Treatment method of sodium trichloropyridinol high-salt wastewater

A technology for sodium clopyridinate and high-salt wastewater, which is applied in water/sewage treatment, natural water treatment, biological water/sewage treatment, etc. It can solve the problems of high chroma of wastewater and large residual amount of sodium alkoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment illustrates the overall process flow, and the process flow of a kind of clopyridinol sodium high-salt wastewater treatment method of the present invention is as follows:

[0030] Conditioning pool collection steps

[0031] This process is for harmless treatment of high-salt mixed sodium alkoxide wastewater (referred to as wastewater), and the wastewater is first transported into the regulating pool. The temperature of the regulating pool is 30-35° C., and the pH value is 7.0-8.0. The regulating pool plays the role of collecting and storing wastewater. In this embodiment, the volume of the regulating pool is 100 L.

[0032] ABR processing steps

[0033] The wastewater enters the ABR pool through the lift pump, where the hydrolytic acidification reaction is carried out, and the macromolecular organic matter is degraded into small molecular substances, and some pollutants are removed. In this embodiment, there are six ABR pools, each ABR pool has a...

Embodiment 2

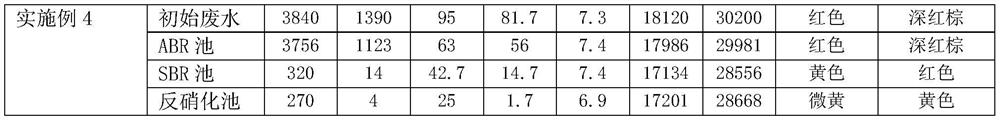

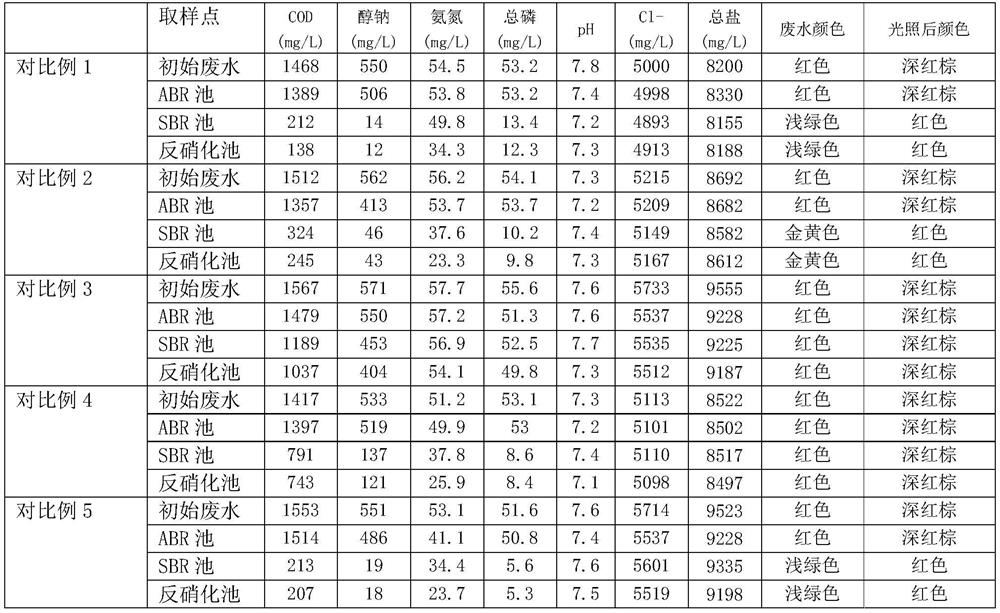

[0043] Embodiment 2-Example 4 is to carry out wastewater treatment according to the technological process of embodiment 1, specifically as follows: In the adjustment pool collection step, maintain the temperature of the adjustment pool between 30-35 ° C, and the pH value between 7.0-8.0 ; In the ABR treatment step, 7kg activated carbon particles (4 orders) and 4L EMO composite bacterial solution (4 × 10 6 each / ml), and maintain the water temperature in the ABR pool between 25-35 ° C, and the pH value between 6-9; in the SBR treatment step, 8L of EMO composite bacterial solution (4×10 6 / ml) and 13kg of activated carbon powder (50 mesh), and maintain the water temperature in the SBR pool between 25-35 °C, and the pH value between 6-9; 5kg activated carbon granules (4 mesh) and 3L EMO composite bacteria liquid (4×10 6 / ml), and maintain the denitrification tank water temperature between 25-35 ° C, pH value between 6-9; in the coagulation sedimentation treatment step, the coagul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com