Process and device for continuously synthesizing tribromophenol by using microreactors

A microreactor, a technology of tribromophenol, applied in the field of tribromophenol synthesis, can solve the problems affecting the increase of the production capacity of tris(tribromophenoxy)triazine, prone to side reactions, low heat utilization rate, etc. The effect of occurrence of side reactions, small liquid holding capacity and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

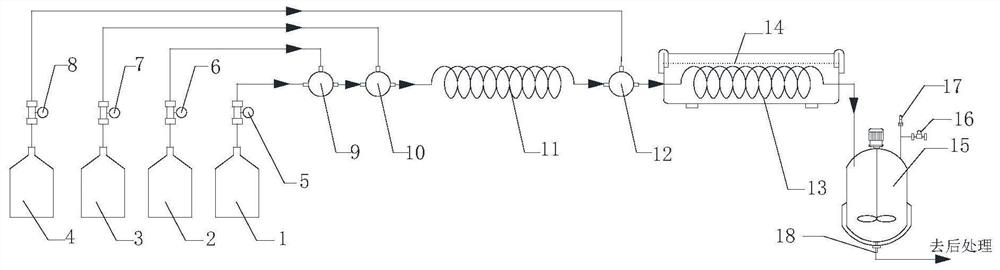

Embodiment 1

[0032] The flow rate of the metering pump is 47 g / min, and the flow rate of the metering pump 2 6 is 29.3 g / min, and the flow rate of the metering pump three 7 is 49.6 g / min, and the flow rate of the meter pump four 8 is 19.2g / min. The heating temperature of the water bath heater 14 was 75 ° C, the ripening kettle 15 temperature was controlled at 75 ° C, cooked for 30 min, and the cooked liquid was obtained by post-treatment to obtain tribromephenols, experimental results: 32min, total reaction time, 99.1% of triophenol .

Embodiment 2

[0034] The flow rate of the metering pump is 47 g / min, and the flow rate of the metering pump 2 6 is 28.3 g / min, and the flow rate of metering pump three 7 is 48 g / min, and the flow rate of metering pump four 8 is 18.8g / min, water bath The heating temperature of the heater 14 was 75 ° C, and the ripening kettle 15 temperature was controlled at 75 ° C, cooked for 30 min, and obtained trihydraminated liquid obtained by subjected to trihydrazhen, experimental results: 32 min of total reaction time and 98.9% of tribrominol.

Embodiment 3

[0036] The flow rate of the metering pump 1 5 is 47 g / min, and the flow rate of the metering pump 2 6 is 28.9 g / min, and the flow rate of the metering pump three 7 is 49 g / min, and the flow rate of the metering pump four 8 is 19g / min, the water bath heating The heating temperature of the unit 14 was 75 ° C, the ripening kettle 15 temperature was controlled at 75 ° C, cooked for 30 min, and obtained tropic liquid was treated with tribromol after treatment: 32 min, and a total rate of total reaction time was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com