Metal organic framework/halide composite ammonia adsorbent and preparation method thereof

A metal-organic framework, halide technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of low ammonia adsorption, poor heat and mass transfer capabilities, etc., to improve ammonia absorption performance, alleviate Adsorption hysteresis, excellent and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

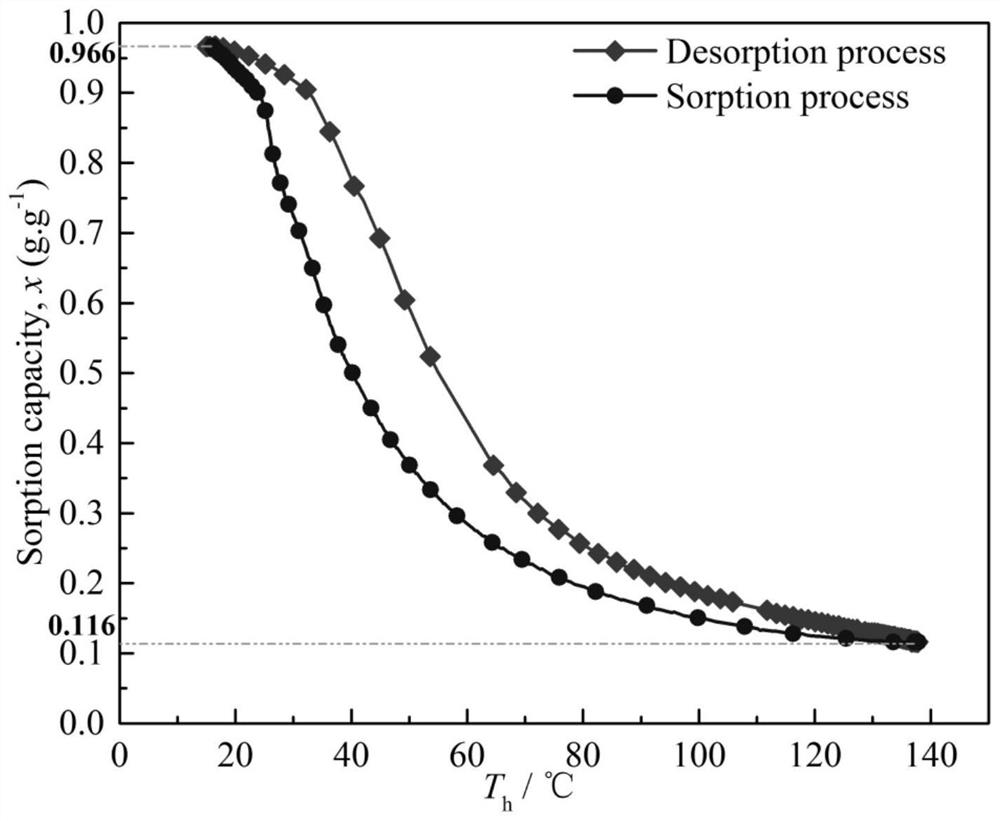

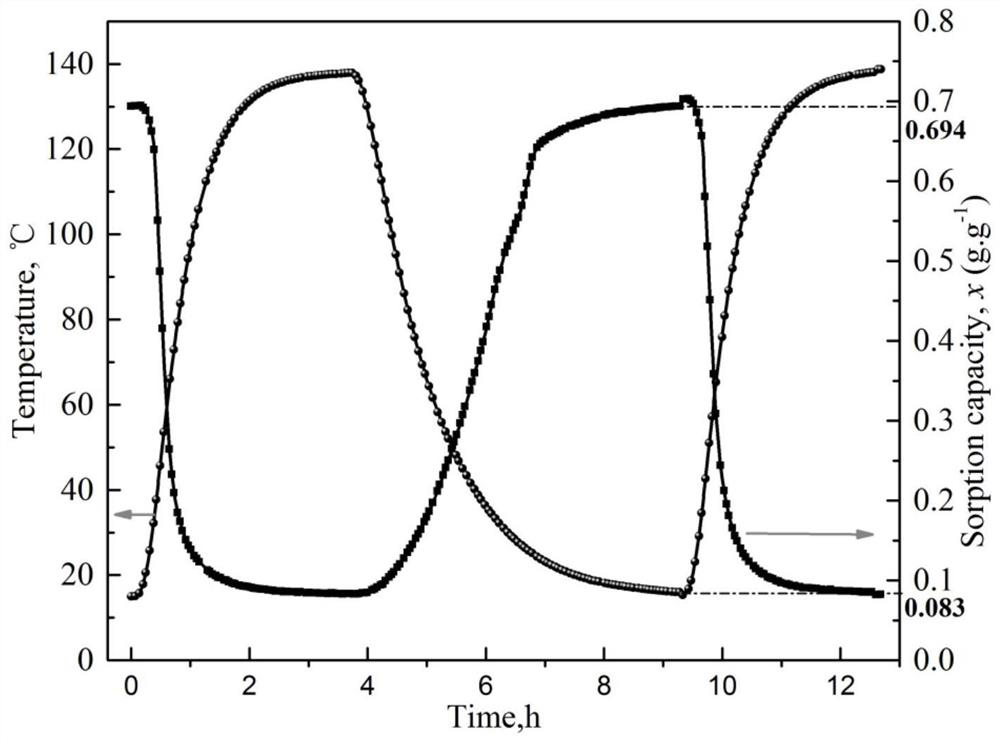

[0040] Example 1 Performance testing of different metal organic frameworks and halides alone as ammonia adsorbents

