Bottle washing device capable of adjusting fixed height and used for production line

A washing device and production line technology, which is applied in the direction of cleaning hollow objects, progressive dryers, dryers, etc., can solve the problems of large investment in production and large production line area, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

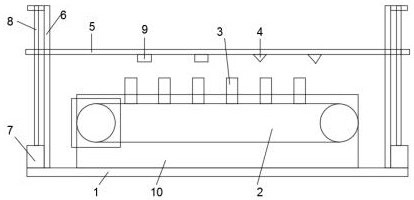

[0019] see figure 1 , a production line bottle 3 washing device, a production line bottle 3 washing device, including a base 1, the base 1 is provided with a conveying mechanism for conveying the bottle 3, the conveying mechanism is a conveyor belt 2, and the conveying belt 2 Several bottles 3 are transported equidistantly on the top, a frame is arranged above the conveyor belt 2, and a flushing mechanism is arranged on the frame, and the flushing mechanism includes a plurality of spray heads 4 arranged at the bottom end of the frame. 4 is a high-pressure nozzle 4. The spraying angle of the spray head 4 is 180°, and the lower end of the frame is provided with a lifting mechanism, and the lifting mechanism is used to drive the frame to move upward.

[0020] In this embodiment, the frame includes a horizontal frame 5 and a vertical frame 6 , the left and right ends of the horizontal frame 5 are sleeved on the vertical frame 6 , and the vertical frame 6 is fixed on the base 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com