Pr < 3 + >/Ho < 3 + > doped ZAlFB optical fiber glass and preparation method thereof

An optical fiber and glass technology, applied in the field of Pr3+/Ho3+ doped ZAlFB optical fiber glass and its preparation, can solve the problems of low luminous intensity, limited application, increased probability of non-radiative transition of rare earth ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

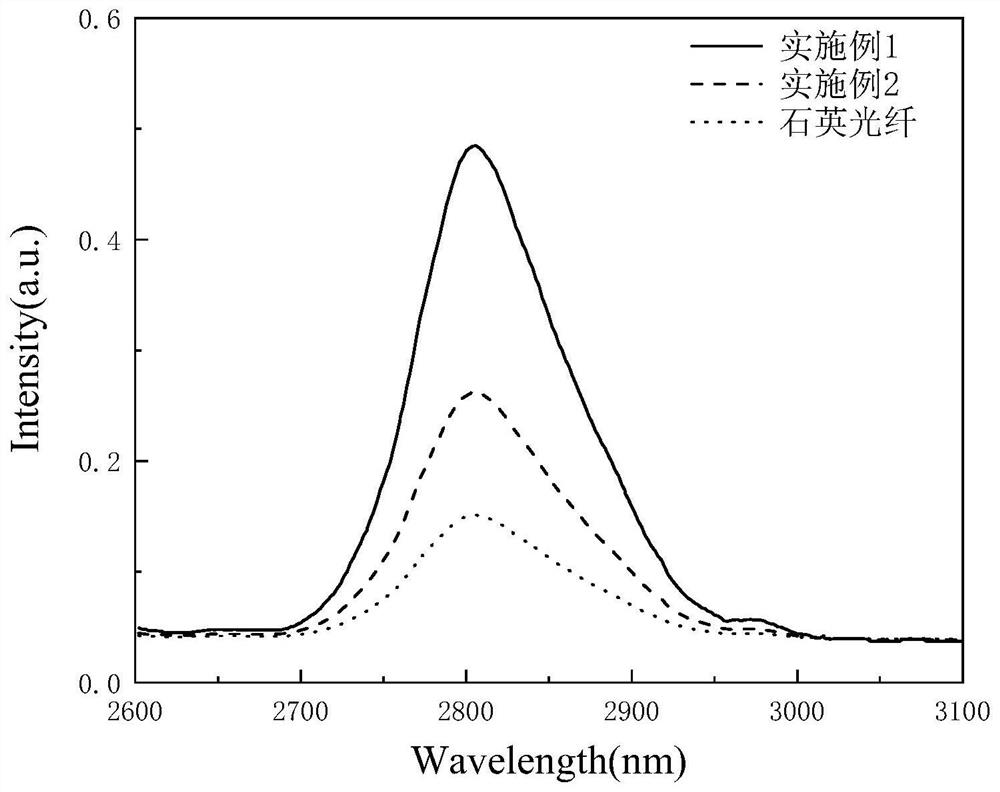

Embodiment 1

[0032] The invention provides a Pr 3+ / Ho 3+ Doped ZAlFB glass, its preparation method includes the following steps:.

[0033] (1) According to the molar percentage, take each raw material respectively: ZnF of 10mol% 2 , 4mol% Al 2 o 3 , 30mol% LiF, 55mol% B 2 o 3 , 0.5 mol% Pr 6 o 11 , 0.5mol% HoF 3 , for standby; wherein, the mass percent purity of each raw material is required to be 99.99%.

[0034] (2) Fully grind and mix the raw materials weighed in step (1) in an agate mortar, and the grinding time is 6 hours; then put them in an oven and keep them warm for 300 minutes at a temperature of 300°C; then pour them into a porcelain crucible , heated and melted in a high-temperature vacuum electric furnace, the melting temperature is 1200° C., the holding time is 180 minutes, and the vacuum degree is 0.5 MPa to obtain a glass melt.

[0035] (3) Use the vacuum suction casting method to quickly transfer the glass melt obtained in step (2) into a pre-heated stainless st...

Embodiment 2

[0039] The invention provides a Pr 3+ / Ho 3+ Doped ZAlFB glass, its preparation method includes the following steps:.

[0040] (1) According to the molar percentage, take each raw material respectively: ZnF of 10mol% 2 , 4.4mol% Al 2 o 3 , 30mol% LiF, 55mol% B 2 o 3 , 0.1mol% Pr 6 o 11 , 0.5mol% HoF 3 , for standby; wherein, the mass percent purity of each raw material is required to be 99.99%.

