Combined treatment method of copper-containing sludge and copper-containing etching waste liquid

A combined processing and copper etching technology, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high acid consumption cost and high disposal cost, so as to protect the environment, reduce acid and alkali consumption, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

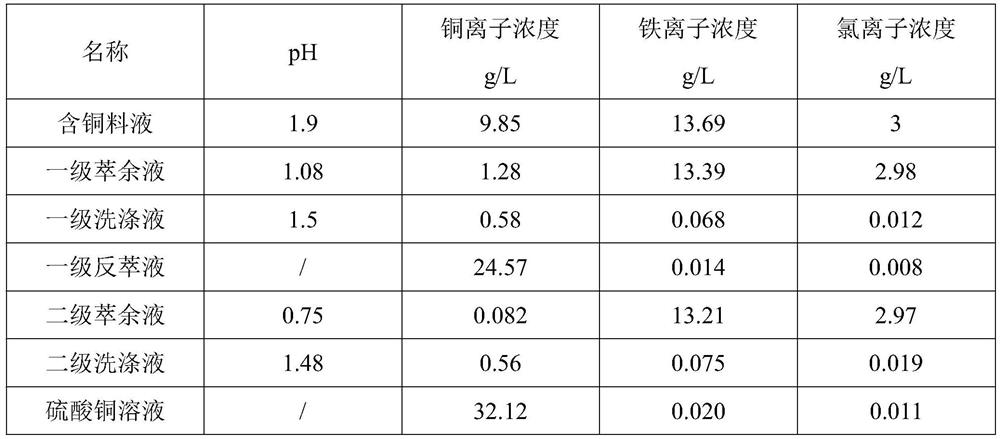

Embodiment 1

[0047] Using acidic copper-containing etching waste liquid and copper-containing sludge produced by a circuit board factory as raw materials: the concentration of copper chloride in the acidic copper-containing etching waste liquid is 15.28%, converted into Cu 2+ Concentration is 72.44g / L, H + The concentration is 1.81mol / L; the dry base copper content of the copper-containing sludge is 12.94%, and the moisture content is 68.5%.

