Bisphenol A polymer modified polyacrylate water-based baking varnish and preparation method thereof

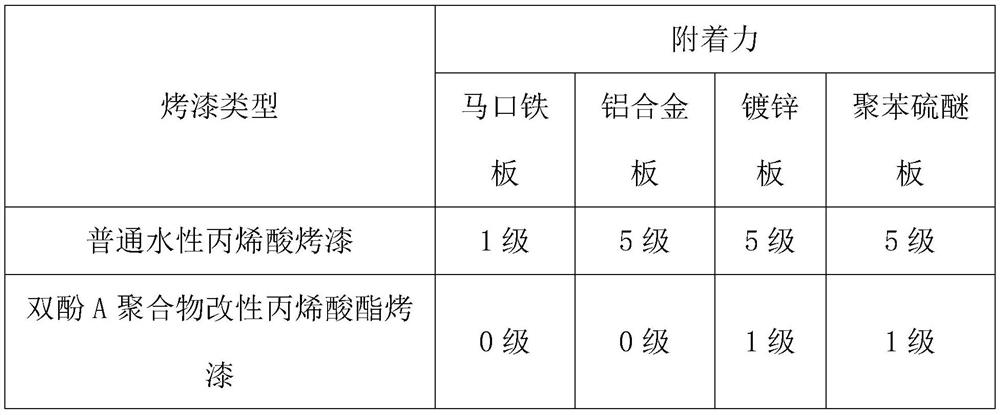

A technology of polyacrylate and methyl methacrylate, applied in the field of water-based baking varnish, which can solve the problems of application limitations and no adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] 1. bisphenol A polymer is made up of the raw material of following parts by weight: bisphenol A 40,128 epoxy resin 20, triphenylphosphine (10% n-butanol liquid) 0.15, lauric acid 40, the fourth group xylene 8 , the fifth group xylene 100;

[0042] The preparation steps of bisphenol A polymer are as follows:

[0043] A1. Add 128 epoxy resin and bisphenol A into a four-necked flask, raise the temperature to 80°C, start the mixer and add triphenylphosphine solution, stir well, then slowly raise the temperature to 110°C, stop heating, and wait for the heat release For the reaction, control the temperature at 145-150°C, and after maintaining for 30 minutes, take a sample to measure the epoxy value, and when the epoxy value is equal to zero, it is the end point;

[0044] A2. After reaching the end point, add lauric acid and the fourth group of xylene, and gradually raise the temperature to 160-170 to allow the esterification reaction;

[0045] A3. Keep reflux dehydration, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com