Steel lining polyethylene pipe manufacturing processing machine and processing method

A technology for polyethylene pipes and processing machinery, which is applied in the direction of manufacturing tools, metal processing equipment, and machine tools suitable for grinding workpiece edges, etc. It can solve the problems of slowing down cleaning efficiency, slowing down production efficiency, wasting manpower, etc., and achieves improvement Effects of cleaning efficiency, slowing down production efficiency, and increasing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

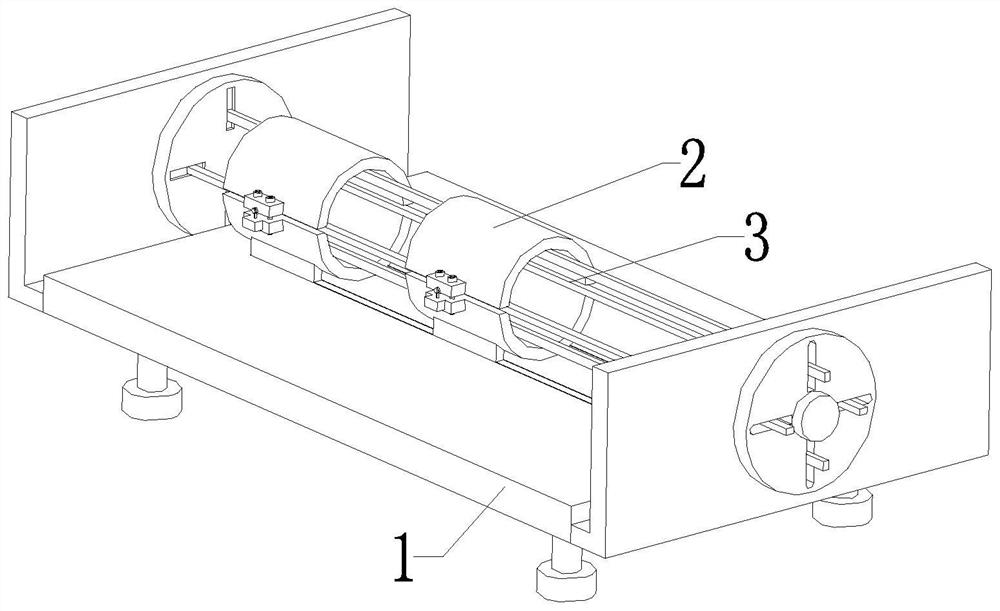

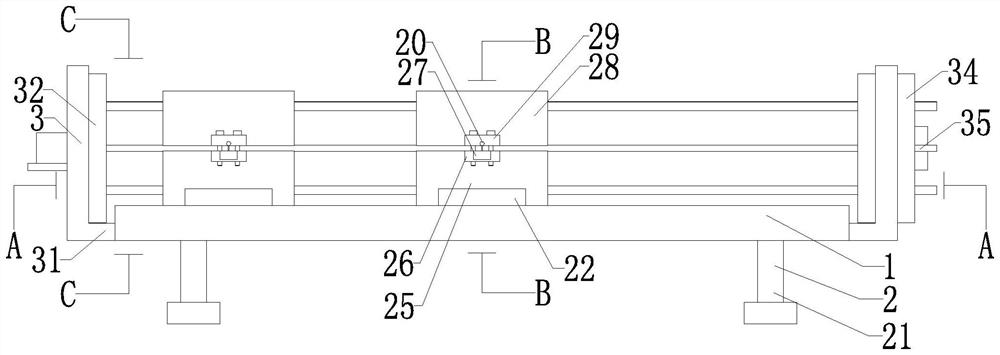

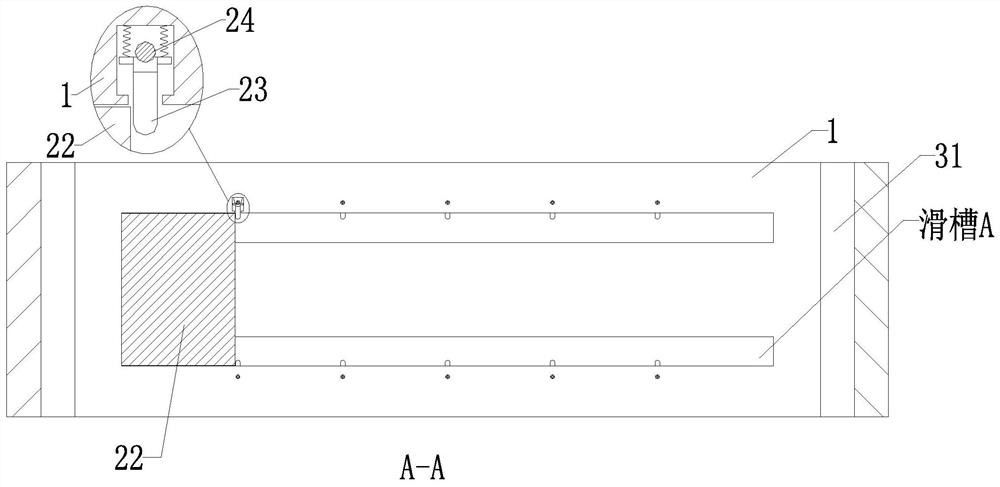

[0029] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 7 , the present invention will be further elaborated.

[0030] A steel-lined polyethylene pipe manufacturing and processing machine, comprising an installation substrate 1, a fixing kit 2 and a grinding kit 3, the mounting substrate 1 is provided with a fixing kit 2, and the outer side of the fixing kit 2 is provided with a polishing kit 3, wherein:

[0031]The fixing kit 2 includes a support rod 21 , a sliding carriage 22 , a clamping block 23 , a locking bolt 24 , a material supporting arc plate 25 , a connecting block 26 , a winding box 27 , a cover material arc plate 28 , and a closing lock block 29 And the rope rod 20, the support rod 21 is evenly mounted on the lower end surface of the installation base plate 1 by welding, the installation base plate 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com