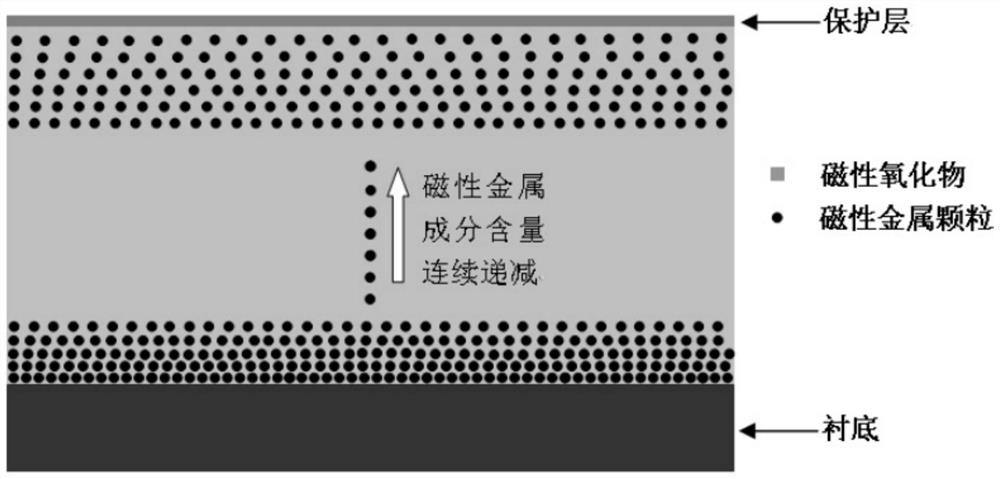

Component gradient magnetic metal-magnetic oxide particle film and preparation method thereof

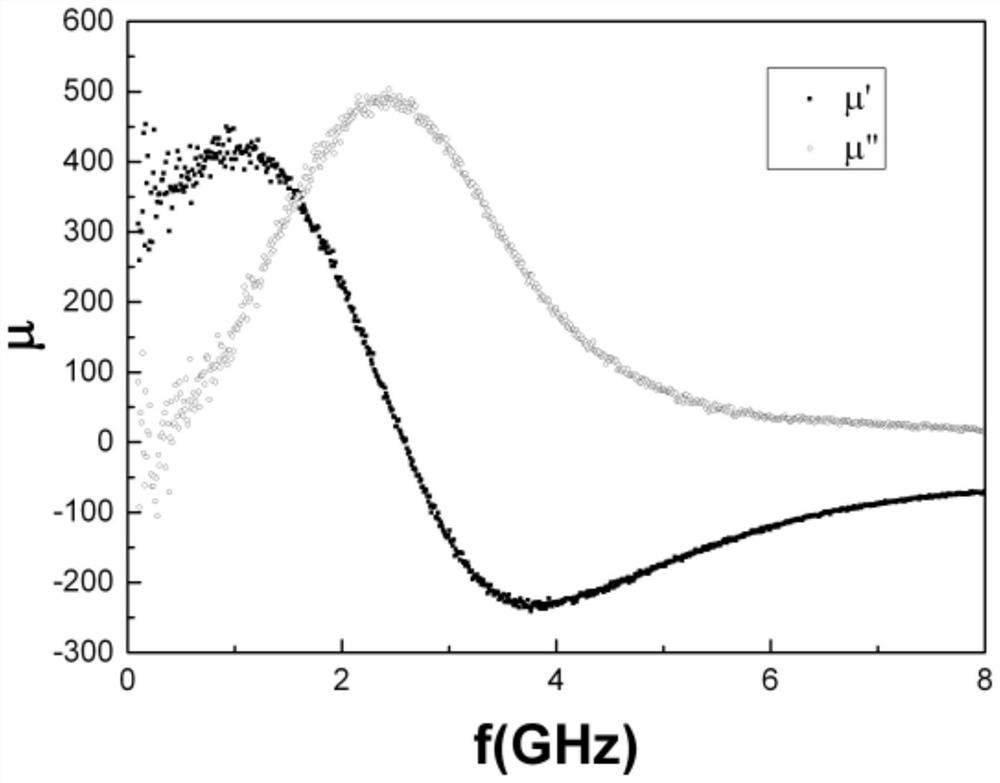

A magnetic oxide, magnetic metal technology, applied in the application of magnetic objects, magnetic films to substrates, magnetic materials, etc., can solve the problems of complex production process, reduce complex magnetic permeability, etc., to enhance the exchange coupling effect, improve Effect of saturation magnetization, high complex permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a composition gradient magnetic metal-magnetic oxide particle film:

