A preparation method of niobium-containing nano-bainite steel with good thermal stability

A technology for thermal stability of bainitic steel, applied in the field of iron and steel materials, can solve the problems of unreported thermal stability of nano-bainitic steel, difficulty in precise control, complicated production process, etc., to compensate for the reduction of dislocation density and easy The effect of simple operation and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The embodiment of the present invention provides a preparation method of niobium-containing nano-bainite steel with good thermal stability. The chemical composition and content of the bainite steel are: C 0.28%; Si 1.50%; Mn 1.5%; Cr 1.2% %; Al 1.97%; Mo0.80%; Ni 0.62%; Nb 0.018%; the rest is Fe and unavoidable impurities.

[0023] Its heat treatment method specifically comprises the following steps:

[0024] The nano-bainitic steel billet was homogenized at 1200°C for 24 hours under vacuum to reduce the segregation of alloying elements. After cooling to room temperature, take Cylindrical samples. The start temperature of martensitic transformation of the nano-bainite steel was determined to be 330°C with a Gleeble 3500 thermal simulator.

[0025] The nano-bainite steel was austenitized at 980°C for 0.5h; then cooled to 330°C at a rate of 20°C / s and held for 1h. Finally air cool to room temperature.

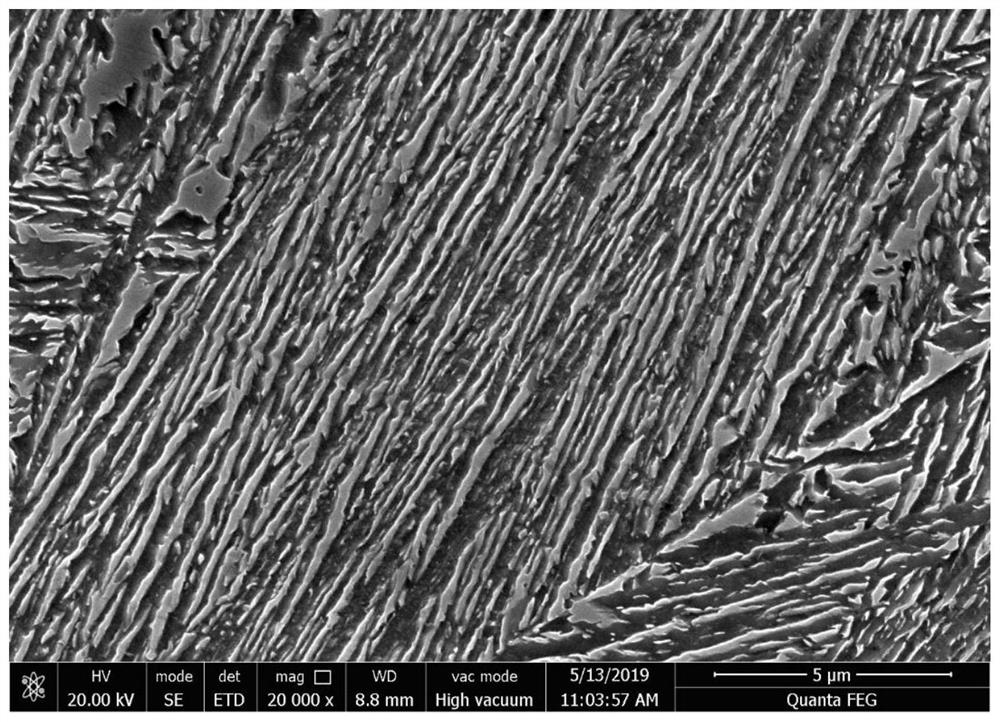

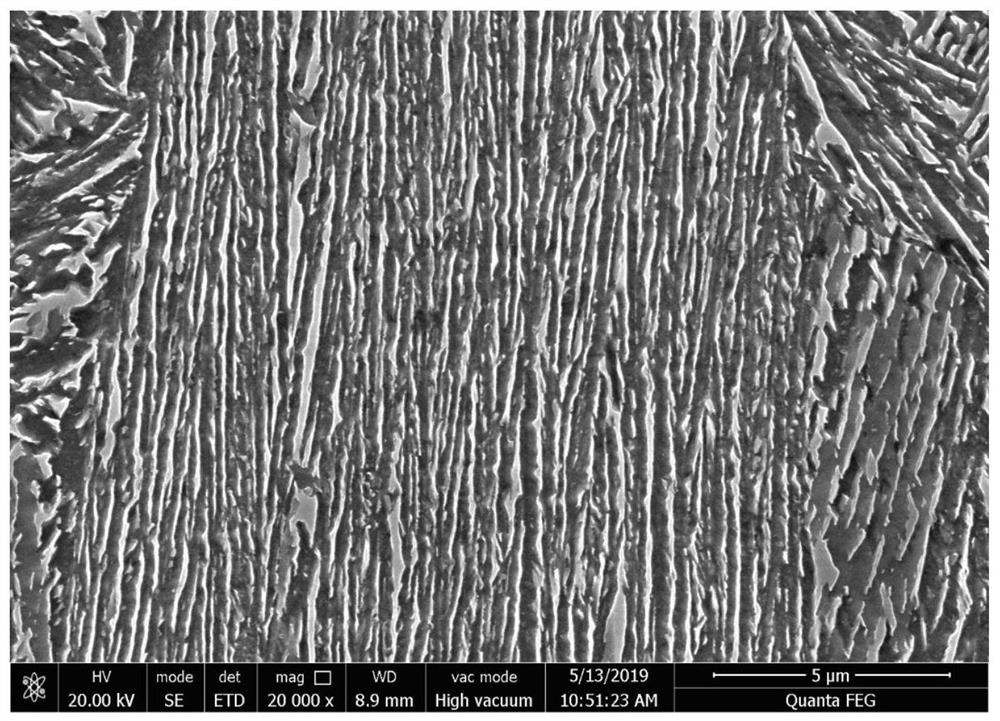

[0026] figure 1 and figure 2 The microstructures of niobium-...

Embodiment 2

[0030] The embodiment of the present invention provides a method for preparing niobium-containing nano-bainite steel with good thermal stability. The chemical composition and content of the bainite steel are: C 0.29%; Si 1.40%; Mn 1.50%; Cr 1.30 %; Al 1.6%; Mo0.89%; Ni 0.61%; Nb 0.019%; the rest is Fe and unavoidable impurities.

