Shock-absorbing rubber and plastic foam material for soles, and preparation process thereof

A rubber-plastic foam material and a technology for preparation process, applied in the field of polymer materials, can solve problems such as poor shock absorption effect, and achieve the effects of good shock absorption effect, improved shock absorption performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

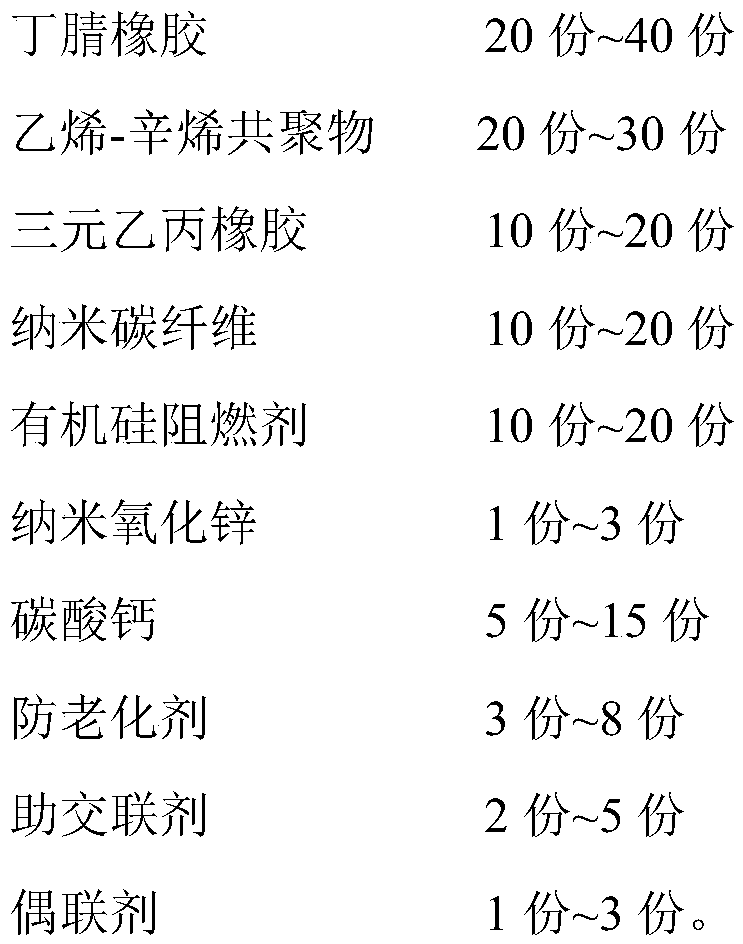

[0029] A shock-absorbing rubber and plastic foam material for shoe soles, comprising the following raw materials in parts by weight:

[0030]

[0031] In this embodiment, the antiaging agent is octylated diphenylamine.

[0032] Wherein, the co-crosslinking agent is triallyl isocyanurate.

[0033] Wherein, the coupling agent is a silane coupling agent.

[0034] The preparation technology of the shock-absorbing rubber-plastic foam material that above-mentioned a kind of sole is used, it comprises the following steps:

[0035] Step 1. High-speed mixing: Add the nitrile rubber, ethylene-octene copolymer, EPDM rubber and nano-carbon fiber into the high-speed mixer, and mix at 65°C for 10 minutes to obtain the rubber compound;

[0036] Step 2, internal mixing: put the rubber obtained in step 1 into the internal mixer, then add the organic silicon flame retardant, nano-zinc oxide, calcium carbonate and anti-aging agent in the formula, and then mix at 120°C for 10 minutes, get b...

