3D printed bioscaffold with drug release function and preparation method thereof

A 3D printing and bio-scaffold technology, which is applied in the fields of pharmaceutical formulation, drug delivery, medical science, etc., can solve the problems of difficult drug slow release, difficult drug controlled release, difficult loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

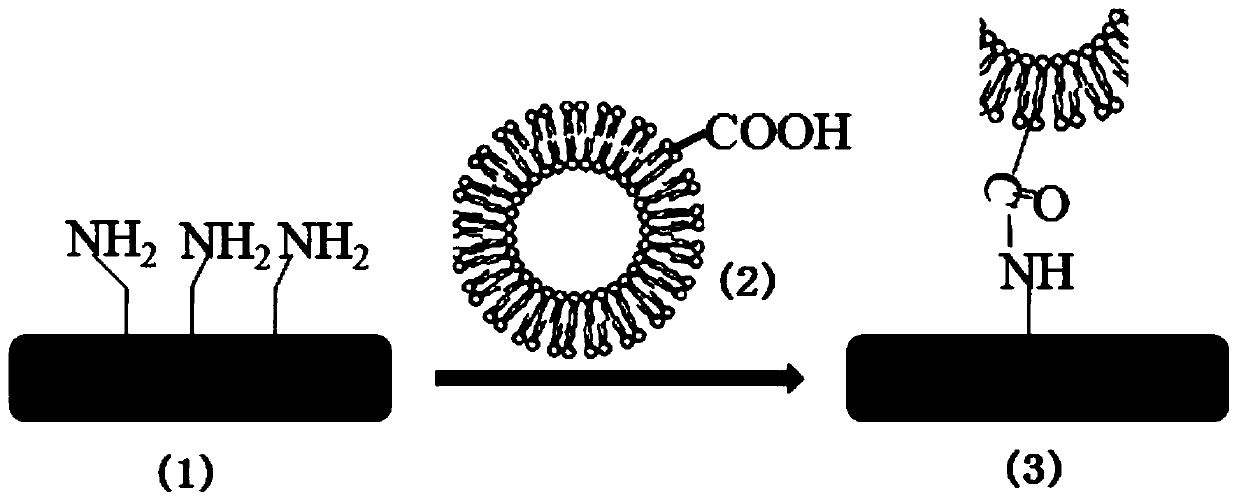

[0042] After mixing 1 g of PLLA and 0.13 g of KH550 (aminopropyltriethoxysilane), 3D printing was carried out to obtain a 3D printed scaffold with surface amination.

[0043] According to the molar ratio of 96:19:4:20, weigh dipalmitoylphosphatidylcholine, cholesterol, DSPE-PEG-COOH (phosphatidylethanolamine-polyethylene glycol-carboxy) and paclitaxel, and dissolve it with 30mL chloroform Transfer to an eggplant-shaped bottle. The lipid film was obtained after the solvent was evaporated by rotary evaporation, and dried in vacuum overnight. Add 20 mL of PBS to the eggplant-shaped bottle for hydration to obtain liposome crude emulsion. The liposome coarse emulsion was processed with an ultrasonic probe, the ultrasonic time was 3 minutes, the ultrasonic power was 40%, and the operation was 2 seconds and the stop was 1 second. The sonicated liposome solution is sequentially passed through 0.8 μm, 0.45 μm, and 0.22 μm microporous membranes to obtain a liposome solution modified w...

