Example 2: Adopt Q420GJC / D thick 450mm continuous casting billet according to the smelting chemical composition of the design of the present invention, and produce an example of rolling 100mm thick steel plate. The continuous casting slab is 450×1920×4000mm, and the rolled finished plate is 100×2660×L (length) mm. The billet is cold loaded into the heating furnace. The temperature of the preheating section of the heating furnace is ≤900°C, the temperature of the first stage of heating is 1000-1180°C, the temperature of the second stage of heating: 1210-1250°C, the temperature of the soaking section: 1190-1250°C; the total heating time≥ 500 minutes. Rough rolling is rolled 8 times, after warming, the starting rolling temperature of the finishing mill is ≤870°C, the finishing rolling is rolled through 9 passes, and the final rolling temperature is ≤850°C; after rolling, it is directly water-cooled and quenched to 297°C before it is rolled off the production line Stacking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com