A self-powered humidity sensor based on composite spinning film and its preparation method

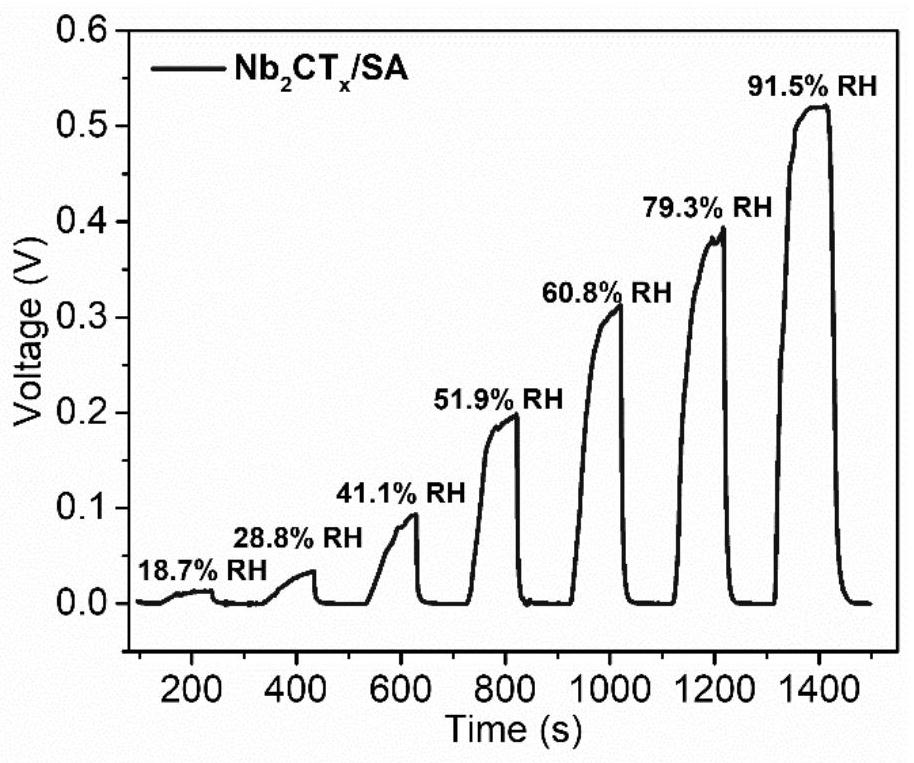

A technology of self-powered humidity and composite spinning, which is applied in the direction of generators, instruments, and scientific instruments that convert kinetic energy into electric energy, and can solve problems such as limiting sensor real-time monitoring, achieving fast response/recovery speed, simple device structure, and mass production. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

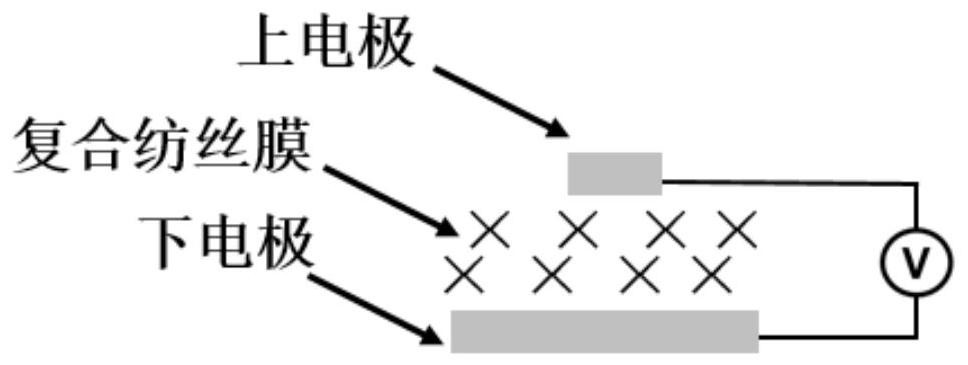

[0039] In this embodiment, PET is used as the flexible substrate, gold is used as the lower electrode material, and nickel-chromium alloy conductive tape is used as the upper electrode material.

