Thin film transistor and manufacturing method thereof

A technology of thin film transistor and manufacturing method, applied in transistor, semiconductor/solid-state device manufacturing, semiconductor device and other directions, can solve the problem of oxide semiconductor cutting and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

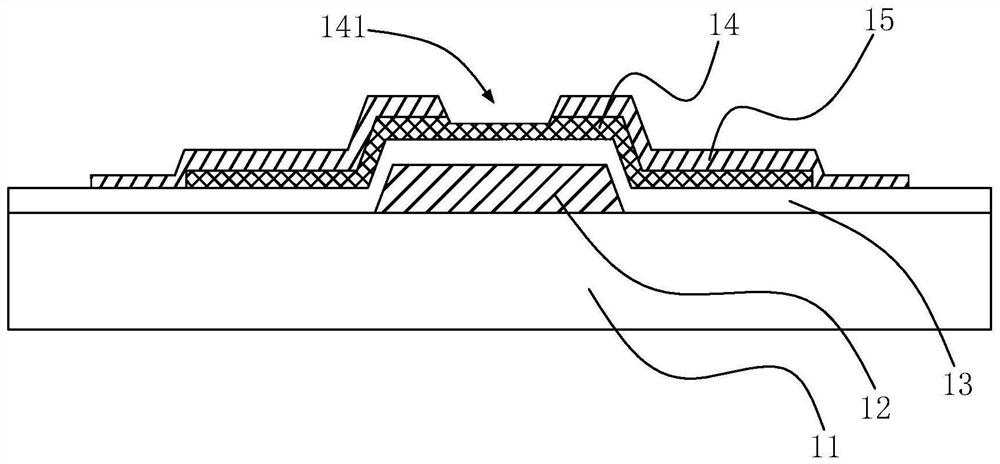

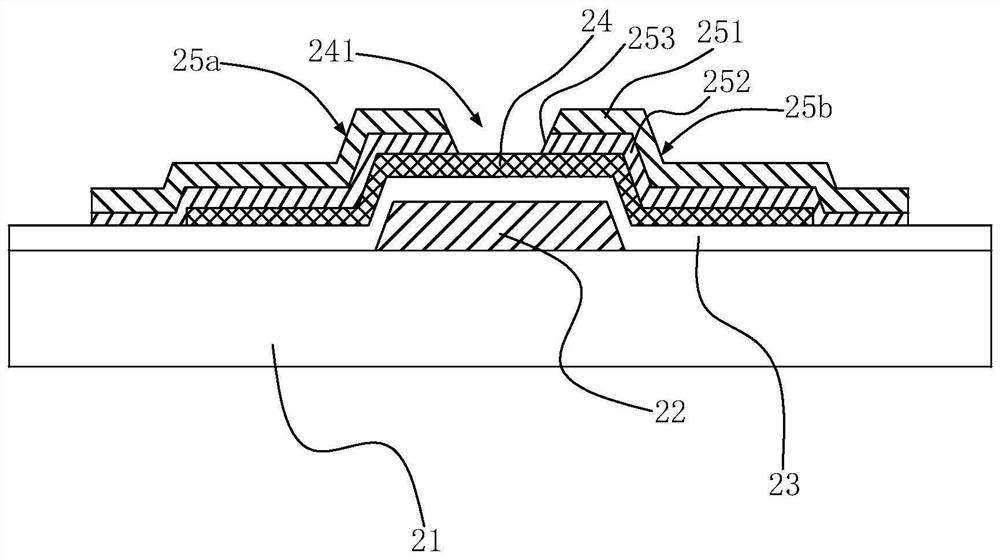

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0034] Thin Film Transistor TFT (Thin Film Transistor) is widely used in display devices, and thin film transistor technology has also developed from the original a-Si (amorphous silicon) thin film transistor to the current LTPS (low temperature polysilicon) thin film transistor, oxide (oxide) thin film Transistors, etc. Among them, thin film transistors, which are compound semiconductor active layer materials represented by metal oxides, are more popular with the public because of their advantages such as high mobility, simple manufacturing process, good uniformity in large areas, and low manufacturing costs.

[0035] The invention provides a method for manufacturing a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com