[0041] 1) The present embodiment provides a kind of preparation method of MIL-101 (Cr) ammonia adsorbent, the steps are as follows:

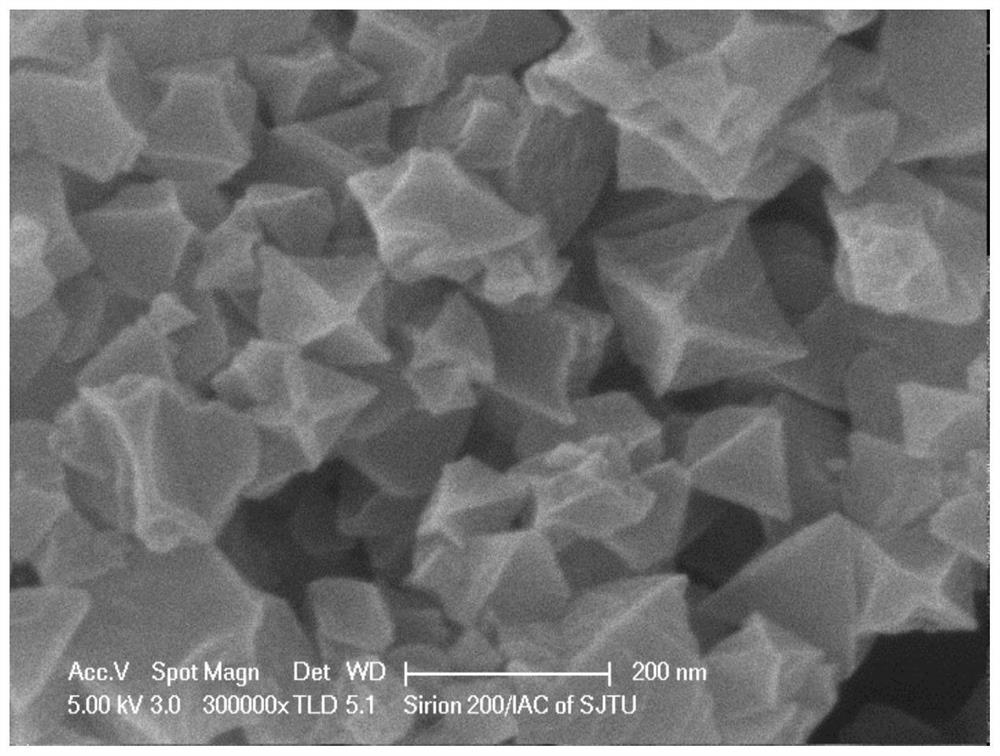

[0042] Add 10mmol Cr(NO 3 ) 3 9H 2 O and 10 mmol H 2 BDC. Then 0.58ml of glacial acetic acid was added. After sonicating for 30 min at room temperature, the mixture was transferred to an autoclave and heated at a temperature of 220 °C for 8 h. After cooling to room temperature, the green solid was successively washed with deionized water, DMF and ethanol. Finally, the obtained solid was vacuum-dried at 150° C. for 12 h to obtain MIL-101 (Cr) ammonia adsorbent.

[0043]2) The present embodiment provides a kind of preparation method of ZIF-8(Zn) ammonia adsorbent, the steps are as follows:

[0044] 16.53 mmol of Hmim was dissolved in 50 mL of methanol to obtain solution A1. In addition, 4.13mmol Zn(NO 3 ) 2 ·6H 2 O was d...

Embodiment 2

[0056] This example provides a method for preparing a metal-organic framework / halide composite ammonia adsorbent, the steps are as follows:

[0057] First weigh a certain proportion of calcium chloride (prepared by the method of step 5 of Example 1), pour into a certain amount of deionized water for dissolving respectively, and prepare a 25% calcium chloride aqueous solution for subsequent use. Then weigh a certain amount of MIL-101 (Cr) (prepared by the step 1) method of embodiment 1), the preparation concentration is 10mg / ml, and obtain well-dispersed MIL-101 (Cr) after fully processing with an ultrasonic disperser ) suspension for later use.

[0058] Next, add the prepared calcium chloride aqueous solution into the well-dispersed MIL-101(Cr) suspension to obtain a mixture of the calcium chloride solution and the MIL-101(Cr) suspension.

[0059] Again, fully stir for 12 hours by a magnetic stirrer, and completely impregnate calcium chloride into the micropores of MIL-101 (C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com