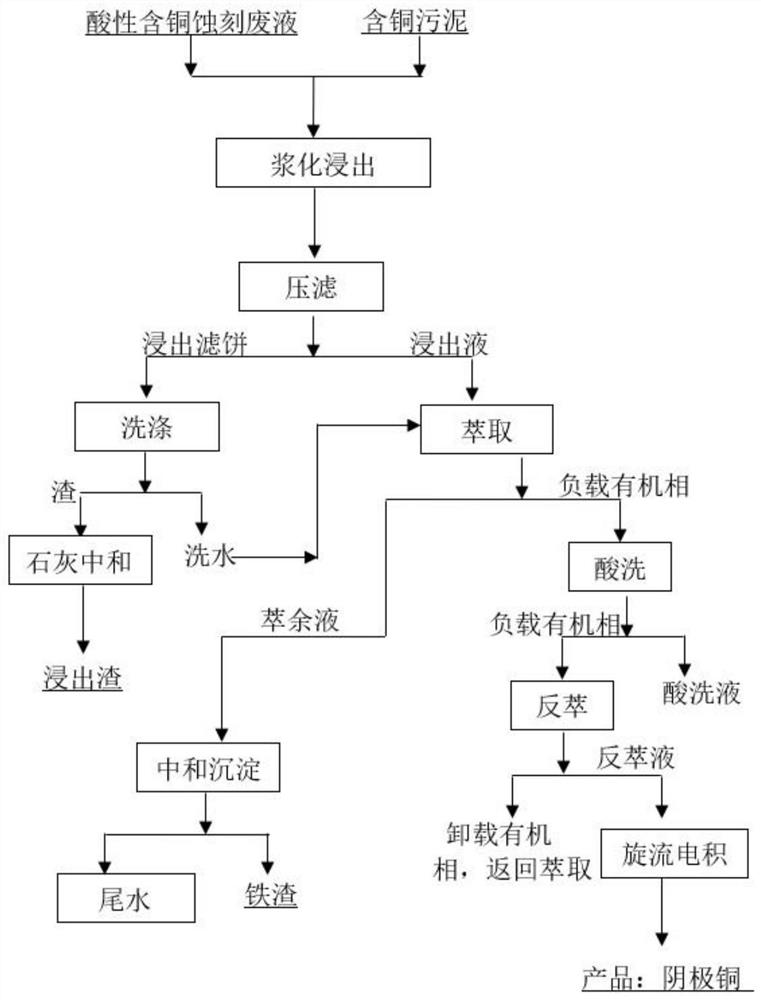

[0048] A kind of combined treatment method of copper-containing sludge and copper-containing etching waste liquid, such as figure 1 As shown, the following steps are involved:

[0049] (1) Leaching: Weigh 100g of the above-mentioned acidic copper-containing etching waste liquid and 200g of the above-mentioned copper-containing sludge to make pulp together, add water to adjust the solid-liquid ratio to 1:7, add concentrated sulfuric acid with an industrial mass concentration of 98%, and adjust the pH of the slurry To 1.8, the final acid consumption ...

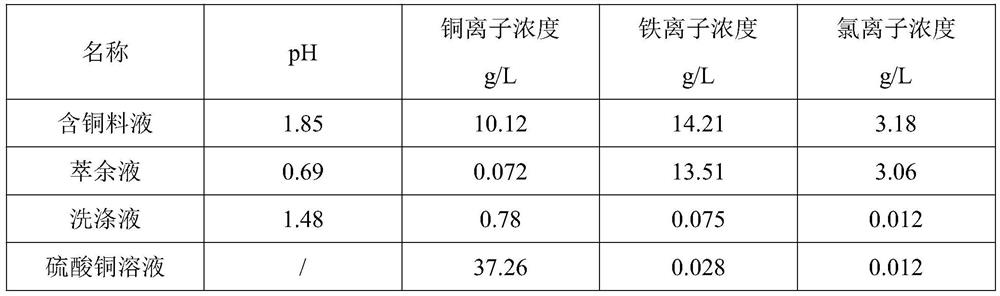

Embodiment 2

[0062] Using acidic copper-containing etching waste liquid and copper-containing sludge produced by a circuit board factory as raw materials: the concentration of copper chloride in the acidic copper-containing etching waste liquid is 15.28%, converted into Cu 2+ Concentration is 72.44g / L, H + The concentration is 1.81mol / L; the dry base copper content of the copper-containing sludge is 12.94%, and the moisture content is 68.5%.

[0063] A method for joint treatment of copper-containing sludge and copper-containing etching waste liquid, comprising the following steps:

[0064] (1) Leaching: Weigh 10kg of the above-mentioned acidic copper-containing etching waste liquid and 20kg of the above-mentioned copper-containing sludge to make pulp together, add water to adjust the solid-liquid ratio to 1:7, add concentrated sulfuric acid with an industrial mass concentration of 98%, and adjust the pH of the slurry to 1.85, the final acid consumption is 2.18kg, the reaction is 4-6h, and...

Embodiment 3

[0075] The concentration of copper chloride in the acidic copper-containing etching waste liquid is 15.28%, converted into Cu 2+ Concentration is 72.44g / L, H + The concentration is 1.81mol / L; the dry base copper content of the copper-containing sludge is 12.94%, and the moisture content is 68.5%.

[0076] A method for joint treatment of copper-containing sludge and copper-containing etching waste liquid, comprising the following steps:

[0077] (1) Leaching: Take 2t of the above-mentioned acidic copper-containing etching waste liquid and 4t of the above-mentioned copper-containing sludge to make pulp together, add water to adjust the solid-liquid ratio to 1:8, add concentrated sulfuric acid with an industrial mass concentration of 98%, and adjust the pH of the slurry to 1.78, the final acid consumption is 385Kg, the reaction is 6h, and the solid-liquid separation obtains leaching residue and copper-containing feed liquid.

[0078] (2) Washing and neutralization: add water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com