Rapid cooling device for non-ferrous metal smelting rolled product production

A non-ferrous metal and cooling device technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of affecting processing and slow cooling, and achieve the effect of improving efficiency, simple operation and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

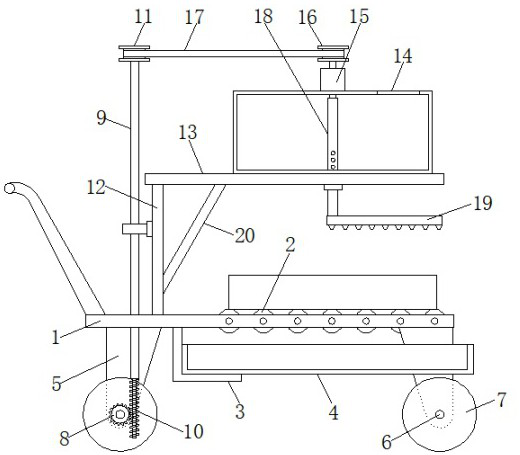

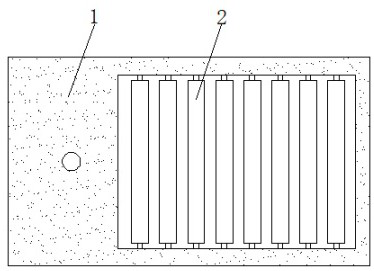

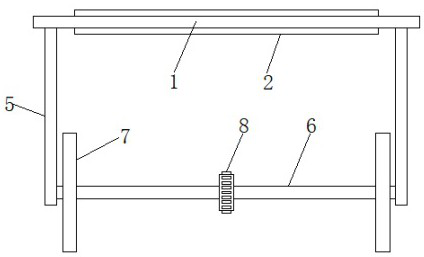

[0022] refer to Figure 1-3 , an embodiment provided by this scheme: a rapid cooling device for the production of non-ferrous metal smelting and rolling products, including a placing plate 1, a plurality of guide rollers 2 are arranged on the inner movable sleeve of the placing plate 1, and the guide rollers 2 There is a water receiving tank 4 fixedly connected to the bottom of the placing plate 1 below, a moving mechanism is provided on both sides of the bottom of the placing plate 1, a gear 8 is fixedly connected to the moving mechanism on the left side, and a fixed plate is fixedly connected to the top of the placing plate 1 12. The left side of the fixed plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com