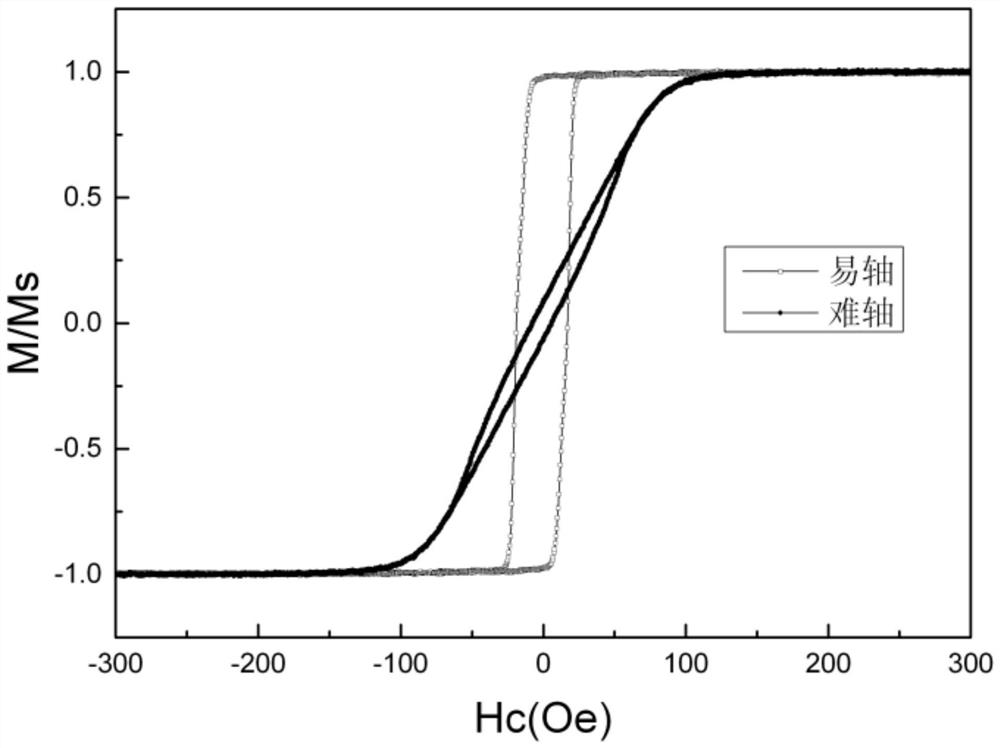

[0040] Use quartz glass as the substrate, use acetone, absolute ethanol, and deionized water to ultrasonically clean it for 15 minutes, and dry it in a vacuum oven. Observe under a microscope that there are no dust and other pollutants, and fix it on a sample holder with an induced magnetic field strength of 1000Oe. On; Fe with a purity of 99.98% 65 co 35 (The subscript on the right is the volume content ratio, and the following examples are expressed in the same way) The target material is installed on the DC magnetron target gun (A target), and the CoFe with a purity of 99.9% 2 o 4 The target is installed on the RF magnetron target gun (B target);

[0041] Two-stage vacuuming with mechanical pump and molecular pump to 5×10 -5 Pa, the sample carrier is sent into the sputtering chamber, the base distance of A target is 7cm, the base distance of B target is 13cm, the substrat...

Embodiment 2

[0048] A method for preparing a composition gradient magnetic metal-magnetic oxide particle film:

[0049] Using polyester as the substrate, the cleaning process is the same as in Example 1, and it is fixed on a sample holder with an induced magnetic field strength of 100 Oe. Fe with a purity of 99.96% 70 Si 15 B 15 The target is installed to the DC magnetron target gun (A target), and the MnFe with a purity of 99.7% 2 o 4 The target is installed on the RF magnetron target gun (B target);

[0050] Use mechanical pump and molecular pump to evacuate to 1×10 -5 Pa, the sample carrier is sent into the sputtering chamber, the target base distance is 22cm, the substrate temperature is room temperature, and the rotation rate of the sample stage is 10r / min;

[0051] Fill the sputtering chamber with argon gas with a purity of 99.999%, the flow rate is 10 sccm, and the total pressure is kept at 5 Pa;

[0052] Set the sputtering power of targets A and B to 320W and 10W respectivel...

Embodiment 3

[0056] A method for preparing a composition gradient magnetic metal-magnetic oxide particle film:

[0057] Using polyimide as the substrate, the cleaning process is the same as in Example 1, and it is fixed on a sample holder with an induced magnetic field strength of 500 Oe. A Co target with a purity of 99.99% is installed on the DC magnetron target gun (A target), and a ZnFe target with a purity of 99.7% 2 o 4 The target is installed on the RF magnetron target gun (B target);

[0058] Two-stage vacuuming with mechanical pump and ion pump to 3×10 -5 Pa, the sample carrier is sent into the sputtering chamber, the target base distance is 15cm, the substrate temperature is room temperature, and the sample stage rotation rate is 5r / min;

[0059] Fill the sputtering chamber with argon gas with a purity of 99.999%, the flow rate is 15 sccm, and the total pressure is kept at 0.2 Pa;

[0060] Set the sputtering power of targets A and B to 10W and 10W respectively, and pre-sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com