A kind of conductive composite material and its preparation method and application in lithium ion battery electrode

A technology of conductive composite materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve battery safety performance and cycle performance deterioration, increased lithium ion transmission paths, and pole piece pores The reduction of the rate and other problems, to achieve the effect of good conductivity, good ion conduction ability, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

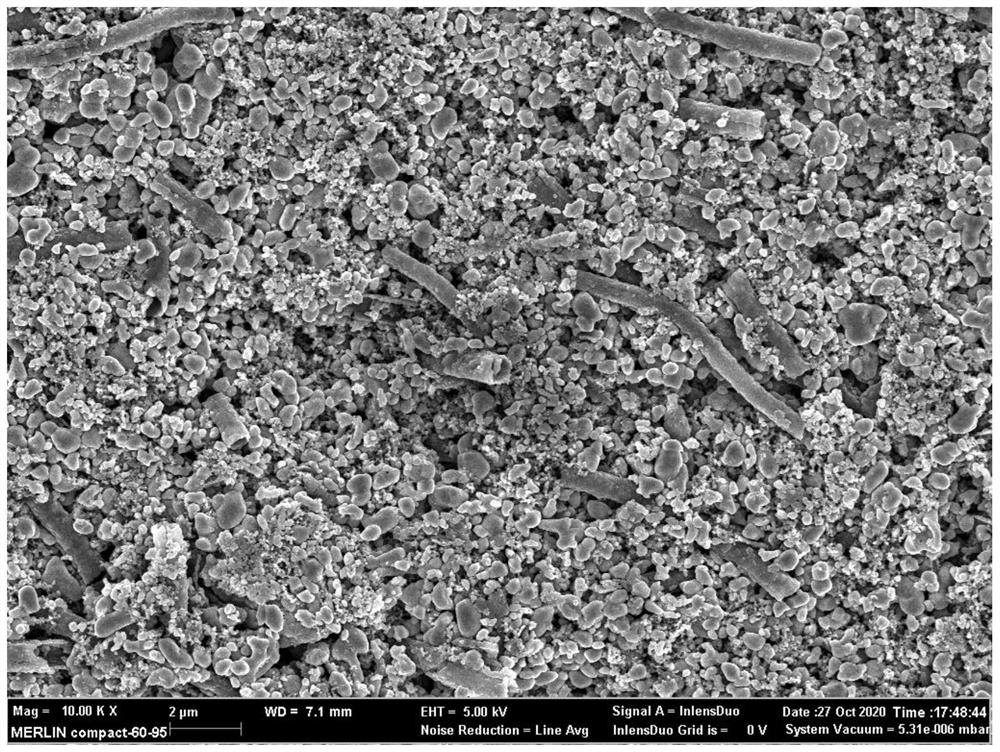

Image

Examples

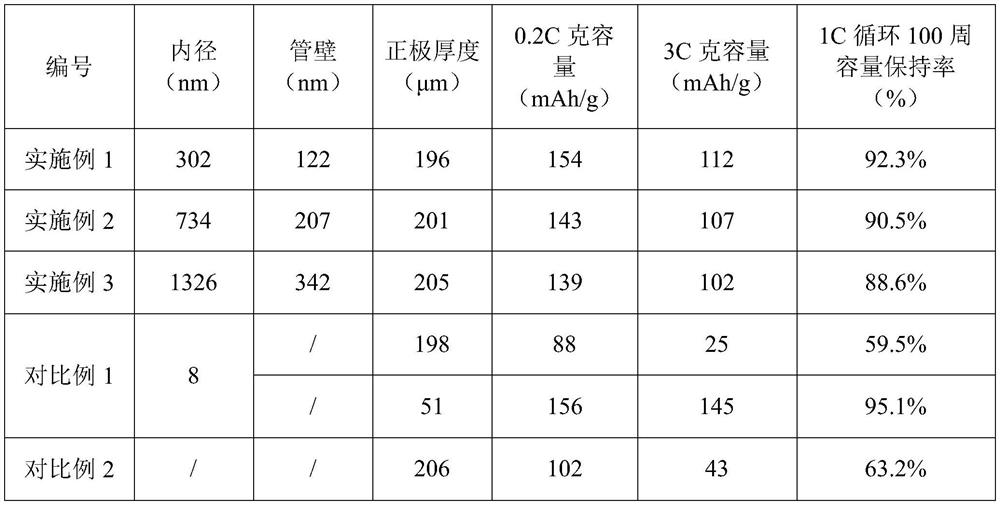

Embodiment 1

[0043] A preparation method of a conductive composite material is provided, which specifically comprises the following steps:

[0044]Step 1. Add polymethyl methacrylate and conductive material conductive carbon black into the organic solvent N,N-dimethylformamide, heat and stir at 40°C for 6 hours, and prepare the concentration of polymethyl methacrylate and conductive material to be 5 % of electrospinning solution A, wherein the mass ratio of conductive material to polymethyl methacrylate is 0.1:1. Electrospinning solution A was carried out by electrospinning equipment with a voltage of 10 kV, a spinning rate of 100 mL / min, and an electrode distance of 30 cm to obtain nanofibers with a diameter of 302 nm.

[0045] Step 2. Add the nanofibers obtained in step 1 into a 1 mol / L hydrochloric acid solution of aniline, the mass ratio of aniline and nanofibers is 0.8:1, stir at 500 rpm for 6h, and the nanofibers are uniformly dispersed to obtain mixed liquid B ;

[0046] Step 3. A...

Embodiment 2

[0049] A preparation method of a conductive composite material is provided, which specifically comprises the following steps:

[0050] Step 1: Add polystyrene and conductive material carbon nanotubes to the organic solvent dimethylfuran, heat and stir at 60°C for 3 hours, and prepare an electrospinning solution A with a concentration of polystyrene and conductive material of 10%. The mass ratio of polystyrene is 0.2:1. Electrospinning solution A was carried out by electrospinning equipment with a voltage of 20 kV, a spinning rate of 60 mL / min, and an electrode distance of 20 cm to obtain nanofibers with a diameter of 734 nm.

[0051] Step 2, adding the nanofibers obtained in step 1 into a 1 mol / L hydrochloric acid solution of pyrrole, the mass ratio of pyrrole and nanofibers being 0.9:1, and stirring at 1000 rpm for 4 hours to obtain mixed liquid B;

[0052] In step 3, hydrogen peroxide is added to the mixed liquid B obtained in step 2, and the mass ratio of pyrrole to hydrog...

Embodiment 3

[0055] A preparation method of a conductive composite material is provided, which specifically comprises the following steps:

[0056] Step 1, adding polyvinyl acetate and conductive material graphene into the organic solvent N-methylpyrrolidone, heating and stirring at 100° C. for 1 h to prepare an electrospinning solution A with a concentration of polyvinyl acetate and conductive material of 20%, conductive The mass ratio of material to polyvinyl acetate is 0.3:1. Electrospinning solution A was carried out by electrospinning equipment with a voltage of 30kV, a spinning rate of 20mL / min, and an electrode distance of 15cm to obtain nanofibers with a diameter of 1326nm.

[0057] Step 2, adding the nanofibers obtained in step 1 into a 1 mol / L hydrochloric acid solution of thiophene, the mass ratio of thiophene and the nanofibers being 1:1, and stirring at 2000 rpm for 2 hours to obtain mixed liquid B;

[0058] In step 3, ferric chloride is added to the mixed liquid B obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com