Preparation method of water-based photoresponse self-repairing leather finishing agent

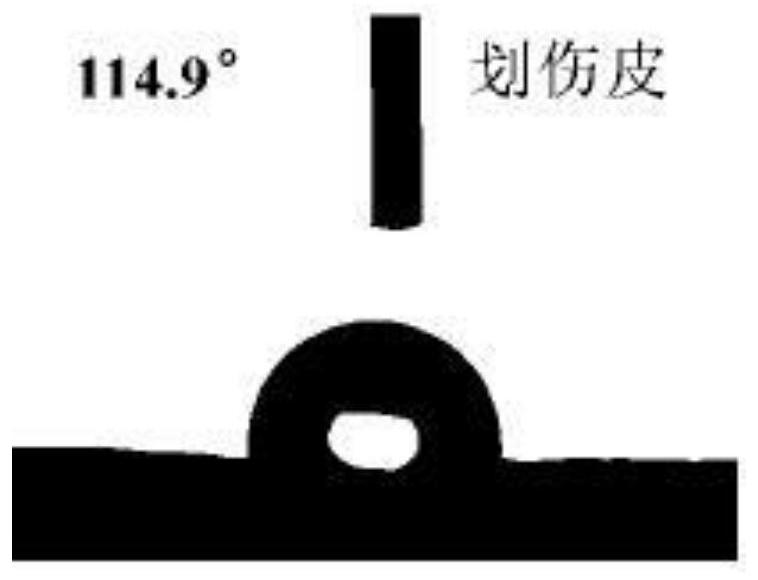

A leather finishing agent and light-responsive technology, which is applied in leather surface treatment, textile/flexible product manufacturing, small raw leather/big raw leather/leather/fur treatment, etc. It can solve the problem of no self-healing ability and solve the problem of surface damage , good stability and good self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

