Modified basalt fiber reinforced scoria lightweight aggregate concrete and preparation method thereof

A technology of light aggregate concrete and basalt fiber, applied in the field of building materials, can solve the problems of acid-base etching degree and position difficult to fix, can not guarantee the continuity of fiber reinforcement, etc., achieve excellent mechanical properties, improve performance, The effect of enhancing chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Weigh 100g of sodium hydroxide solution with a concentration of 0.5mol / L, 100g of water glass with a modulus of 3, and 10g of basalt fiber;

[0028] 2) Mix the sodium hydroxide solution and the liquid water glass solution in step 1 uniformly; add 10g of basalt fiber to the mixed solution, control the temperature at 80°C, and the treatment time for 2h; filter the solution to obtain the treated basalt fiber;

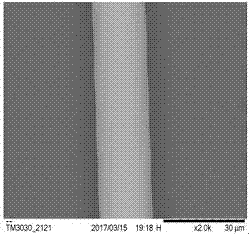

[0029] 3) Mix the basalt fiber treated in step 2 with silica fume to achieve surface wrapping, and place it in a drying oven at 105°C for 3 hours to prepare modified basalt fiber for use;

[0030] 4) Weigh 100g of cement, 17.4g of slag, 21.7g of fly ash, 13g of silica fume, 0.5g of modified basalt fiber, 55.7g of 1-3mm lava, 98.7g of 3-5mm lava, 98.7 of 5-8mm lava g, 0.6g water reducing agent, 70g water;

[0031] 5) Pour the cement, slag, silica fume, fly ash, water reducing agent and other materials weighed in step 4 into the mixing pot and stir mechanically until unifo...

Embodiment 2

[0034] 1) Weigh 100g of sodium hydroxide solution with a concentration of 1mol / L, 100g of water glass with a modulus of 3, and 10g of basalt fiber;

[0035] 2) Mix the sodium hydroxide solution and the liquid water glass solution in step 1 evenly; add 10g of basalt fiber to the mixed solution, control the temperature at 60°C, and the treatment time for 2h. Basalt fiber treated by filtering the solution;

[0036] 3) Mix the basalt fiber treated in step 2 with silica fume to achieve surface wrapping, and place it in a drying box at 105°C for drying for 3 hours to prepare modified basalt fiber for use.

[0037] 4) Weigh 100g of cement, 17.4g of slag, 21.7g of fly ash, 13g of silica fume, 0.5g of modified basalt fiber, 55.7g of 1-3mm lava, 98.7g of 3-5mm lava, 98.7 of 5-8mm lava g, 0.6g water reducing agent, 70g water;

[0038] 5) Pour the cement, slag, silica fume, fly ash, water reducing agent and other materials weighed in step 4 into the mixing pot and stir mechanically until uniform...

Embodiment 3

[0041] 1) Weigh 100g of sodium hydroxide solution with a concentration of 1mol / L, 100g of water glass with a modulus of 3, and 10g of basalt fiber;

[0042] 2) Mix the sodium hydroxide solution and the liquid water glass solution in step 1 uniformly; add 10g of basalt fiber to the mixed solution, control the temperature at 80°C, and the treatment time for 1h. Basalt fiber treated by filtering the solution;

[0043] 3) Mix the basalt fiber treated in step 2 with silica fume to achieve surface wrapping, and place it in a drying box at 105°C for drying for 3 hours to prepare modified basalt fiber for use.

[0044] 4) Weigh 100g of cement, 17.4g of slag, 21.7g of fly ash, 13g of silica fume, 0.5g of modified basalt fiber, 55.7g of 1-3mm lava, 98.7g of 3-5mm lava, 98.7 of 5-8mm lava g, 0.6g water reducing agent, 70g water;

[0045] 5) Pour the cement, slag, silica fume, fly ash, water reducing agent and other materials weighed in step 4 into the mixing pot and stir mechanically until unif...

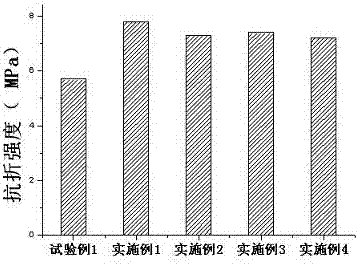

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com