Process method for synthesizing tin disulfide nanosheet by taking nitrogen-doped multi-walled carbon nanotube as carrier

A technology of multi-walled carbon nanotubes and tin disulfide, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unsatisfactory needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

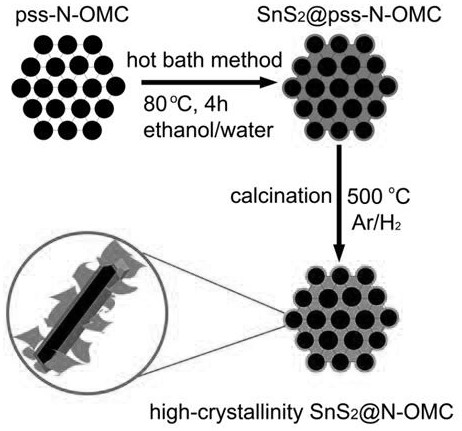

[0033] A process method for synthesizing tin disulfide nanosheets with nitrogen-doped multi-walled carbon nanotubes as a carrier, which is realized by the following steps:

[0034] 1) Synthesis of ordered mesoporous carbon CMK-3 by incipient wetness of silica SBA-15 and treatment with nitrogen-containing precursors to obtain N-MWCNTS, nitrogen-doped multi-walled carbon nanotubes;

[0035] 2) Dissolve 100mg of polystyrene sulfonic acid pss in 50mL of sodium chloride solution dispersion under stirring and keep for 30 minutes;

[0036] 3) 100 mg of N-MWCNTS was added to the mixture obtained in step 2), and the resulting solution was subjected to intense sonication for 30 minutes, followed by stirring for two hours;

[0037] 4) After the solution obtained in step 3) was washed several times with distilled water and ethanol, the precipitate was collected by centrifugation, and finally the precipitate was dried at 60 °C for 8 h to obtain pss-N-MWCNTS.

[0038] 5) Dissolve 0.4 g of ...

Embodiment 2

[0043] A process method for synthesizing tin disulfide nanosheets with nitrogen-doped multi-walled carbon nanotubes as a carrier, which is realized by the following steps:

[0044] 1) Synthesis of ordered mesoporous carbon CMK-3 by incipient wetness of silica SBA-15 and treatment with nitrogen-containing precursors to obtain N-MWCNTS, nitrogen-doped multi-walled carbon nanotubes;

[0045] 2) Dissolve 100mg of polystyrene sulfonic acid pss in 50mL of sodium chloride solution dispersion under stirring and keep for 30 minutes;

[0046] 3) 100 mg of N-MWCNTS was added to the mixture obtained in step 2), and the resulting solution was subjected to intense sonication for 30 minutes, followed by stirring for two hours;

[0047] 4) After the solution obtained in step 3) was washed several times with distilled water and ethanol, the precipitate was collected by centrifugation, and finally the precipitate was dried at 60 °C for 8 h to obtain pss-N-MWCNTS.

[0048] 5) Dissolve 0.8 g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com