Magnesium-doped calcium silicate crystal nucleus early strength agent with long-term stability and preparation method thereof

A calcium silicate and stability technology, applied in the field of magnesium-doped calcium silicate crystal nucleus early strength agent and preparation, can solve the problems of instability, easy agglomeration, unfavorable storage and use, etc. The performance is unstable, the effect of improving the promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

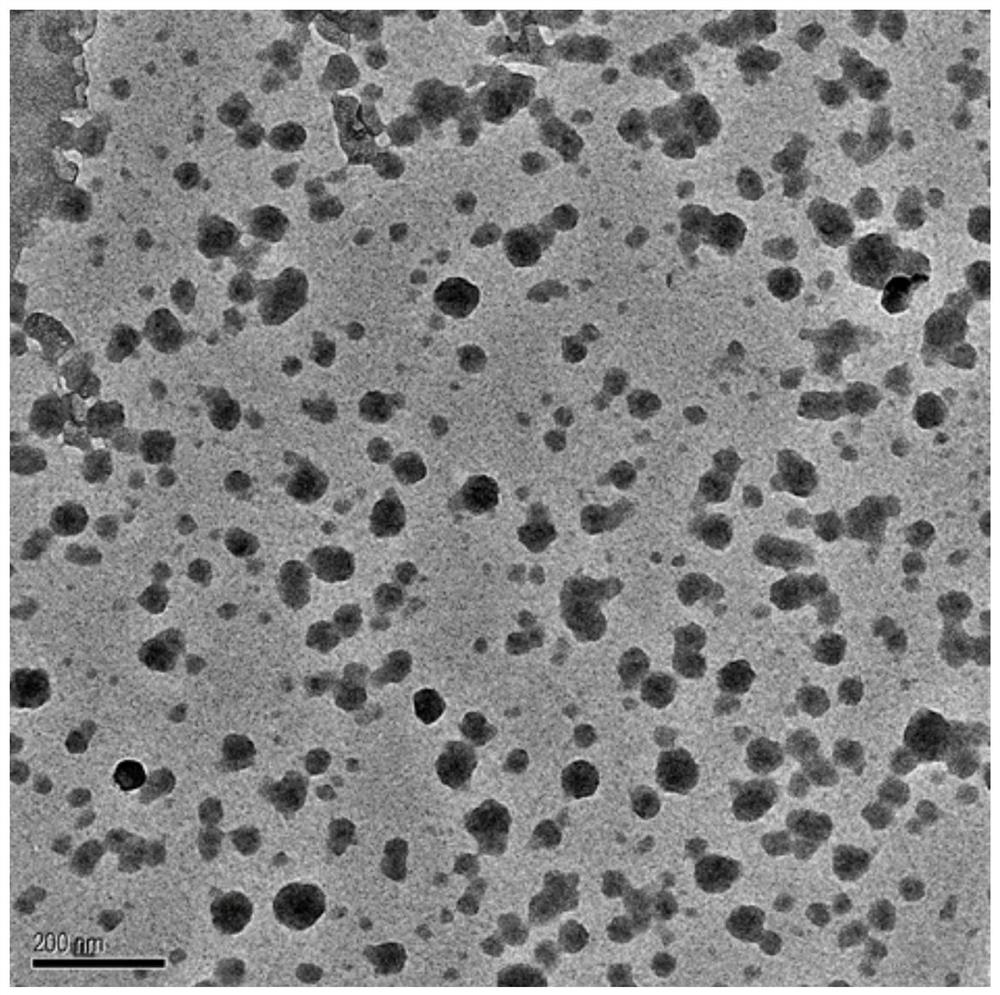

Embodiment 1

[0046] Weigh 17.2g of polycarboxylate superplasticizer and 100.0g of water, add them into the reaction kettle and start stirring, and set the stirring rate to 200rpm. Take by weighing 4.0g magnesium nitrate hexahydrate, 12.5g calcium nitrate tetrahydrate and 56.8g water are mixed and be configured into the mixed aqueous solution that effective concentration is 15wt%; Take by weighing 20.0g sodium metasilicate nonahydrate and 43.0g water are configured into effective concentration is 20wt% silicate aqueous solution, and finally weighed 2.4g of 30.0wt% nitric acid aqueous solution. Drop the above mixed aqueous solution, silicate aqueous solution and nitric acid aqueous solution into the reaction kettle, and control the dropping rate so that the dropping time is 3.0h. strong agent.

