Terminal box

A terminal box and box body technology, which is applied in the direction of non-electric variable control, instruments, guards/shutters to prevent contact with contacts, etc., can solve the problem of lack of control, lack of cooling effect, and inability to meet the operation of intelligent electronic equipment Requirements and other issues, to achieve the effect of intelligentization, easy temperature control and dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

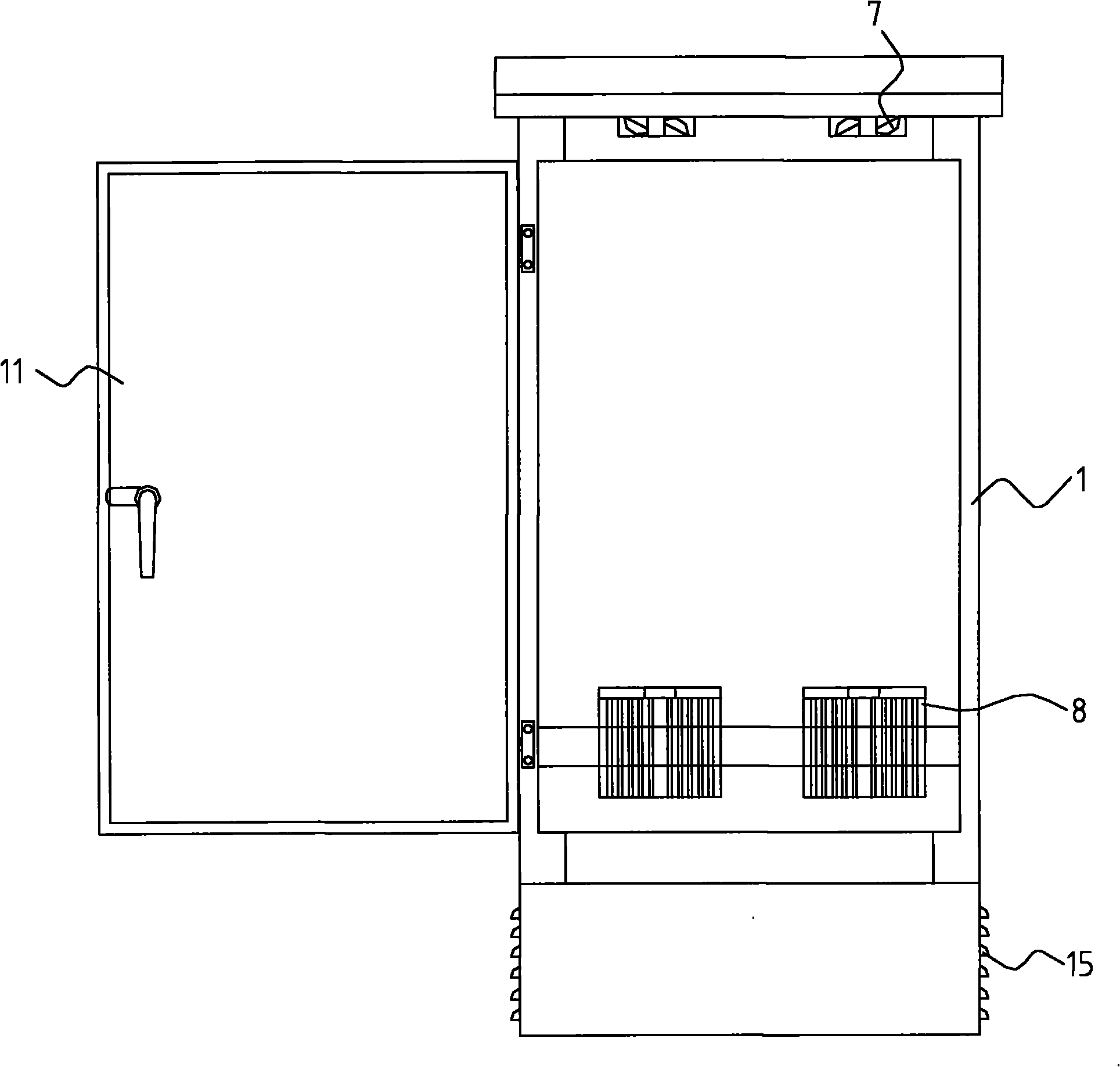

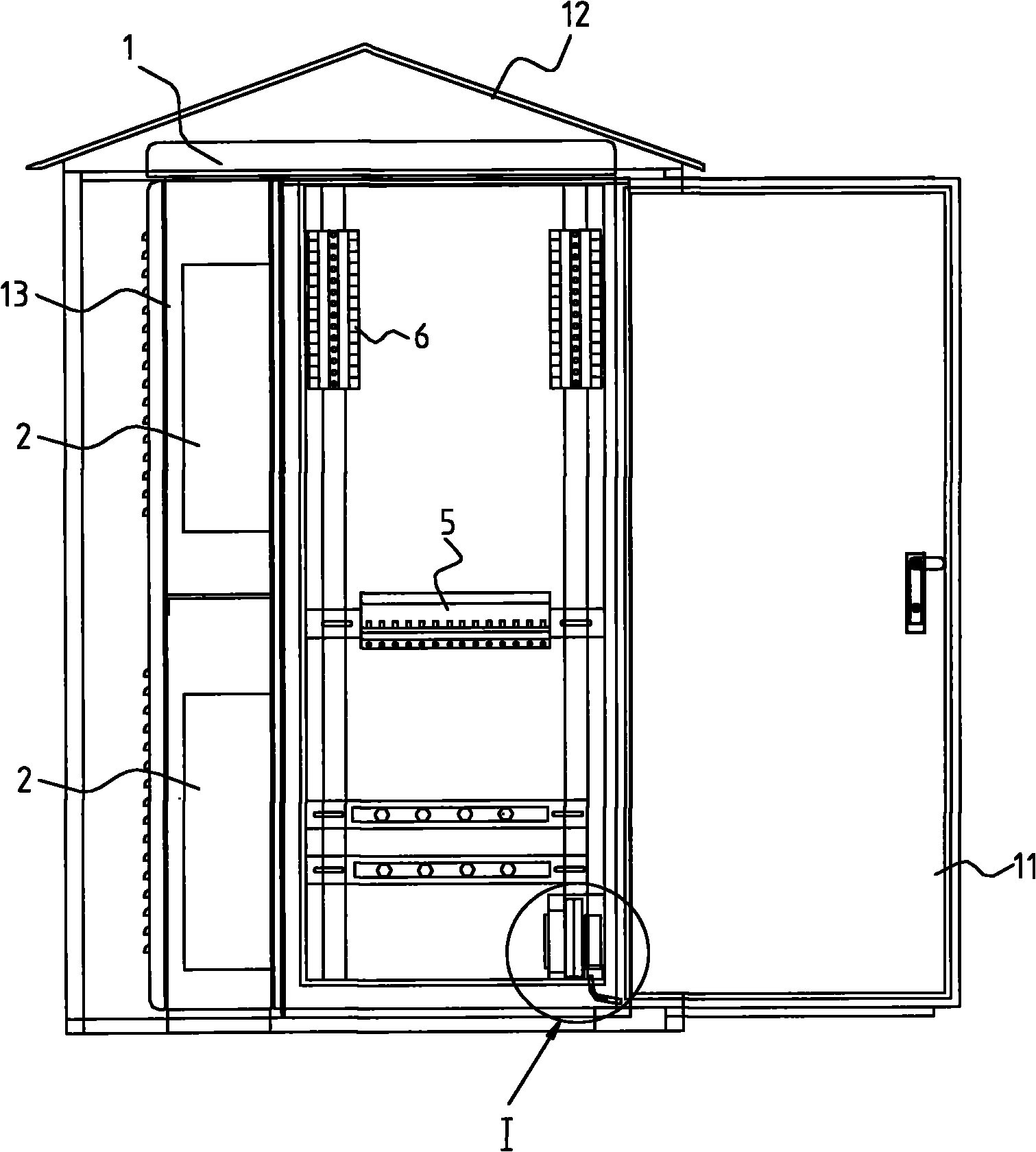

[0031] The terminal box of the present invention is mainly composed of a box body and a temperature and humidity control device for adjusting the temperature and humidity inside the box.

[0032] see Figure 2 to Figure 6 The box body is a relatively airtight structure composed of a box body body 1 and a box door 11 arranged on the front side of the box body body 1, and a terminal block 6 and an electrical component 5 are housed in the box body. Each wall of the box body 1 and the box door 11 are composed of an inner layer and an outer layer, and heat insulation cotton is filled between the inner layer and the outer layer, so that the temperature rise inside the box body can be reduced when exposed to the sun. Increase the heat insulation effect with the outside world when the temperature is adjusted. A wooden protective cover 12 is provided above the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com