[0031] Its heat treatment method specifically comprises the following steps:

[0032] The nano-bainitic steel blank was homogenized at 1200°C for 24 hours under vacuum to reduce the segregation of alloying elements. After cooling to room temperature, take Cylindrical samples. Using Gleeble3500 thermal simulation testing machine, it was measured that the martensitic transformation initiation temperature of the nano-bainite steel was 332°C.

[0033] The nano-bainitic steel was austenitized at 1000°C for 0.5h; then cooled to 335°C at a rate of 20°C / s and kept at a temperature of 1h. Finally air cool to room temperature.

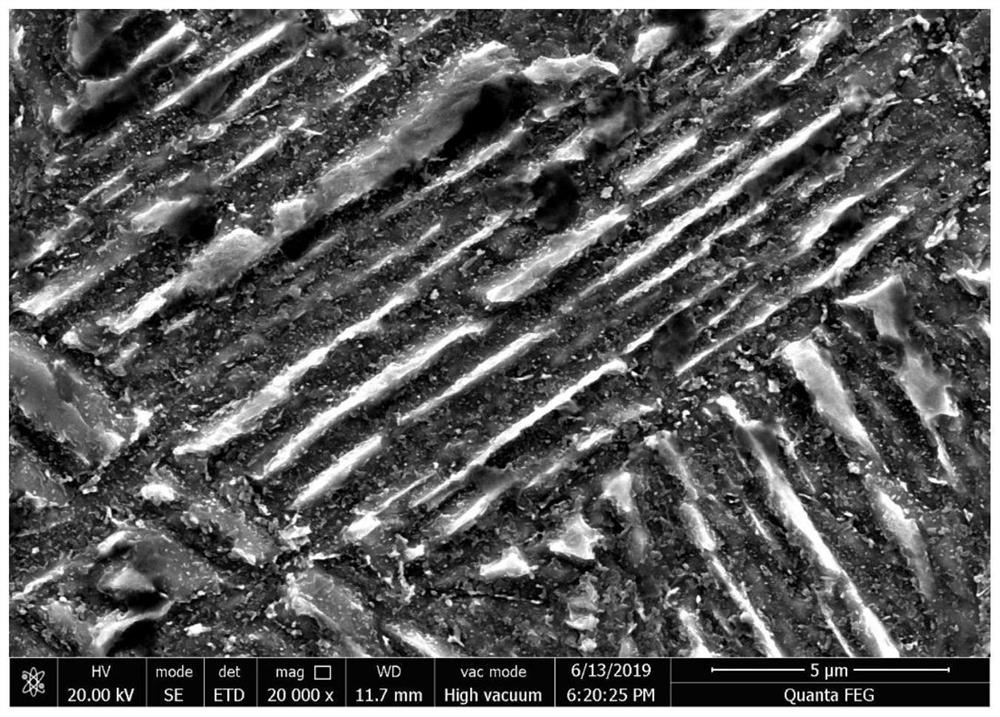

[0034] Figure 4 The micr...

Embodiment 3

[0038] The embodiment of the present invention provides a preparation method of niobium-containing nano-bainite steel with good thermal stability. The chemical composition and content of the nano-bainite steel are: C 0.32%; Si 1.40%; Mn 1.51%; Cr 1.18%; Al 1.16%; Mo 0.49%; B 0.003%; Ni 0.61%; Nb 0.019%; the rest is Fe and unavoidable impurities.

[0039] Its heat treatment method specifically comprises the following steps:

[0040] The nano-bainitic steel billet was homogenized at 1200°C for 24 hours under vacuum to reduce the segregation of alloying elements. After cooling to room temperature, take Cylindrical samples. Using a Gleeble 3500 thermal simulation testing machine, it was determined that the martensitic transformation initiation temperature of the nano-bainite steel was 328°C.

[0041] The nano-bainitic steel was austenitized at 1000°C for 0.5h; then rapidly cooled to 323°C at a rate of 30°C / s, and kept for 5s; then kept at 340°C for 1h; finally air-cooled to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com