High-purity Cu3Pt nanoparticles and preparation method thereof

A nanoparticle, high-purity technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of particle size reduction, environmental damage, time-consuming, etc., to increase the concentration of chloride ions, Environmental friendliness, effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a high-purity Cu 3 The preparation method of Pt nanoparticles is characterized in that, comprising:

[0037] S1: adding inorganic copper salt, NaCl and / or KCl to water, and mixing uniformly to obtain a mixed solution 1;

[0038] Wherein, the inorganic copper salt is a water-soluble copper salt; it can choose CuCl 2 , Cu(NO 3 ) 2 、CuSO 4 、CuCH 3 (COO) 2 One or more of, but not limited to. Preferably, the inorganic copper salt is selected from CuCl 2 , which can cooperate well with NaCl and KCl to avoid the occurrence of CuO and Cu in the reaction process 2 O and other impurities.

[0039]Specifically, in the mixed solution 1, the molar concentration of the inorganic copper salt is 10-50 mmol / L, exemplarily 10 mmol / L, 15 mmol / L, 20 mmol / L, 30 mmol / L, 40 mmol / L, 45 mmol / L, but Not limited to this. Preferably, the molar concentration of the inorganic copper salt is 10-20 mmol / L.

[0040] Among them, NaCl and KCl can provide Cl - , during ...

Embodiment 1

[0056] This embodiment provides a high-purity Cu 3 The preparation method of Pt nanoparticles is as follows:

[0057] (1) With deionized water as solvent, CuSO 4 As the solute, configure 37.5mL of a solution with a concentration of 40mmol / L, then add 0.564g NaCl, stir evenly, and obtain a mixed solution 1;

[0058] (2) Add 12.5 mL of ascorbic acid with a concentration of 1.8 mol / L to the mixed solution 1, place it in a constant temperature water bath at 95° C. for 50 minutes, and stir during the heating process to obtain the mixed solution 2;

[0059] (3) Add 6.25mL of K with a concentration of 15mmol / L to the mixed solution 2 2 PtCl 6 solution, and then reacted at 90°C for 6h to obtain a mixed solution 3;

[0060] (4) Centrifuge the mixed solution 3, disperse the obtained product in deionized water for ultrasonication and centrifuge, then disperse in ethanol for ultrasonication, centrifuge again, and then dry at 40°C to obtain the product.

Embodiment 2

[0062] This embodiment provides a high-purity Cu 3 The preparation method of Pt nanoparticles is as follows:

[0063] (1) With deionized water as solvent, CuCl 2 As the solute, configure 37.5mL of a solution with a concentration of 15mmol / L, then add 0.101g of KCl, stir evenly, and obtain a mixed solution 1;

[0064] (2) Add 12.5 mL of ascorbic acid with a concentration of 1 mol / L to the mixed solution 1, place it in a constant temperature water bath at 98° C. for 10 minutes, and stir during the heating process to obtain the mixed solution 2;

[0065] (3) Add 5mL of 10mmol / L H to the mixed solution 2 14 Cl 6 o 6 Pt solution, and then reacted at 98°C for 2h to obtain a mixed solution 3;

[0066] (4) Centrifuge the mixed solution 3, disperse the obtained product in deionized water for ultrasonication and centrifuge, then disperse in ethanol for ultrasonication, centrifuge again, and then dry at 40°C to obtain the product.

