Modified dental implant and preparation method thereof

A technology for dental implants and implants, applied in dentistry, chemical instruments and methods, dental implants, etc., can solve the problems of insufficient strength of titanium substrates, implant failures, poor osseointegration, etc., to improve the strength and bone integrity. The ability to combine, improve the success rate of planting, and promote the effect of mutual penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

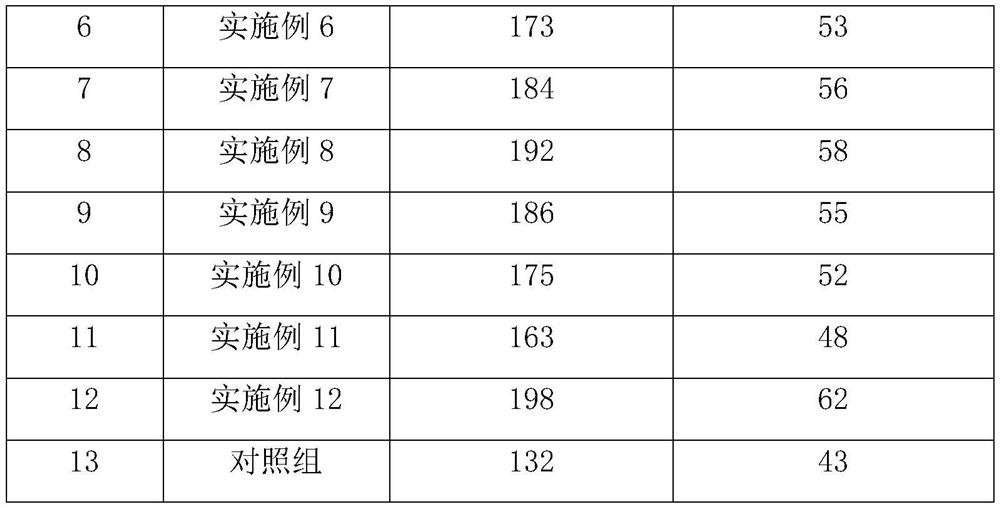

Examples

preparation example Construction

[0043] The embodiment of the present invention also provides a method for preparing the modified dental implant as described above, comprising the following steps:

[0044] 1) Print the implant base material through a 3D printer and set aside;

[0045] 2) Mixing the modified graphene and nano-titanium oxide, adding a dispersant, drying and ball milling to obtain the modified graphene-nano-titanium oxide composite coating;

[0046] 3) Evenly spin-spray the modified graphene-nano-titanium oxide composite coating on the surface of the implant base material, and after it is naturally dried, the modified dental implant is obtained;

[0047] 4) The modified dental implant is placed in a muffle furnace for calcining, then cooled, cleaned and dried to obtain a finished implant.

[0048] In the embodiment of the present invention, the mass ratio of modified graphene to nano-titanium oxide in the step 2) is (1-5):7.

[0049] In the embodiment of the present invention, the calcination ...

Embodiment 1

[0052] Take graphene oxide and bombard its surface with plasma, the plasma treatment power is 120W, and the treatment time is 20min; the graphene oxide bombarded by plasma is added to the rutin aqueous solution, and the concentration of graphene oxide and rutin aqueous solution The mass ratio is 0.5:10, disperse evenly, and let stand; filter the mixed solution, take the filter residue and vacuum-dry to obtain modified graphene; mix titanium oxide, basalt fiber and silicone oil in a mass ratio of 3:1:6 and stir evenly , transferred to an autoclave, and treated at 180°C for 3 hours to obtain a mixed slurry; the mixed slurry was dried for 2 hours at a drying temperature of 220°C to obtain a mixed dry material; the mixed dry material was ultrasonicated at a power of 800W Treat for 30 minutes, and then ball mill for 6 hours to obtain nano-titanium oxide; choose medical titanium alloy, print the implant base material by 3D printer, and set aside; mix modified graphene and nano-titani...

Embodiment 2

[0054] Take graphene oxide and bombard its surface with plasma, the plasma treatment power is 120W, and the treatment time is 20min; the graphene oxide bombarded by plasma is added to the rutin aqueous solution, and the concentration of graphene oxide and rutin aqueous solution The mass ratio is 0.5:10, disperse evenly, and let stand; filter the mixed solution, take the filter residue and vacuum-dry to obtain modified graphene; mix titanium oxide, basalt fiber and silicone oil in a mass ratio of 3:1:6 and stir evenly , transferred to an autoclave, and treated at 180°C for 3 hours to obtain a mixed slurry; the mixed slurry was dried for 2 hours at a drying temperature of 220°C to obtain a mixed dry material; the mixed dry material was ultrasonicated at a power of 800W Treat for 30 minutes, and then ball mill for 6 hours to obtain nano-titanium oxide; choose medical titanium alloy, print the implant base material by 3D printer, and set aside; mix modified graphene and nano-titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com