PVK-TMDCs Van der Waals heterojunction and preparation method thereof

A heterojunction, pvk-tmdcs technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problem of fixed-point transfer technology that cannot achieve mass production, low experimental repeatability, Issues that affect the performance and application of fabricated devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

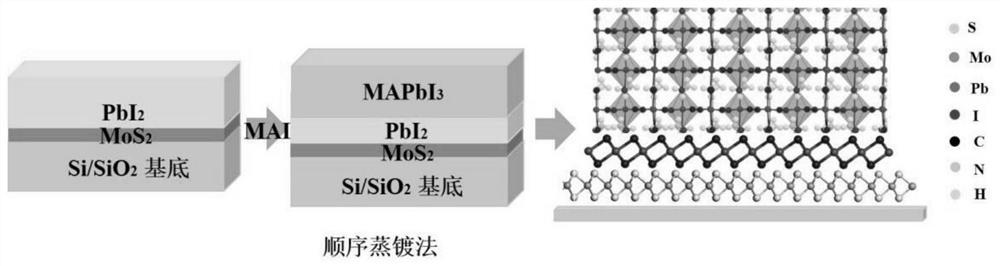

[0030] The invention provides a method for preparing a PVK-TMDCs van der Waals heterojunction, comprising the following steps:

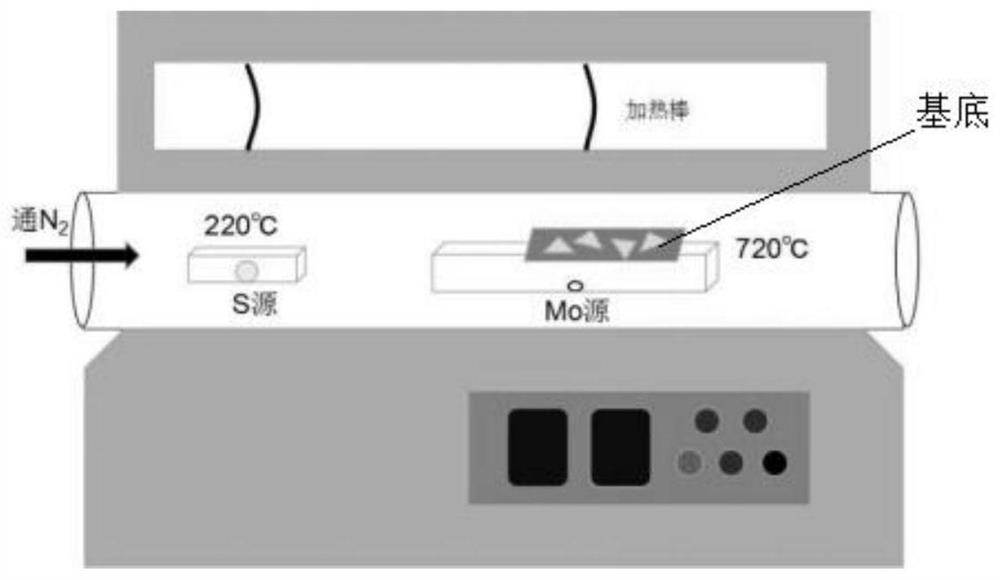

[0031] (1) Prepare a transition metal chalcogenide thin film on a substrate by chemical vapor deposition;

[0032] (2) Preparing a perovskite film on the surface of the transition metal chalcogenide film obtained in the step (1) by physical vapor deposition to obtain a PVK-TMDCs van der Waals heterojunction.

[0033] The invention adopts a chemical vapor deposition method to prepare a transition metal chalcogenide thin film on a substrate.

[0034] In the present invention, the material of the transition metal chalcogenide film is preferably MoS 2 、MoSe 2 or WS 2 , more preferably MoS 2 . The thin film prepared by the transition metal chalcogen compound in the invention has better photoelectric performance.

[0035] In the present invention, the substrate preferably includes a Si layer and SiO 2 layer; the Si layer is preferably a P-type heavi...

Embodiment 1

[0069] The substrate is Si layer and SiO 2 The composite material formed by layers, the Si layer is a P-type heavily doped Si layer, SiO 2 The thickness of the layer is 300nm; the transition metal chalcogenide is MoS 2 , the perovskite is MAPbI 3 ;

[0070] Pretreat the substrate. The pretreatment method is: cut the substrate along the crystal direction of the silicon substrate with a diamond glass knife, cut the substrate into a rectangle with a size of 3×2 cm, and first use deionized water to ultrasonically clean it for 15 minutes to remove debris on the surface of the substrate. ; Then ultrasonically clean with acetone for 15 minutes, isopropanol for 15 minutes, acetone for 15 minutes, and isopropanol for 15 minutes to remove the organic matter attached to the surface; finally, use hydrogen peroxide for 10 minutes to ultrasonically clean, and after cleaning, blow the surface of the substrate with a nitrogen gun dry to obtain a substrate with a clean surface;

[0071] Th...

Embodiment 2

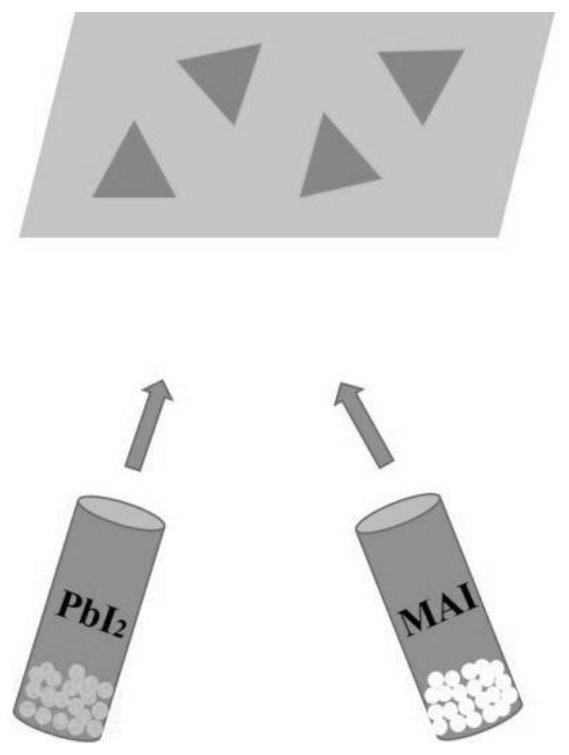

[0077] In the preparation method of Example 2, step (1), step (2) and step (3) are exactly the same as Example 1, the difference is that step (4) adopts co-evaporation method to deposit MAPbI 3 film;

[0078] (4) Deposition of MAPbI by co-evaporation 3 film, coated with a single layer of MoS with adhesive tape 2 The substrate is glued to the manipulator and then installed in the furnace. After the assembly is completed, the vacuum is started, and the mechanical pump is first turned on to pump the cavity to 10 -1 mbar, then turn on the molecular pump to pump the cavity to 10 -7 mbar; PbI 2 Raise to 340°C at a rate of 2°C / min, and raise MAI to 91°C at a rate of 0.5°C / min, and then use a robot to coat a single layer of MoS 2 The substrate is extended into the cavity, and the surface of the substrate is also facing down, and it is deposited for 3 minutes. 2 , and then open the cavity to take out the substrate to get MoS 2 -MAPbI 3 Heterojunction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com