High-chlorine fly ash cementing material and preparation method thereof

A technology for cementitious materials and fly ash, applied in the field of building materials, can solve the problems of small water-cement ratio control range, high requirements on working performance and mechanical properties of cementitious materials, slow reaction speed, etc., so as to achieve a perfect hardening system, The effect of promoting chemical binding capacity and reducing transport capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

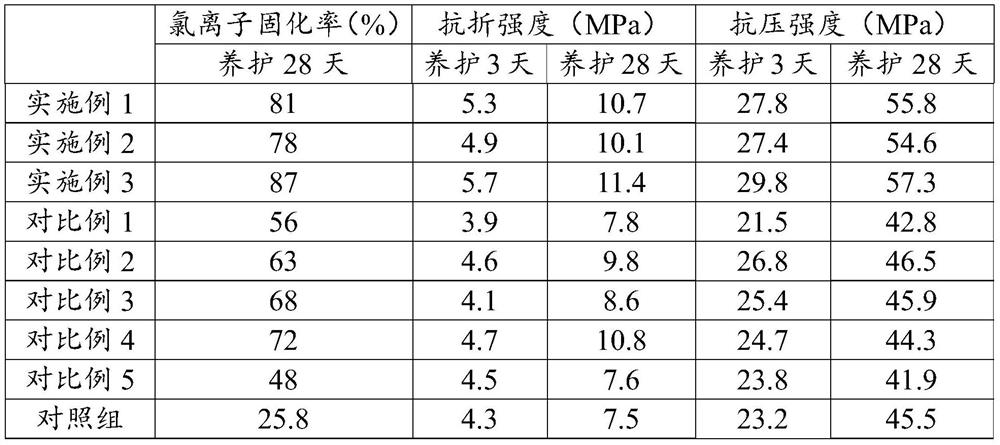

Examples

Embodiment 1

[0036] The raw material of high chlorine fly ash cementitious material described in the present embodiment comprises:

[0037] 60 parts by weight of high chlorine fly ash, 40 parts by weight of slag, 10 parts by weight of silica fume, 10 parts by weight of rice husk ash, 5 parts by weight of drought strength agent, and 3 parts by weight of alkali activator.

[0038] The preparation method of described high chlorine fly ash cementitious material, comprises the steps:

[0039] (1) Dry the high-chlorine pulverized coal at 105°C until the moisture content is ≤1%;

[0040] (2) After high-chlorine fly ash, slag, silica fume and rice husk ash are ball milled respectively, mix them evenly;

[0041] (3) uniformly mixing the mixture obtained in step (2) with an early strength agent and an alkali activator to obtain the high-chloride fly ash cementitious material.

[0042] The specific surface area of the high chlorine fly ash, slag, silica fume and rice husk ash after the ball milli...

Embodiment 2

[0044] The raw material of high chlorine fly ash cementitious material described in the present embodiment comprises:

[0045] 40 parts by weight of high chlorine fly ash, 60 parts by weight of slag, 30 parts by weight of silica fume, 20 parts by weight of rice husk ash, 1 part by weight of drought strength agent, and 1 part by weight of alkali activator.

[0046] The preparation method of described high chlorine fly ash cementitious material, comprises the steps:

[0047] (1) Dry the high-chlorine pulverized coal at 103°C until the moisture content is ≤1%;

[0048] (2) After high-chlorine fly ash, slag, silica fume and rice husk ash are ball milled respectively, mix them evenly;

[0049] (3) uniformly mixing the mixture obtained in step (2) with an early strength agent and an alkali activator to obtain the high-chloride fly ash cementitious material.

[0050] The specific surface area of the high chlorine fly ash, slag, silica fume and rice husk ash after the ball milling...

Embodiment 3

[0052] The raw material of high chlorine fly ash cementitious material described in the present embodiment comprises:

[0053] 90 parts by weight of high chlorine fly ash, 30 parts by weight of slag, 20 parts by weight of silica fume, 30 parts by weight of rice husk ash, 3 parts by weight of drought strength agent, and 10 parts by weight of alkali activator.

[0054] The preparation method of described high chlorine fly ash cementitious material, comprises the steps:

[0055] (1) Dry the high-chlorine pulverized coal at 107°C until the moisture content is ≤1%;

[0056] (2) After high-chlorine fly ash, slag, silica fume and rice husk ash are ball milled respectively, mix them evenly;

[0057] (3) uniformly mixing the mixture obtained in step (2) with an early strength agent and an alkali activator to obtain the high-chloride fly ash cementitious material.

[0058] The specific surface area of the high chlorine fly ash, slag, silica fume and rice husk ash after the ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com