Formamidino perovskite thin film, perovskite battery assembly and preparation method of formamidino perovskite thin film

A formamidine-based perovskite and amidine-based perovskite technology, applied in the field of perovskite solar cells, can solve problems such as difficult control, achieve the effects of saving dosage, reducing production costs, and being easy to scale up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

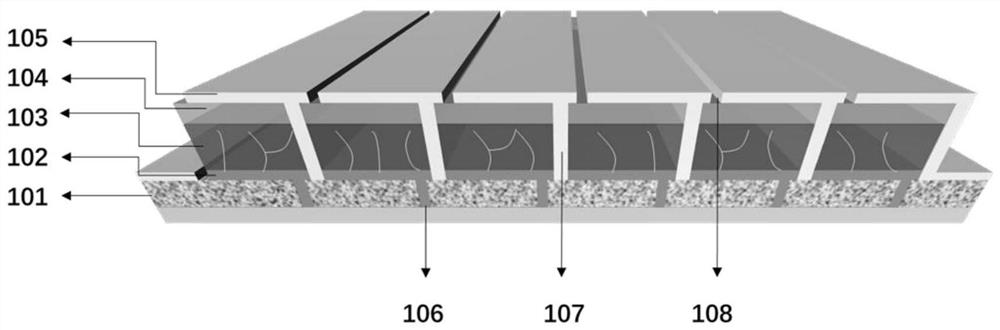

[0058] refer to figure 1 , a perovskite cell assembly, comprising an FTO transparent conductive substrate 101, a tin dioxide electron transport layer 102, a formamidinium-based perovskite light-absorbing layer 103, a Spiro-OMeTAD hole transport layer 104 and Metal electrode 105 . The FTO transparent conductive substrate 101 is etched to form an etch pattern P1 106, and the tin dioxide electron transport layer 102, the formamidinium-based perovskite light absorption layer 103 and the Spiro-OMeTAD hole transport layer 104 are etched to form an etch pattern P2 107, cutting the metal electrode 105 to form an etching pattern P3 108.

[0059] The preparation method of the perovskite battery component includes the following steps:

[0060] (1) Prepare the transparent conductive substrate

[0061] First, cut the FTO conductive glass into the required size (10cm×10cm), and use the laser to etch the P1. Then, the glass was ultrasonically cleaned with glass cleaning solution, pure wa...

Embodiment 2

[0079] The difference between this example and Example 1 is that the perovskite composition ratio in the precursor solution of this example is FAPbI 3 , the composition of the precursor solution is: 143 mg of formamidine iodide, 461 mg of lead iodide, and 900 μL of DMF. And add high donor number solvent DMPU 130μL, DMPU and perovskite component FAPbI 3 The molar mass ratio is 1:1. Other operations are the same as in Example 1.

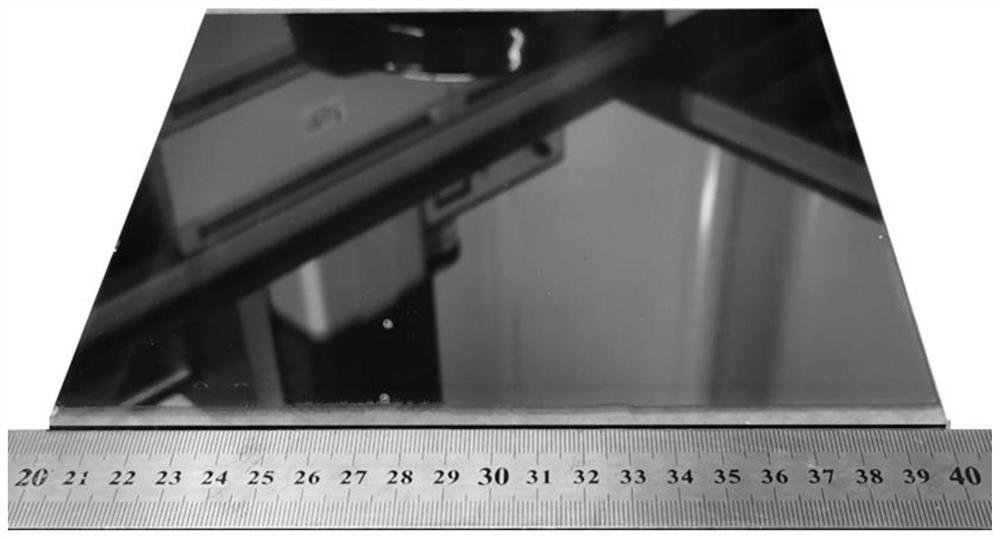

[0080] Efficiency test: Under AM 1.5G sunlight intensity, the effective area is 65cm 2 100cm measured under the mask 2 The photoelectric conversion efficiency of the perovskite cell module is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com