Embodiment 2

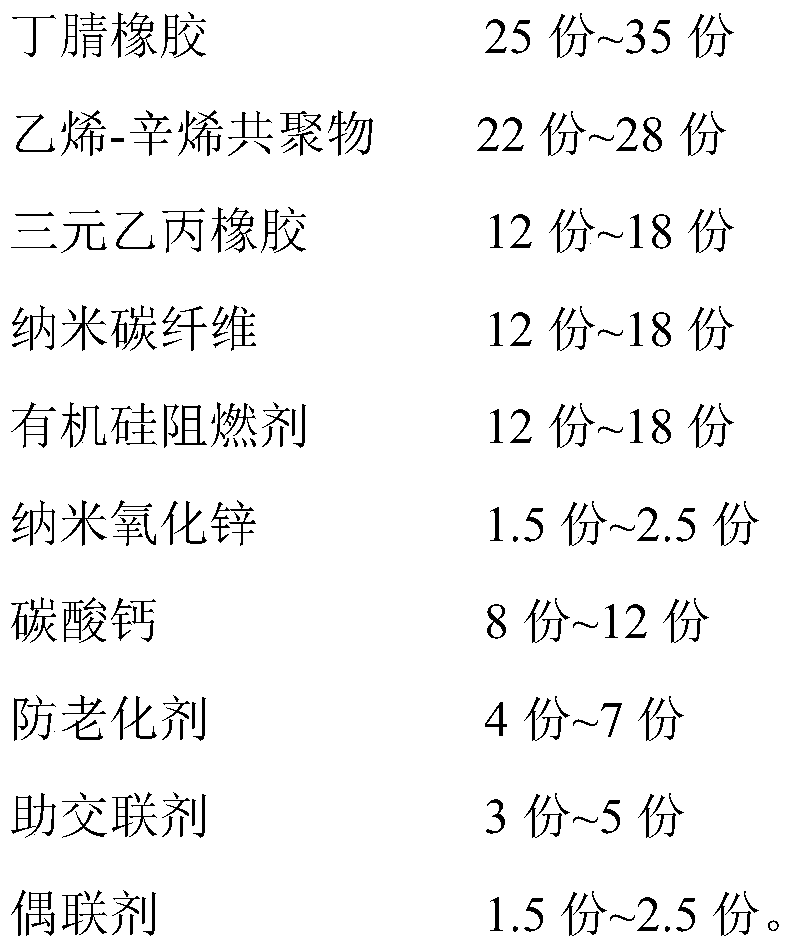

[0039] A shock-absorbing rubber and plastic foam material for shoe soles, comprising the following raw materials in parts by weight:

[0040]

[0041]

[0042] In this embodiment, the anti-aging agent is 2-mercaptobenzimidazole.

[0043] Wherein, the co-crosslinking agent is triallyl isocyanurate.

[0044] Wherein, the coupling agent is a silane coupling agent.

[0045] The preparation technology of the shock-absorbing rubber-plastic foam material that above-mentioned a kind of sole is used, it comprises the following steps:

[0046] Step 1. High-speed mixing: Add the nitrile rubber, ethylene-octene copolymer, EPDM rubber and nano-carbon fiber into the high-speed mixer, and mix at 60°C for 15 minutes to obtain the rubber compound;

[0047] Step 2, internal mixing: put the rubber obtained in step 1 into the internal mixer, then add the organic silicon flame retardant, nano-zinc oxide, calcium carbonate and anti-aging agent in the formula, and then mix at 110°C for 15 mi...

Embodiment 3

[0050] A shock-absorbing rubber and plastic foam material for shoe soles, comprising the following raw materials in parts by weight:

[0051]

[0052]

[0053] In this embodiment, the anti-aging agent is a combination of octylated diphenylamine and 2-mercaptobenzimidazole.

[0054] Wherein, the co-crosslinking agent is triallyl isocyanurate.

[0055] Wherein, the coupling agent is a silane coupling agent.

[0056] The preparation technology of the shock-absorbing rubber-plastic foam material that above-mentioned a kind of sole is used, it comprises the following steps:

[0057] Step 1. High-speed mixing: Add the nitrile rubber, ethylene-octene copolymer, EPDM rubber and nano-carbon fiber into the high-speed mixer, and mix at 62°C for 13 minutes to obtain the rubber compound;

[0058] Step 2, internal mixing: put the rubber obtained in step 1 into the internal mixer, then add the organic silicon flame retardant, nano-zinc oxide, calcium carbonate and anti-aging agent in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com