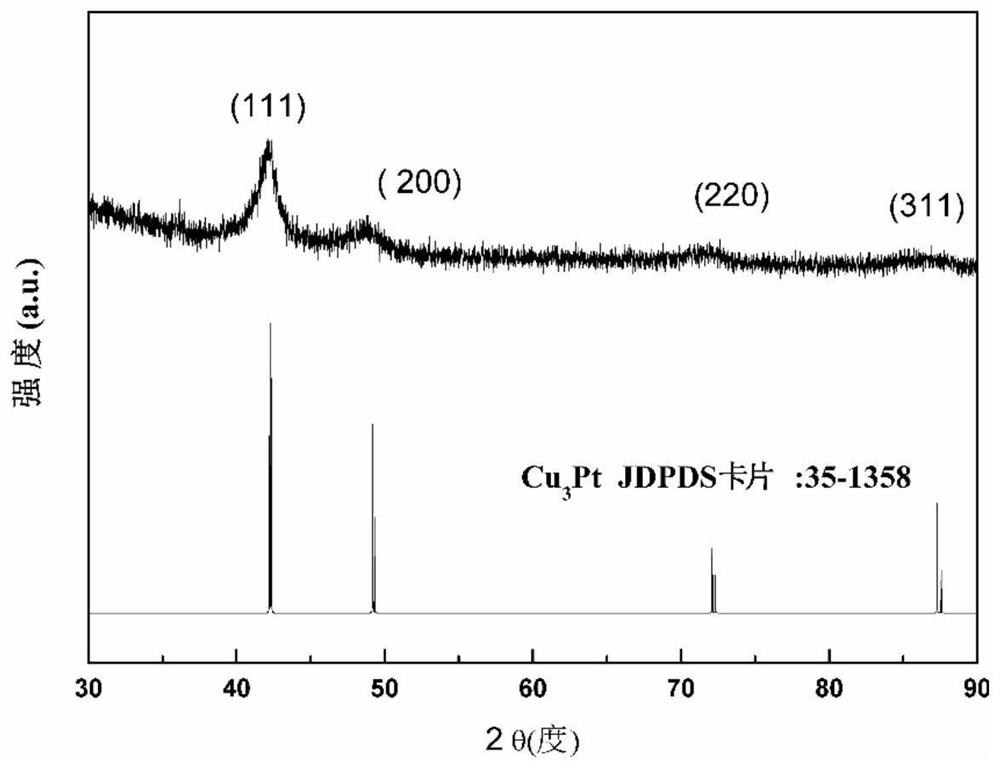

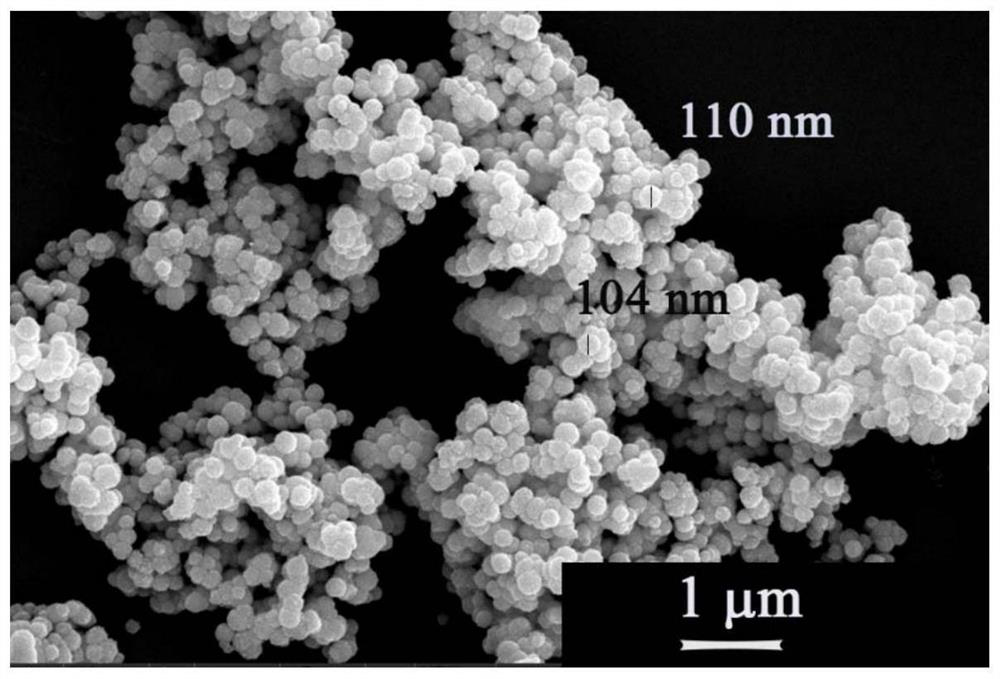

[0067] The obtained sample is carried out X-ray d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com