Manufacturing method of stress adjusting micron LED chip

A LED chip and stress adjustment technology, applied in the field of micro-LEDs, can solve problems such as uneven current distribution of LED chips, limited improvement effect, and immature micro-LED technology, so as to avoid surface non-radiative radiation effects and serious current uniformity , to avoid the effect of the polarization effect is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

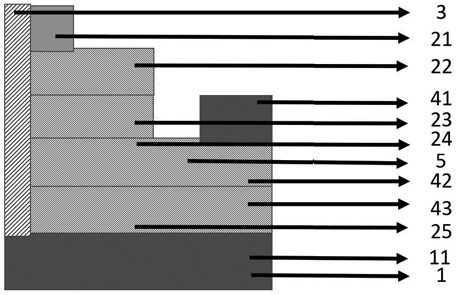

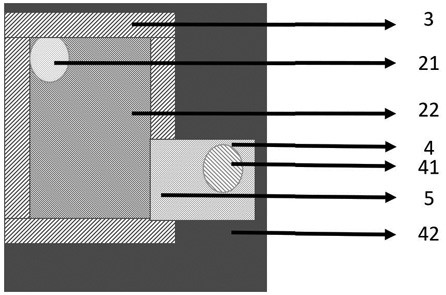

[0031] In order to better understand the purpose and function of the present invention, a method for manufacturing stress-regulated micro-LED chips of the present invention will be further described in detail below in conjunction with the accompanying drawings.

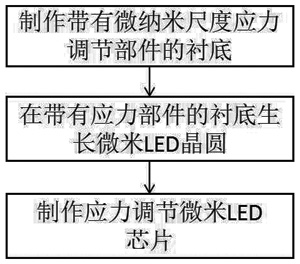

[0032] according to figure 1 , a method for manufacturing a stress-regulated micro-LED chip according to an embodiment of the present invention includes:

[0033] Step 111: Fabricate the substrate 1 with the micro-nano scale stress adjustment component 3;

[0034] Step 112: growing micro-LED wafers on the substrate with stress components;

[0035] Step 113: Fabricate stress-regulated micro-LED chips.

[0036] Furthermore, the area of the micro-nano-scale stress adjustment component 3 is less than or equal to 50000µm 2 ; The production process of the micro-nano scale stress adjustment component 3 includes:

[0037] Step 1111: Depositing a stress-adjusting material on the substrate;

[0038] Step 1112:

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com