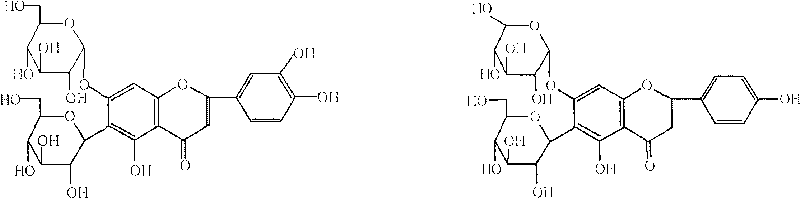

Novel process for preparing highland barley flavone extract and application thereof in health wine

A technology of highland barley flavonoids and extracts, which is applied in the preparation of sugar derivatives, alcoholic beverages, sugar derivatives, etc., can solve the problems of troublesome classification process, high energy consumption in the production process, poor separation reproducibility, etc., and achieve the product Good stability, reduced acid and alkali consumption, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Get dry highland barley seedling raw material 10Kg, cut into the small section of 1~2cm or pulverize into coarse powder, use 10 times of raw material weight amount, the ethanol solution that concentration is 10%, at temperature 70 ℃, use Wuhan Huipeng pharmaceutical machinery The TQ-300 small multi-functional extraction unit produced by Equipment Co., Ltd. extracts 1 to 4 times, each time for 0.5 to 4 hours, and the extract is obtained after filtering and sedimenting through the bottom screen of the extraction tank of the multi-functional extraction unit; The SHB-C vacuum pump produced by the limited company pumps air and reduces pressure, recovers the ethanol in the extract until the alcohol concentration is less than 5%, and obtains a concentrated solution of 30Kg.

[0028] After diluting the concentrated solution with 2 times the amount of 60Kg pure water, use the GQ75 tubular centrifuge produced by Shanghai Pudong Tianben Centrifugal Machinery Co., Ltd. ...

Embodiment 2

[0033] Embodiment 2 Get dry highland barley seedling raw material 10Kg, be cut into the subsection of 1~2cm or be pulverized into coarse powder, use the ethanol solution that 20 times of raw material weight, concentration are 60%, use small-scale multifunctional extraction unit at temperature 80 ℃ Extract 1 to 4 times, each time for 0.5 to 4 hours, and obtain the extract after filtering the precipitate through the bottom screen of the extraction tank of the multifunctional extraction unit; After the concentration is less than 5%, 25Kg of concentrated solution is obtained.

[0034] After the concentrated solution is diluted with 2 times the amount of 50Kg pure water, it is centrifuged at a speed of 20000 rpm with a GQ75 type tubular centrifuge to remove suspended particulate impurities such as dust to obtain 75Kg of the centrifuge.

[0035] The centrifugate was filtered with a SJM-FHM-10 type 100nm ceramic microfiltration membrane device to obtain 100Kg of clarified liquid (40K...

Embodiment 3

[0039] Embodiment 3 Get dry highland barley seedling raw material 10Kg, cut into the segment of 1~2cm or pulverize into coarse powder, use 25 times of raw material weight amount, concentration be the ethanol solution of 40%, use TQ-300 small multi-purpose at temperature 90 ℃. The functional extraction unit extracts 1 to 4 times, each time for 0.5 to 4 hours, and the extract is obtained after filtering and sedimenting through the bottom screen of the extraction tank of the multifunctional extraction unit; After ethanol reaches the concentration of alcohol < 5%, 28Kg of concentrated solution is obtained.

[0040] After the concentrated solution is diluted with 2 times the amount of 56Kg pure water, it is centrifuged at a speed of 20000 rpm with a GQ75 type tubular centrifuge to remove suspended particulate impurities such as dust to obtain 83Kg of the centrifuge.

[0041]The centrifugal liquid adopts SJM-FHM-10 type 50nm ceramic microfiltration membrane equipment to filter, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com