Method for preparing high-coercivity sintered neodymium-iron-boron magnet through grain boundary diffusion

A technology with high coercive force and grain boundary diffusion, applied in the direction of magnetic objects, magnetic films to substrates, magnetic materials, etc., can solve the problems of time-consuming, poor controllability of sputtering parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a high-coercivity sintered NdFeB magnet by grain boundary diffusion, specifically comprising the following steps:

[0033] (1) First use commercial degreasing powder to degrease the surface of sintered NdFeB magnets with a size of Φ10mm×5mm, then use a diluted concentration of 4vol% nitric acid solution to clean the sintered NdFeB magnets to remove rust, and finally use deionized Clean the magnet ultrasonically with water and absolute ethanol to remove impurities attached to the surface of the magnet, and dry it with a hair dryer for later use.

[0034] (2) Evacuate the vacuum chamber to the vacuum degree required for the experiment, and then fill the vacuum chamber with high-purity Ar (purity ≥ 99.999%) for ion activation sample treatment. The process of ion activation sample is to use ion source in vacuum chamber to ionize high-purity Ar into Ar + , apply a negative bias voltage on the sintered NdFeB magnet sample to attract high-energy Ar + B...

Embodiment 2

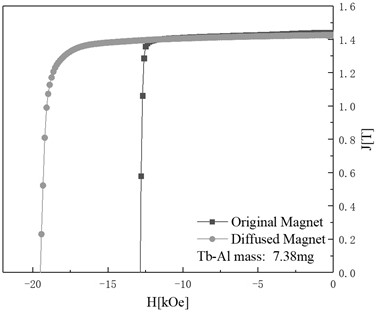

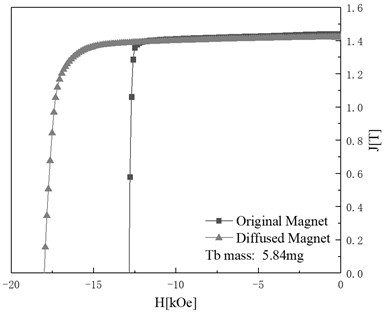

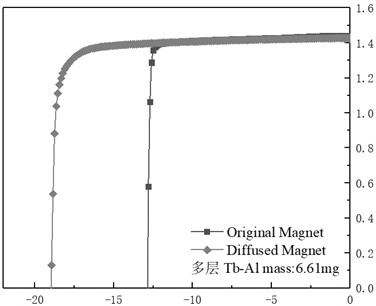

[0041] The preparation process of this embodiment is basically the same as in Example 1, the difference is that when depositing the heavy rare earth-metal multilayer film, the quality of the sputtering of each layer of the metal Al film is halved, and the number of layers remains unchanged; the diffusion magnet The demagnetization curve and the BSE-SEM image showing the diffusion depth of the film are shown in the appendix image 3 with 4 ,Depend on image 3 It can be seen that when the sputtered mass of the Al film is halved, the coercive force of the diffusion magnet decreases; Figure 4 It can be seen that the rare earth-rich shell formed after diffusion (light gray in the figure) is uniform and thin, indicating that the film diffuses deep into the magnet.

Embodiment 3

[0046] A method for preparing a high-coercivity sintered NdFeB magnet by grain boundary diffusion, specifically comprising the following steps:

[0047] (1) First use commercial degreasing powder to degrease the surface of sintered NdFeB magnets with a size of Φ10mm×5mm, then use a diluted concentration of 4vol% nitric acid solution to clean the sintered NdFeB magnets to remove rust, and finally use deionized Clean the magnet ultrasonically with water and absolute ethanol to remove impurities attached to the surface of the magnet, and dry it with a hair dryer for later use.

[0048] (2) Evacuate the vacuum chamber to the vacuum degree required for the experiment, and then fill the vacuum chamber with high-purity Ar (purity ≥ 99.999%) for ion activation sample processing. The process of ion activation sample is to use ion source in vacuum chamber to ionize high-purity Ar into Ar + , apply a negative bias voltage on the sintered NdFeB magnet sample to attract high-energy Ar + ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com