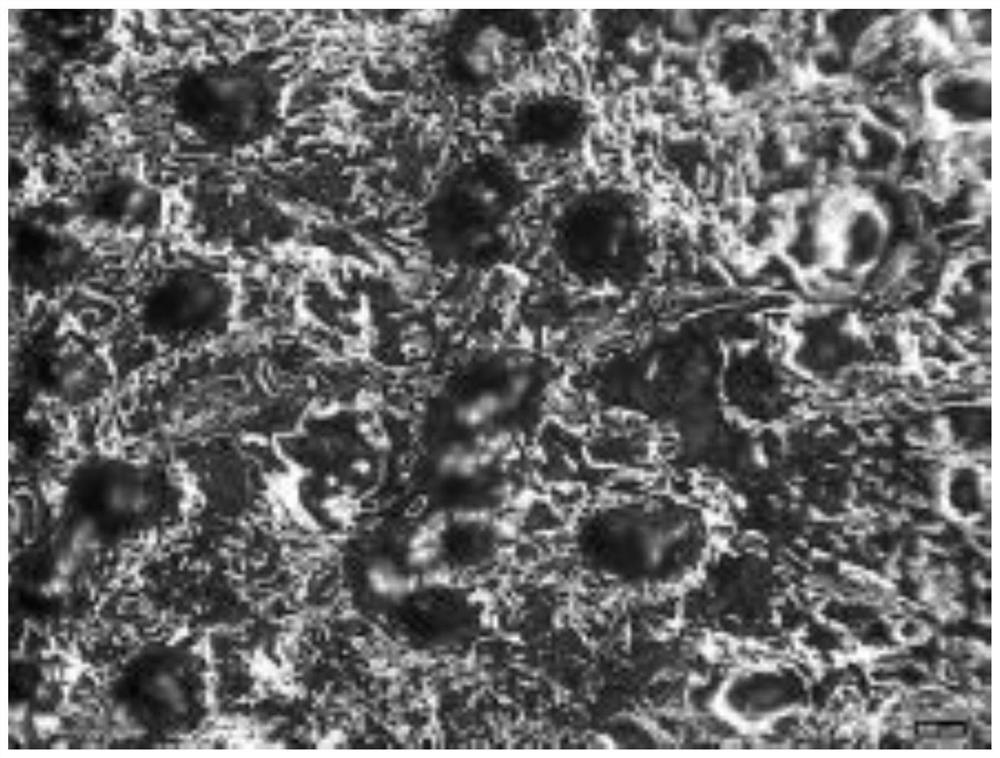

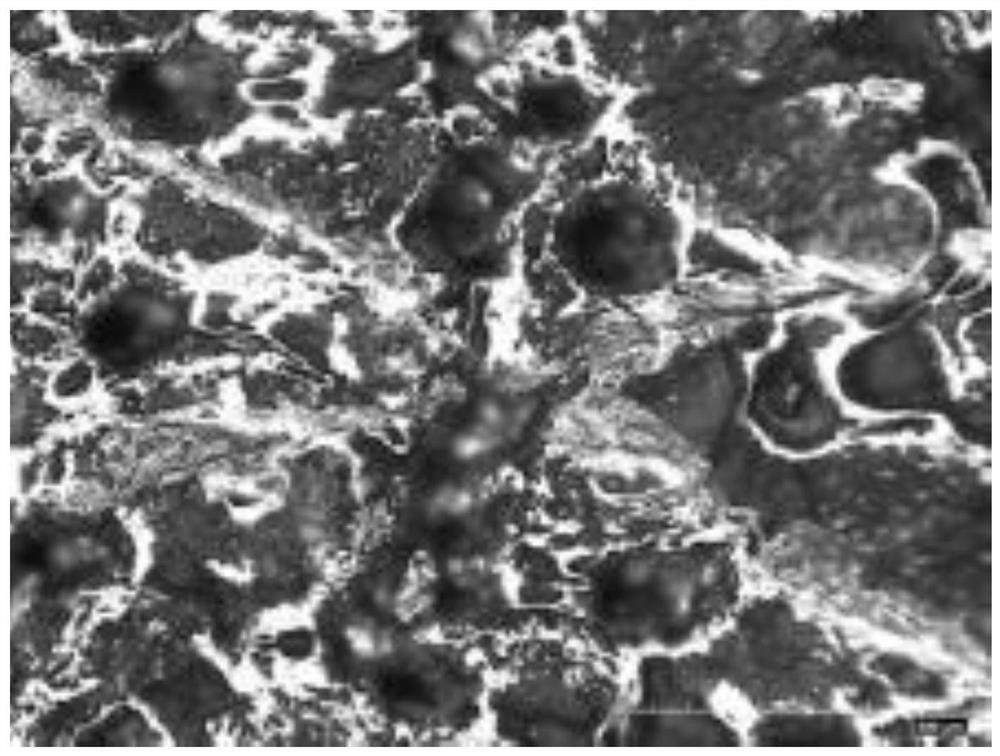

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of amphiphilic nanocellulose is:

[0064] a. Preparation of diblock copolymers containing carboxyl and epoxy units

[0065] Weigh 4,4'-azobis(4-cyanovaleric acid), carboxyl-containing hydrophilic macromolecular RAFT reagent, glycidyl methacrylate, 1, 4-dioxane, placed in a three-necked flask equipped with a magnet, stirred and dissolved to form a mixed solution;

[0066] At room temperature, argon was first introduced into the flask containing the mixed solution for 30 minutes, and then the three-necked flask was heated to 60°C to make 4,4'-azobis(4-cyanovaleric acid), carboxyl-containing hydrophilic The macromolecular RAFT reagent and glycidyl methacrylate were reacted under argon protection for 6h to obtain the product;

[0067] After the product is purified by precipitation in n-hexane, it is dried in a vacuum oven to obtain a diblock copolymer containing carboxyl and epoxy units;

[0068] b. Preparation of anionic UV-responsive block copoly...

Embodiment 1

[0075] A preparation method of an aqueous light-responsive self-healing leather finishing agent, which is specifically implemented according to the following steps:

[0076] Step 1. Preparation of mixed monomer and initiator aqueous solution

[0077] Step 1.1, weigh butyl methacrylate, methyl methacrylate, hexafluorobutyl acrylate and 7-(6-(acryloyloxyhexyloxy)- 4-methylcoumarin; mixed monomer is obtained after mixing uniformly;

[0078] Step 1.2, weigh ammonium persulfate and deionized water at a mass ratio of 1:20, respectively, obtain an aqueous initiator solution after mixing, and take out 1 / 3 of the total mass of the aqueous initiator solution for subsequent use;

[0079] Wherein, the mass of the initiator is 0.8% of the mass of the mixed monomer;

[0080] Step 2. Preparation of amphiphilic nanocellulose dispersion

[0081] Step 2.1. Weigh the amphiphilic nanocellulose powder and the aqueous sodium bicarbonate solution at a mass ratio of 2:4000;

[0082] Step 2.2, tak...

Embodiment 2

[0092]A preparation method of a water-based light-responsive self-repairing leather finishing agent, specifically implemented according to the following steps:

[0093] Step 1, preparation of mixed monomer and initiator aqueous solution

[0094] Step 1.1, Weigh butyl acrylate, methyl methacrylate, hexafluorobutyl methacrylate and 7-(2-methacryloyloxy)-4- Methyl coumarin; after mixing evenly, a mixed monomer is obtained;

[0095] Step 1.2, weigh potassium persulfate and deionized water respectively according to the mass ratio of 1:50, mix uniformly to obtain the initiator aqueous solution, take out 1 / 3 of the total mass of the initiator aqueous solution, and set aside;

[0096] Wherein, the quality of initiator is 1% of mixed monomer quality;

[0097] Step 2, preparation of amphiphilic nanocellulose dispersion

[0098] Step 2.1, weighing the amphiphilic nanocellulose powder and sodium hydroxide aqueous solution respectively according to the mass ratio of 4:3400;

[0099] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com