Rapid environment-friendly double-sided polishing method for silicon wafer substrate

A green, environmentally friendly, double-sided polishing technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low polishing process time cost, difficulty in conforming to epitaxy process, and inconsistency with development concepts, and shorten processing time. , fast polishing, consistent surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

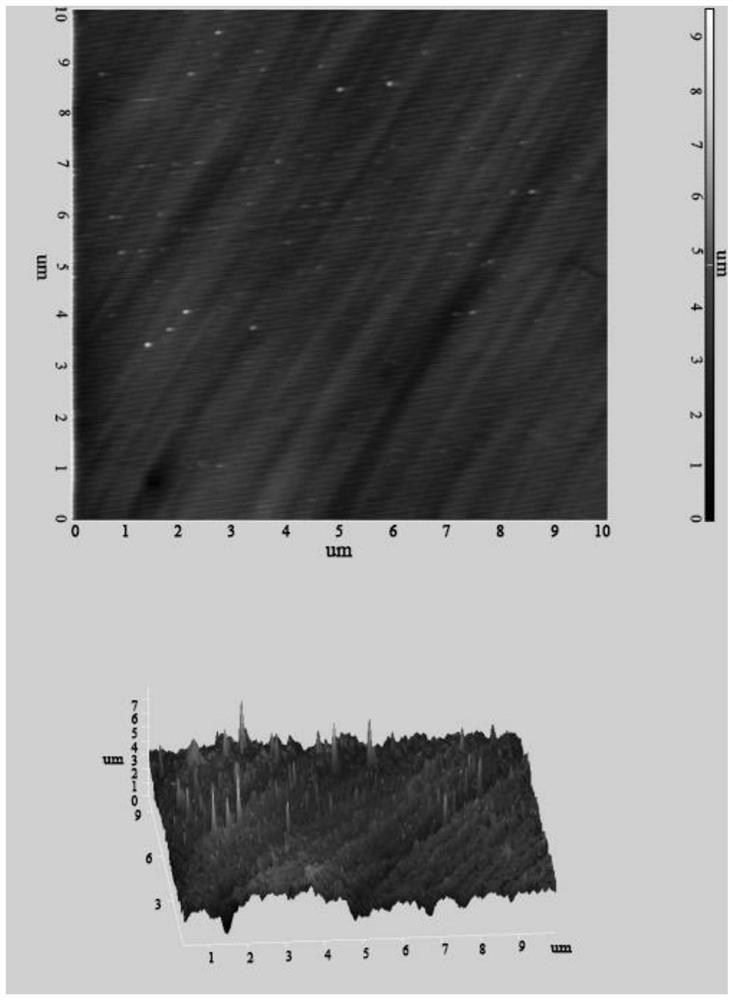

Embodiment 1

[0027] A kind of fast green environmental protection double-side polishing method of silicon wafer substrate, comprises the following steps:

[0028] (1) Loading: Take five 4-inch silicon wafer substrates and place them in the star wheel;

[0029] (2) Rough polishing: the silicon wafer substrate is chemically mechanically polished with a rough polishing solution, and after polishing, it is ultrasonically cleaned with deionized water and ethanol for 10 min, and dried; the rough polishing solution is composed of cerium oxide, deionized water, Prepared from dispersant and pH adjusting agent;

[0030] (3) Fine polishing: the silicon wafer substrate is chemically mechanically polished with a fine polishing solution after rough polishing, ultrasonically cleaned with deionized water and ethanol for 10 minutes respectively after polishing, and dried; the fine polishing solution is composed of cerium oxide, deionized Prepared with ionized water and dispersant.

[0031] In the present...