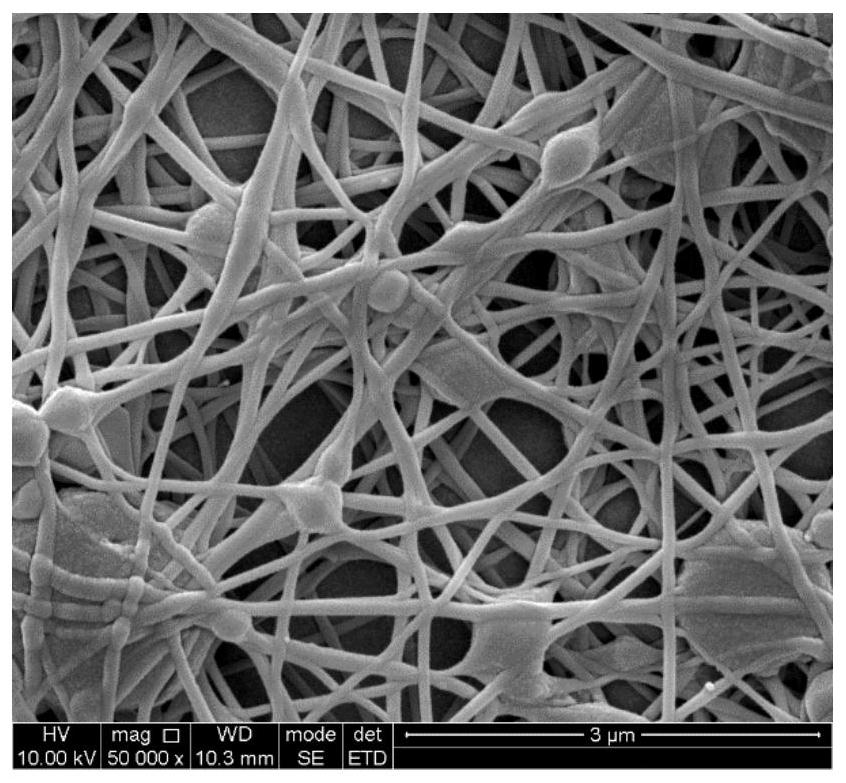

[0040] (1) Evaporate the lower electrode on a clean PET substrate by thermal evaporation process. Configure Nb 2 CT x / Sodium alginate composite spinning solution: Weigh 0.18g sodium alginate powder, 0.5g dimethyl sulfoxide, 0.1g triton, 0.02g polyethylene oxide powder, 9.2g deionized water, 20mg Nb 2 CT x Powder, stir well and set aside.

[0041] (2) Preparation of Nb 2 CT x / Sodium alginate composite spinning film: spinning height: 15cm, spinning flow rate: 10μL / min, spinning voltage: 15KV; spin on the lower electrode for 10min, then dry for later use.

[0042] (3) Soak the spinning membrane obtained in the previous step in 1 wt % calcium chloride ethanol solution for cross-linking for 5 min, dry it and set it aside.

Embodiment 2

[0045] In this embodiment, PI is selected as the flexible substrate, gold is used as the lower electrode material, and aluminum conductive tape is used as the upper electrode material.

[0046] (1) Evaporate the lower electrode on the clean PI substrate by thermal evaporation process. Configure Nb 2 CT x / Sodium alginate composite spinning solution: Weigh 0.36g sodium alginate powder, 1.0g dimethyl sulfoxide, 0.2g triton, 0.04g polyethylene oxide powder, 18.4g deionized water, 20mg Nb 2 CT x Powder, stir well and set aside.

[0047] (2) Preparation of Nb 2 CT x / Sodium alginate composite spinning film: spinning height: 20cm, spinning flow rate: 10μL / min, spinning voltage: 20KV; spin on the lower electrode for 20min, then dry for later use.

[0048] (3) Dip the spun film obtained in the previous step into 1 wt% copper acetate ethanol solution for cross-linking for 5 min, and dry it for later use.

[0049] (4) Use aluminum conductive tape to make a porous upper electrode...

Embodiment 3

[0051] In this embodiment, flexible waterproof paper is used as the flexible substrate, and conductive carbon black is used as the electrode material.

[0052] (1) A conductive carbon black electrode layer was prepared on a clean waterproof paper substrate by scraping process. Configure Nb 2 CT x / Sodium alginate composite spinning solution: Weigh 0.72g sodium alginate powder, 2.0g dimethyl sulfoxide, 0.4g triton, 0.08g polyethylene oxide powder, 36.8g deionized water, 100mg Nb 2 CT x Powder, stir well and set aside.

[0053] (2) Preparation of Nb 2 CT x / Sodium alginate composite spinning film: spinning height: 20cm, spinning flow rate: 15μL / min, spinning voltage: 15KV; spin on the lower electrode for 15min, then dry for later use.

[0054] (3) Soak the spinning membrane obtained in the previous step in 1 wt % ferric chloride ethanol solution for cross-linking for 10 min, and dry it for later use.

[0055] (4) Use the porous carbon black electrode layer as the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com