Embodiment 2

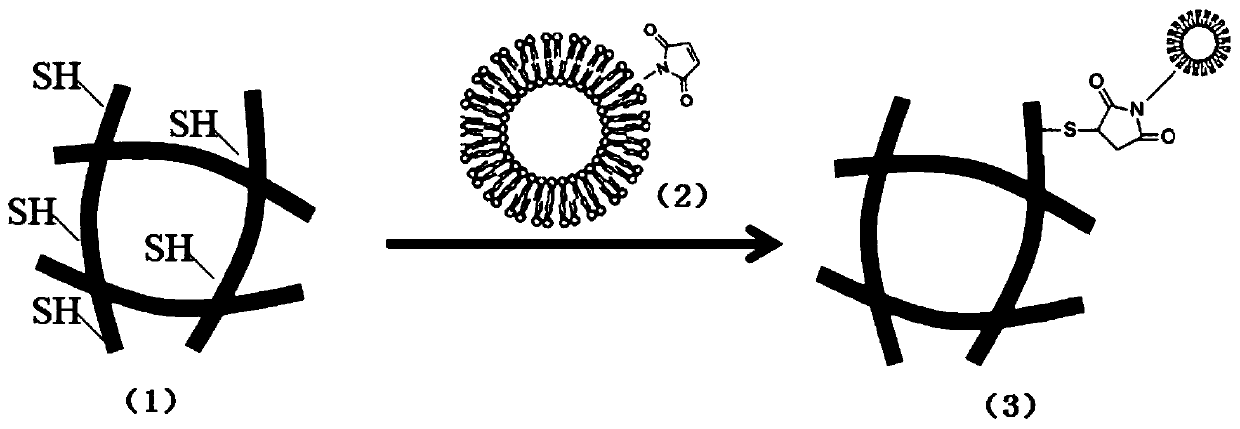

[0047] The cleaned and dried 3D printed scaffold (made of PLLA) was soaked in 6wt% hexamethylenediamine / n-propanol solution and shaken at 60°C for a certain period of time, then washed repeatedly with ethanol and deionized water and dried in vacuum to obtain amino-functionalized scaffolds. 3D printed brackets.

[0048] According to the molar ratio of 80:40:4:20, weigh soybean lecithin, cholesterol sulfate, DSPE-PEG-COOH (phosphatidylethanolamine-polyethylene glycol-carboxy) and ibuprofen, then dissolve them with 30mL chloroform and transfer into an eggplant-shaped bottle. The lipid film was obtained after the solvent was removed by rotary evaporation, and the organic residue was removed by vacuum drying overnight. Add 20 mL of PBS to the eggplant-shaped bottle for hydration to obtain liposome crude emulsion. The liposome coarse emulsion was processed with an ultrasonic probe, the ultrasonic time was 3 min, the ultrasonic power was 20%, and the working time was 1 second and t...

Embodiment 3

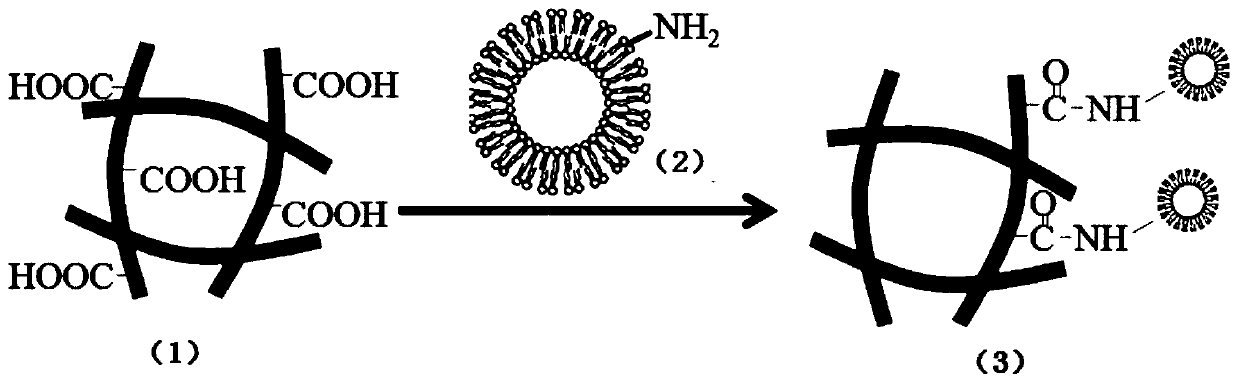

[0051] Using 3D printing technology to print out the PCL bioscaffold. Plasma treatment was performed on the bracket, as follows: the 3D printed bracket was placed in the plasma device and fixed between the electrodes, and when the pressure in the inner chamber reached 10 -3 At Torr, inject oxygen and gaseous acrylic acid at 0.2 Torr, and apply radio frequency power of 50W and negative electrode pulse voltage for 30s to obtain a 3D printed scaffold with carboxyl groups on the surface.

[0052] According to the molar ratio of 90:30:3:15, weigh egg yolk lecithin, cholesterol, DSPE-PEG-NH 2 (phosphatidylethanolamine-polyethylene glycol-amino) and doxorubicin, and dissolve it in 2mL ethanol solution to obtain a lipid ethanol solution. Measure 20 mL of PBS solution and place it in a beaker, and add the lipid ethanol solution dropwise into the beaker under the conditions of a rotating speed of 300 rpm and a temperature of 40°C. After the dropwise addition is completed, continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com