A multi-stage circulating jet spraying device for a packing-free cooling tower

A technology of spraying device and cooling device, applied in the field of cooling tower, can solve the problems of low efficiency, water vapor loss, waste, etc., and achieve the effect of good effect, reduced loss and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

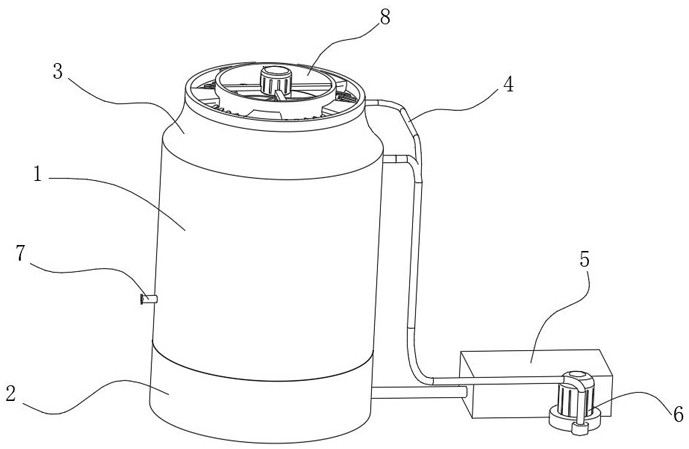

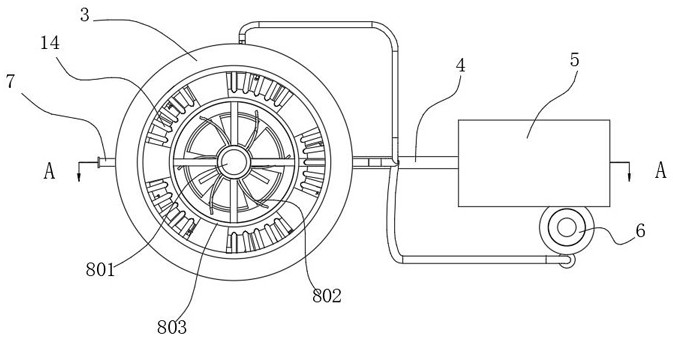

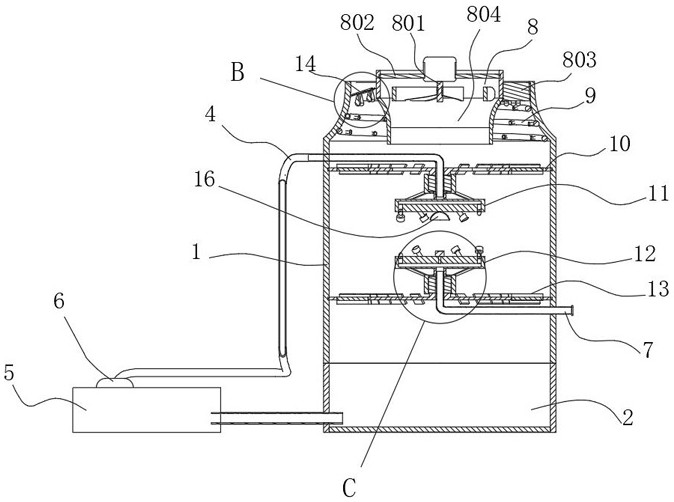

[0030] See Figure 1-8

[0031] In the present embodiment, the use of multi-stage cooling greatly improves the efficiency of heat exchange, and the multi-level water vapor recovery device can reduce the loss of water vapor, avoid waste, and water can be recycled to achieve high heat dissipation efficiency and less water vapor loss.

Embodiment 2

[0033] as Figure 1-8 As shown, on the basis of Example I, the present invention provides a technical solution: the secondary cooling device 9 is a spiral-shaped catheter, the outer wall of the secondary cooling device 9 is evenly distributed with several sprinkler heads 901.

[0034] In the present embodiment, the hot air mixed with water vapor inside the cooling tank 1 by the setting will rise along the inner wall of the cooling tank 1, when reaching the interior of the recovery cylinder 3, the spray head 901 outside the secondary cooling device 9 is sprayed out cold water to cool down again, and the spiral-shaped secondary cooling device 9 can be cooled at multiple levels, so that the cooling effect is better, the heat exchange is more complete, and most of the water vapor can be condensed into droplets after cold, reducing the loss of water vapor.

Embodiment 3

[0036] as Figure 1-8 As shown, on the basis of Example I, Example II, the present invention provides a technical solution: each steam recovery device 14 is tilted upwards from one end of the recovery cylinder 3, the bottom of each steam recovery device 14 is fixedly connected to at least one condensation block 1401, the condensation block 1401 is a small and large water droplet shape.

[0037] In the present embodiment, by the vapor recovery device 14 is provided, the condensed block 1401 at the bottom of the steam recovery device 14 due to the use of a streamlined water droplet state, the water vapor will move along the curved surface of the agglomeration block 1401, and finally crash into the steam recovery device 14, the water vapor condenses after liquefaction exothermic, the hot gas is blown out along the top of the recovery cylinder 3, and the liquefaction water flows into the interior of the cooling tank 1 along the slope of the steam recovery device 14, further to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com