Anti-corrosion washing machine cover plate and production spraying process thereof

A washing machine cover and process technology, applied to anti-corrosion coatings, other washing machines, coatings, etc., can solve the problems of easy corrosion of the washing machine cover, achieve the effect of convenient cleaning and drying, and reduce contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

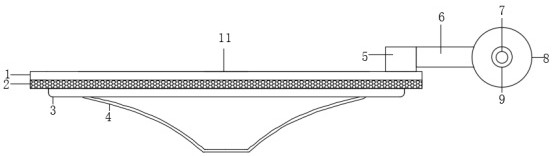

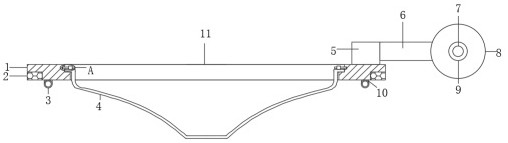

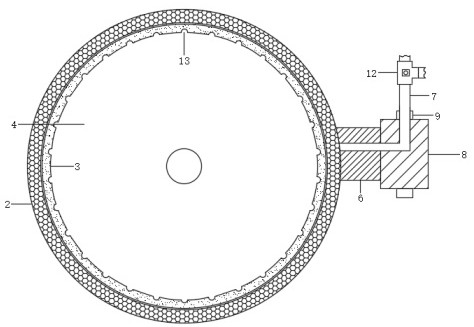

[0032] refer to Figure 1-4 : A kind of anti-corrosion washing machine cover plate, comprises circular plate 1, offers T-shaped through-hole in the middle of circular plate 1, and the inside of T-shaped through-hole is provided with observation device, and the right side of circular plate 1 is provided with connecting device, and the inside of connecting device A conveying device is provided, a cleaning device is provided at the bottom of the disc 1 , and a fixed ring 2 is fixed at the bottom of the disc 1 .

[0033] In this embodiment, the observation device includes a glass plate 4, the top of the glass plate 4 is movably sleeved inside the T-shaped through hole, the overall shape of the glass plate 4 is like a bowl, and the bowl-shaped glass plate 4 cooperates with the mechanical vibration of the washing machine , which can make the splashed liquid slide down automatically.

[0034] In this embodiment, the connection device includes a rectangular block 5 fixedly connected ...

Embodiment 2

[0039] A kind of antiseptic washing machine cover plate production spraying process, in the present embodiment, comprises the following steps:

[0040] S1, the selection of materials, select polytetrafluoroethylene as the raw material for making the cover plate of the washing machine;

[0041] S2, forming, melting the polytetrafluoroethylene in S1, then pouring it into the mold, taking it out and cooling slowly to obtain a blank;

[0042] S3, the surface treatment of the blank, the blank obtained in S2 is polished and burred, and rinsed with hot water for 10-15min;

[0043] S4, the blank is sprayed for the first time, and 7.5%-10% butanol etherified phenolic resin, 10%-15% epoxy resin, and 6%-10% fluorine polyurethane are added to the spraying liquid for the blank in S3;

[0044] S5, drying, drying with hot air at 30°C-40°C;

[0045] S6, secondary spraying, in the spraying liquid, add 7.5%-10% butanol etherified phenolic resin, 10%-15% epoxy resin, 15%-20% fluorine polyureth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com