Synthesis method for preparing high-cost-performance lithium iron phosphate precursor by controlling crystallization

A lithium iron phosphate and crystallization control technology, which is applied in the direction of phosphorus compounds, chemical instruments and methods, structural parts, etc., can solve the problems of difficult industrialization and high requirements for the control of production conditions of lithium iron phosphate, and achieve high batch stability and synthesis The method is simple and fast, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

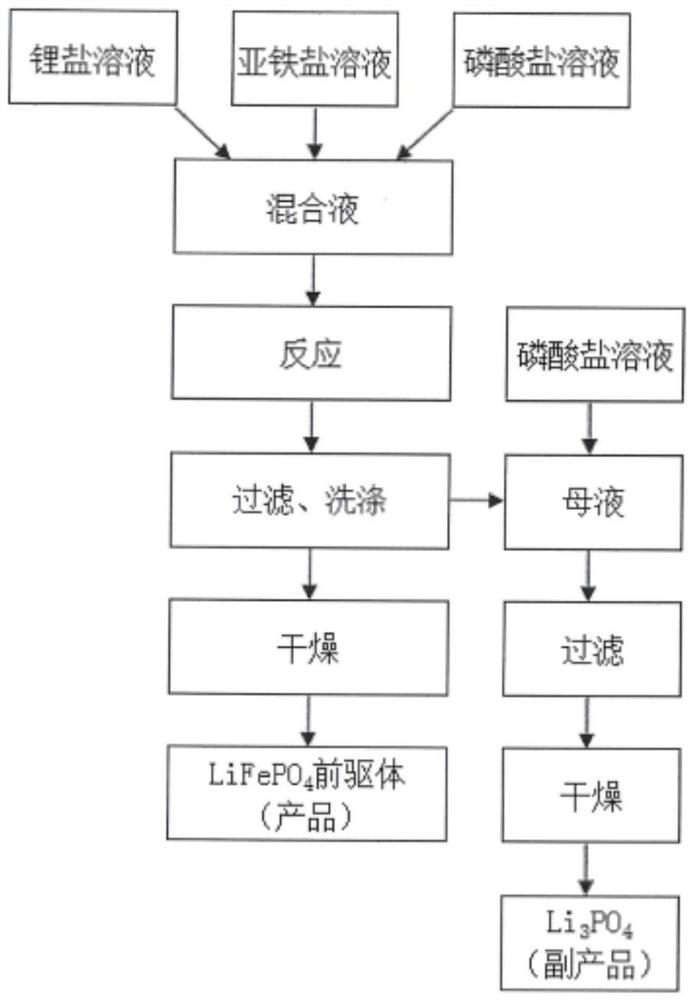

[0027] The present invention discloses a synthesis method for preparing a cost-effective lithium iron phosphate precursor by controlling crystallization. In this embodiment, lithium sulfate, ferrous sulfate, and monoammonium phosphate are used as raw materials, and sulfuric acid and sodium hydroxide are used as the pH adjustment method. Acid and base preparation of lithium iron phosphate precursor, see figure 1 , its specific preparation method is as follows:

[0028] S1) preparing lithium ion concentration with deionized water is 300L of lithium sulfate solution of 0.9mol / L, and sulfuric acid adjusts the pH value to be less than 4; It is 300L of ferrous sulfate solution of 0.3mol / L to prepare ferrous ion concentration with deionized water, and sulfuric acid to adjust the pH value to be less than 4; prepare 300L of monoammonium phosphate solution with a phosphate ion concentration of 0.3mol / L with deionized water, and adjust the pH value to be less than 4 with sulfuric acid; ...

Embodiment 2

[0034] In this example, lithium iron phosphate precursors were prepared using lithium chloride, ferrous chloride, and sodium phosphate as raw materials, and hydrochloric acid and ammonia water as acids and bases to adjust the pH value. The specific preparation method is as follows:

[0035] S1) preparing lithium ion concentration with deionized water is 300L of lithium chloride solution of 3mol / L, and hydrochloric acid regulates pH value to be less than 4; It is 300L of ferrous chloride solution of 3mol / L to prepare ferrous ion concentration with deionized water, and hydrochloric acid to adjust the pH value to be less than 4; prepare 300L of sodium phosphate solution with a phosphate ion concentration of 3mol / L with deionized water, and adjust the pH value to be less than 4 with hydrochloric acid;

[0036] In a 1000L reaction kettle, sequentially add lithium salt solution, ferrous salt solution, and phosphate solution, stir and mix evenly to obtain a mixed solution;

[0037] S...

Embodiment 3

[0041] In this example, lithium nitrate, ferrous nitrate, and sodium phosphate were used as raw materials, and nitric acid and sodium hydroxide were used as acids and bases to adjust the pH value to prepare lithium iron phosphate precursors. The specific preparation method is as follows:

[0042]S1) prepare 300L of lithium nitrate solutions with a concentration of lithium ions of 3mol / L with deionized water, and adjust the pH value with nitric acid to be less than 4; Adjust the pH value to be less than 4; prepare 300L of sodium phosphate solution with a phosphate ion concentration of 2mol / L with deionized water, and adjust the pH value to be less than 4 with nitric acid;

[0043] In a 1000L reaction kettle, sequentially add lithium salt solution, ferrous salt solution, and phosphate solution, stir and mix evenly to obtain a mixed solution;

[0044] S2) Slowly add sodium hydroxide to the reaction kettle until the pH value is 6.5, heat to 120° C., keep the reaction kettle sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com