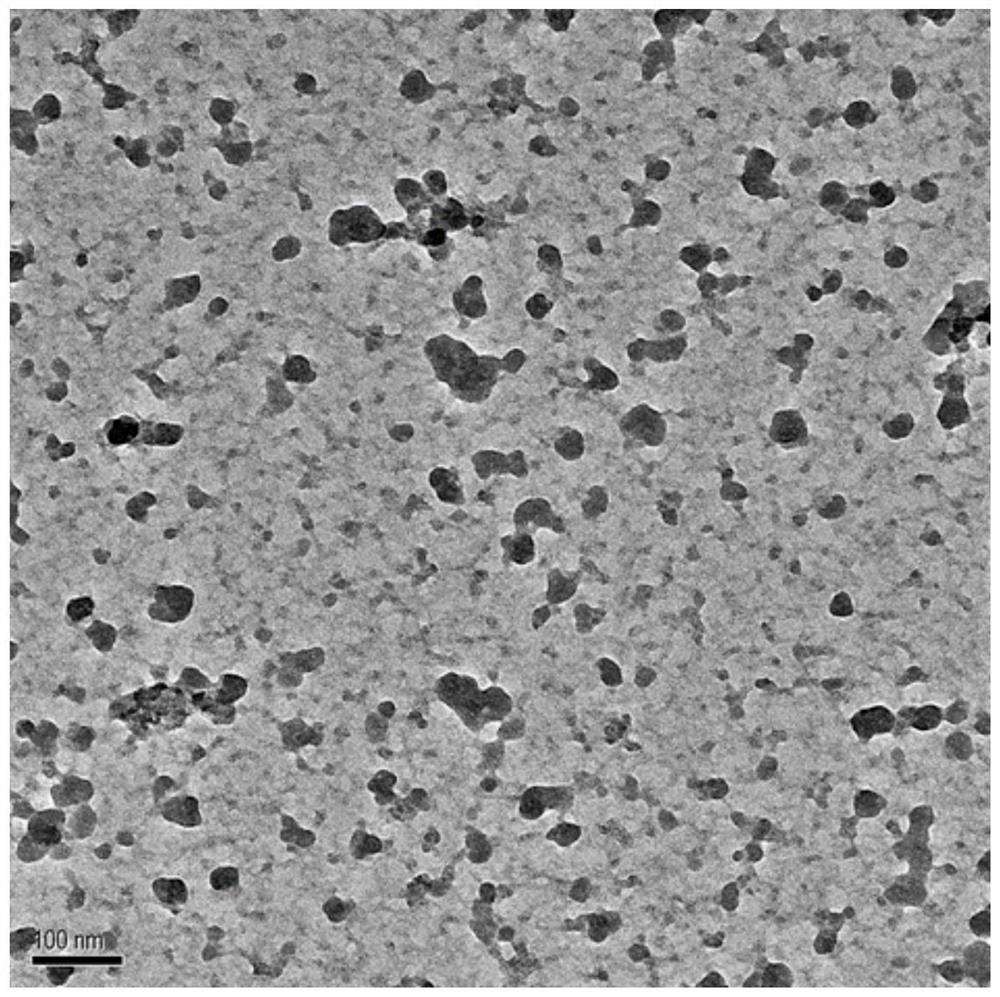

Embodiment 2

[0048] Weigh 15.0 g of polycarboxylate superplasticizer and 140.0 g of water, add them into the reaction kettle and start stirring, and set the stirring rate to 300 rpm. Take by weighing 3.0g magnesium nitrate hexahydrate, 10.4g calcium nitrate tetrahydrate and 22.6g water are mixed and be configured into the mixed aqueous solution that effective concentration is 25wt%; Take by weighing 8.5g sodium metasilicate pentahydrate and 23.5g water are configured into effective concentration is 15wt% silicate aqueous solution, and finally weighed 1.5g of 55.0wt% nitric acid aqueous solution. Drop the above mixed aqueous solution, silicate aqueous solution and nitric acid aqueous solution into the reaction kettle, and control the dropping rate so that the dropping time is 2.5 hours. strong agent.

Embodiment 3

[0050] Weigh 5.6g of polycarboxylate superplasticizer and 80.0g of water, add them into the reaction kettle and start stirring, and set the stirring rate to 250rpm. Weigh 0.5g magnesium nitrate hexahydrate, 3.8g calcium nitrate tetrahydrate and 34.6g water to mix and configure an effective concentration of 7.5wt% mixed aqueous solution; weigh 5.8g nonahydrate sodium metasilicate and 18.6g water to configure an effective concentration 10 wt% silicate aqueous solution, and finally weigh 1.0 g of 50.0 wt% nitric acid aqueous solution. Drop the above mixed aqueous solution, silicate aqueous solution and nitric acid aqueous solution into the reaction kettle, and control the dropping rate so that the dropping time is 2.0h. strong agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com