[0041] (2) Fully grind and mix the raw materials weighed in step (1) in an agate mortar, and the grinding time is 6 hours; then put them in an oven and keep them warm for 300 minutes at a temperature of 300°C; then pour them into a porcelain crucible , heated and melted in a high-temperature vacuum electric furnace, the melting temperature is 1200° C., the holding time is 180 minutes, and the vacuum degree is 0.5 MPa to obtain a glass melt.

[0042] (3) Use the vacuum suction casting method to quickly transfer the glass melt obtained in step (2) into a pre-heated stainless s...

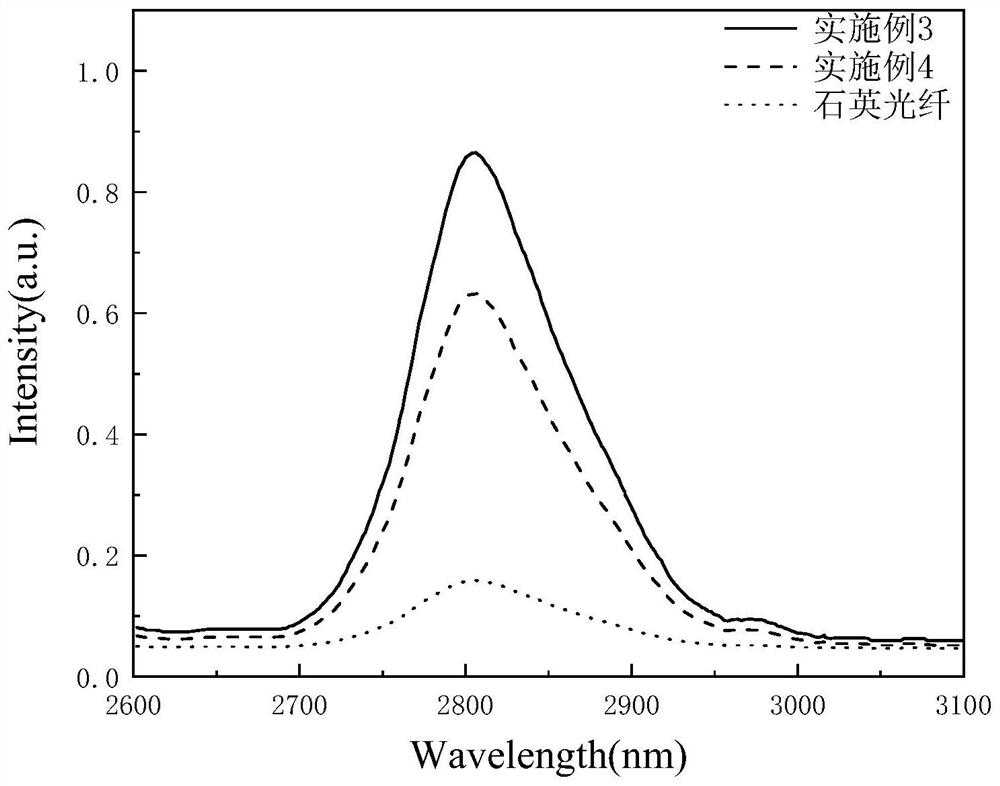

Embodiment 3

[0046] The invention provides a Pr 3+ / Ho 3+ Doped ZAlFB glass, its preparation method includes the following steps:.

[0047] (1) According to the molar percentage, take each raw material respectively: ZnF of 9mol% 2 , 5mol% Al 2 o 3 , 29mol% LiF, 56mol% B 2 o 3 , 0.4mol% Pr 6 o 11 , 0.6 mol% HoF 3 , for standby; wherein, the mass percent purity of each raw material is required to be 99.99%.

[0048] (2) Fully grind and mix the raw materials weighed in step (1) in an agate mortar, and the grinding time is 5 hours; then put them in an oven and keep them warm for 600 minutes at a temperature of 100°C; then pour them into a porcelain crucible , heated and melted in a high-temperature vacuum electric furnace with a melting temperature of 1300° C., a holding time of 120 minutes, and a vacuum degree of 0.1 MPa to obtain a glass melt.

[0049] (3) Use the vacuum suction casting method to quickly transfer the glass melt obtained in step (2) into a pre-heated stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com