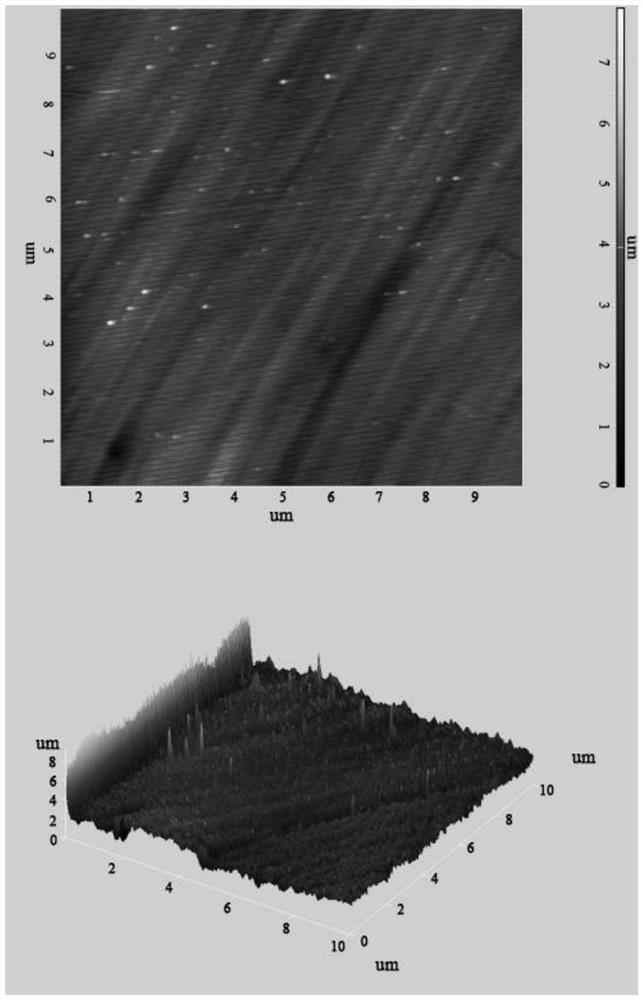

Embodiment 2

[0035] A kind of fast green environmental protection double-side polishing method of silicon wafer substrate, comprises the following steps:

[0036] (1) Loading: Take five 4-inch silicon wafer substrates and place them in the star wheel;

[0037] (2) Rough polishing: the silicon wafer substrate is chemically mechanically polished with a rough polishing solution, and after polishing, it is ultrasonically cleaned with deionized water and ethanol for 10 min, and dried; the rough polishing solution is composed of cerium oxide, deionized water, Prepared from dispersant and pH adjusting agent;

[0038] (3) Fine polishing: the silicon wafer substrate is chemically mechanically polished with a fine polishing solution after rough polishing, ultrasonically cleaned with deionized water and ethanol for 10 minutes respectively after polishing, and dried; the fine polishing solution is composed of cerium oxide, deionized Prepared with ionized water and dispersant.

[0039] In the present...

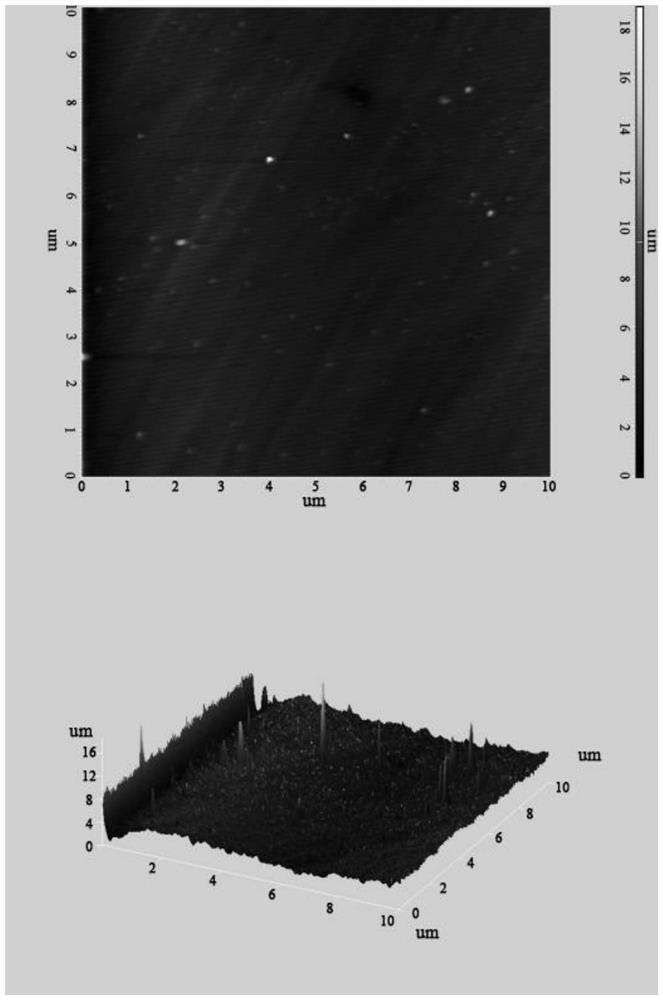

Embodiment 3

[0043] A kind of fast green environmental protection double-side polishing method of silicon wafer substrate, comprises the following steps:

[0044] (1) Loading: Take five 4-inch silicon wafer substrates and place them in the star wheel;

[0045] (2) Rough polishing: the silicon wafer substrate is chemically mechanically polished with a rough polishing solution, and after polishing, it is ultrasonically cleaned with deionized water and ethanol for 10 min, and dried; the rough polishing solution is composed of cerium oxide, deionized water, Prepared from dispersant and pH adjusting agent;

[0046](3) Fine polishing: the silicon wafer substrate is chemically mechanically polished with a fine polishing solution after rough polishing, ultrasonically cleaned with deionized water and ethanol for 10 minutes respectively after polishing, and dried; the fine polishing solution is composed of cerium oxide, deionized Prepared with ionized water and dispersant.

[0047] In the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com