Preparation method of ZrO2@PET fiber oil-water separation material

An oil-water separation and fiber technology, applied in the field of preparation of ZrO2@PET fiber oil-water separation materials, can solve the problems of low separation efficiency, poor corrosion resistance and cannot be reused, and achieve high separation efficiency, excellent recyclability, excellent The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

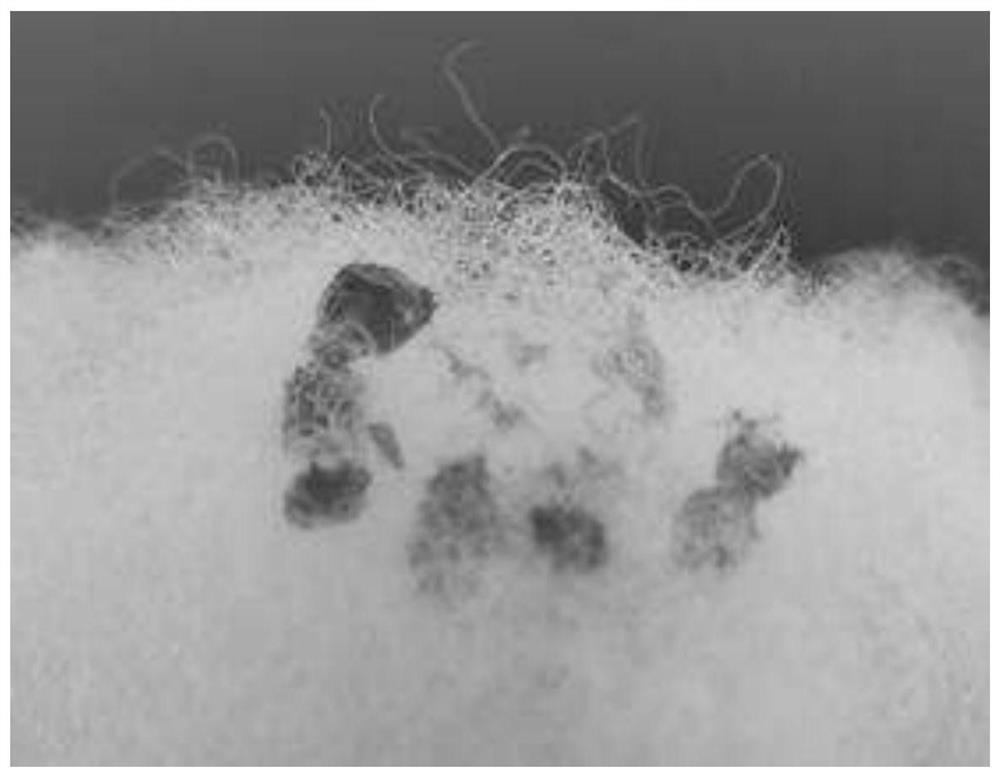

Image

Examples

Embodiment 1

[0042] Step 1, the ZrO 2 The sol is coated on the surface of the PET fiber, and the ZrO 2 PET fibers for the gel layer;

[0043] Step 1.1, prepare 0.1mol / L ZrO 2 sol

[0044] Dissolve 0.2g of acetylacetone in 20ml of absolute ethanol and stir at room temperature for 30min to obtain a mixed solution. Add 0.77g of zirconium n-butoxide to the mixed solution and continue to stir for 4h at room temperature and dropwise add 0.0726 g acetic acid, leave it to stand for aging for 12h after stirring, and obtain ZrO 2 Sol;

[0045] Step 1.2, impregnating PET fibers in ZrO 2 10s in the sol, take it out, and centrifuge at a speed of 1000r / min for 1min on a centrifuge, and dry the PET fibers after centrifugation at room temperature to obtain 2 PET fibers for the gel layer;

[0046] Among them, the PET fiber used should have a crimped and fluffy state that can provide a loose porous structure;

[0047] Step 2, with ZrO obtained in step 1 2 The PET fiber of the gel layer is placed on...

Embodiment 2

[0053] Step 1, the ZrO 2 The sol is coated on the surface of the PET fiber, and the ZrO 2 PET fibers for the gel layer;

[0054] Step 1.1, prepare 0.3mol / L ZrO 2 sol

[0055] Dissolve 0.6g of acetylacetone in 20ml of absolute ethanol and stir at room temperature for 45min to obtain a mixed solution, add 2.3g of zirconium n-butoxide to the mixed solution and continue to stir at room temperature for 5h and dropwise add 0.25 g acetic acid, left to stand and aged for more than 12h after stirring, to obtain ZrO 2 Sol;

[0056] Step 1.2, impregnating PET fibers in ZrO 2 Put in the sol for 15s, take it out, centrifuge at a speed of 1500r / min for 1min on a centrifuge, and dry the centrifuged PET fiber in an oven at 70°C to obtain ZrO 2 PET fibers for the gel layer;

[0057] Among them, the PET fiber used should have a crimped and fluffy state that can provide a loose porous structure;

[0058] Step 2, with ZrO obtained in step 1 2 The PET fiber of the gel layer is placed on a...

Embodiment 3

[0064] Step 1, the ZrO 2 The sol is coated on the surface of the PET fiber, and the ZrO 2 PET fibers for the gel layer;

[0065] Step 1.1, prepare 0.6mol / L ZrO 2 sol

[0066] Dissolve 1.2g of acetylacetone in 20ml of absolute ethanol and stir at room temperature for 60min to obtain a mixed solution. Add 4.6g of zirconium n-butoxide to the mixed solution and continue stirring at room temperature for 6h and dropwise add 0.576 g acetic acid, leave it to stand for aging for 12h after stirring, and obtain ZrO 2 Sol;

[0067] Step 1.2, impregnating PET fibers in ZrO 2 Put in the sol for 20s, take it out, centrifuge at a speed of 2000r / min for 1min on a centrifuge, and dry the centrifuged PET fibers in an oven at 100°C to obtain ZrO 2 PET fibers for the gel layer;

[0068] Among them, the PET fiber used should have a crimped and fluffy state that can provide a loose porous structure;

[0069] Step 2, with ZrO obtained in step 1 2 The PET fiber of the gel layer is placed on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com