A kind of cobalt-free cathode material slurry and its preparation method and application

A cathode material and slurry technology, applied in the field of cobalt-free cathode material slurry and its preparation, can solve the problems of complex preparation method and high cost of cathode material, and achieve the effects of reducing the generation of impurities, stable performance and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

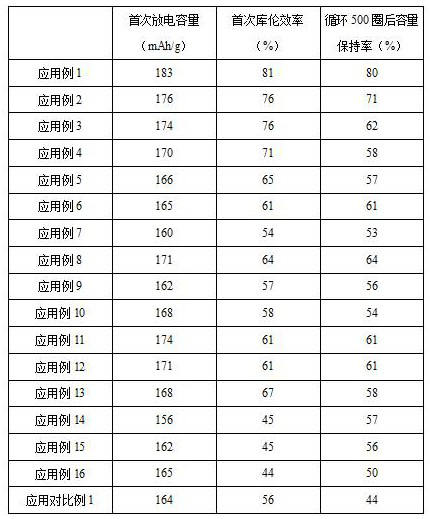

Examples

Embodiment 1

[0041] This embodiment provides a cobalt-free cathode material slurry, which is composed of 95 parts by weight of a cobalt-free cathode material (LiNi 0.7 mn 0.3 o 2 ), 1.5 parts of binder (polyvinylidene fluoride, purchased from Sinopharm Chemical Reagent Network), 3.5 parts of conductive agent (conductive carbon black, purchased from Pioneer Technology), 30 parts of solvent (NMP) and 2 parts of unsaturated bond-containing Composition of sulfone compounds (DVS).

[0042] The preparation method of the above-mentioned cobalt-free cathode material slurry comprises the following steps:

[0043] After mixing the cobalt-free positive electrode material, the binder, the conductive agent and the solvent, add a sulfone compound containing an unsaturated bond, and mix uniformly at 25° C. to obtain the cobalt-free positive electrode material slurry.

Embodiment 2-5

[0045] The difference between Examples 2-5 and Example 1 is that the parts by weight of DVS are 3 parts, 4 parts, 5 parts and 6 parts respectively, and the rest are the same as Example 1.

Embodiment 6

[0047] This embodiment provides a cobalt-free cathode material slurry, which is composed of 95 parts by weight of a cobalt-free cathode material (Li 1.1 Ni 0.8 mn 0.2 o 2 ), 1 part of binder (polyacrylic acid, purchased from Sinopharm Chemical Reagent Network), 3 parts of conductive agent (carbon nanotubes, purchased from Pioneer Technology), 25 parts of solvent (NMP) and 1 part of sulfone containing unsaturated bonds compound (DVS) composition.

[0048] The preparation method of the above-mentioned cobalt-free cathode material slurry comprises the following steps:

[0049] After mixing the cobalt-free positive electrode material, binder, conductive agent and solvent, add a sulfone compound containing an unsaturated bond, and mix uniformly at 45° C. to obtain the positive electrode material slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com