Low-slump water reducing agent and preparation method thereof

A water reducing agent and slump technology, applied in the field of materials, can solve the problems of not achieving the ideal effect and the sensitivity of joint usage, etc., to achieve improved steric resistance and electrostatic repulsion, excellent water reducing rate, and excellent slump The effect of maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

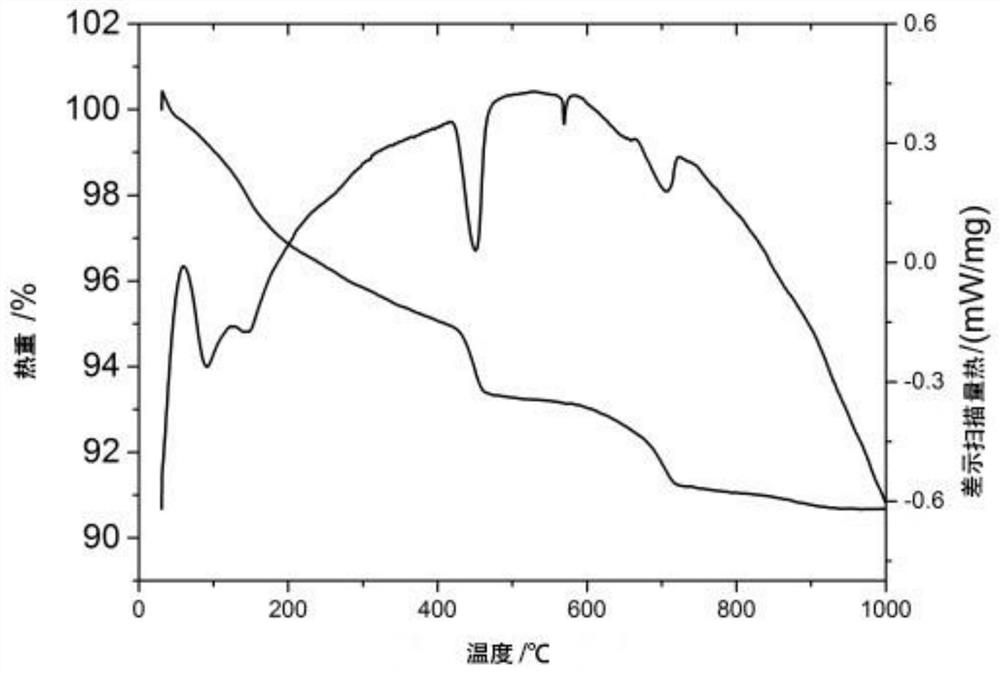

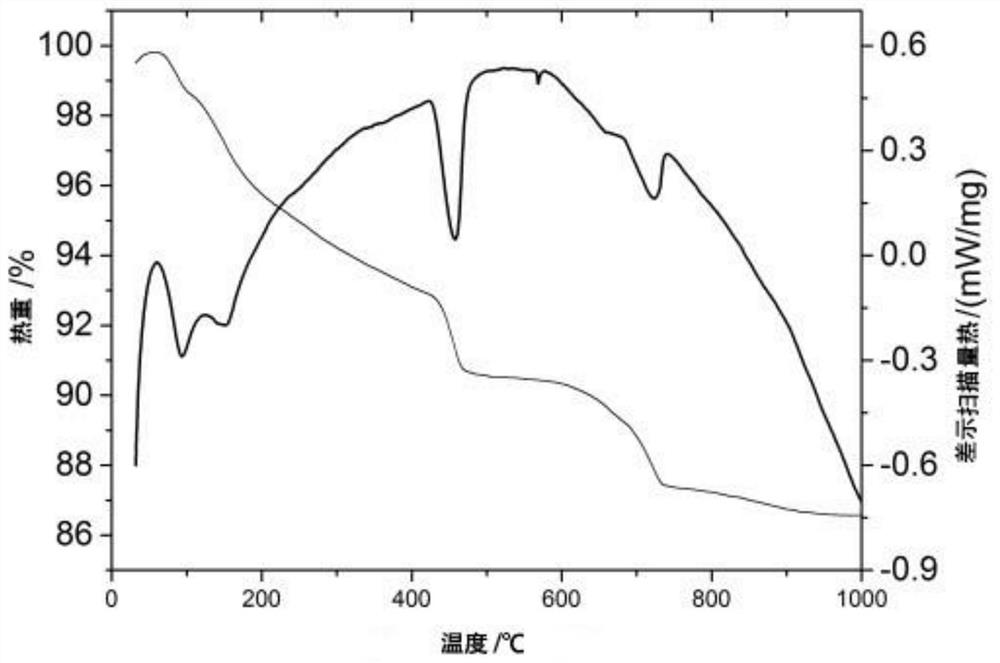

Image

Examples

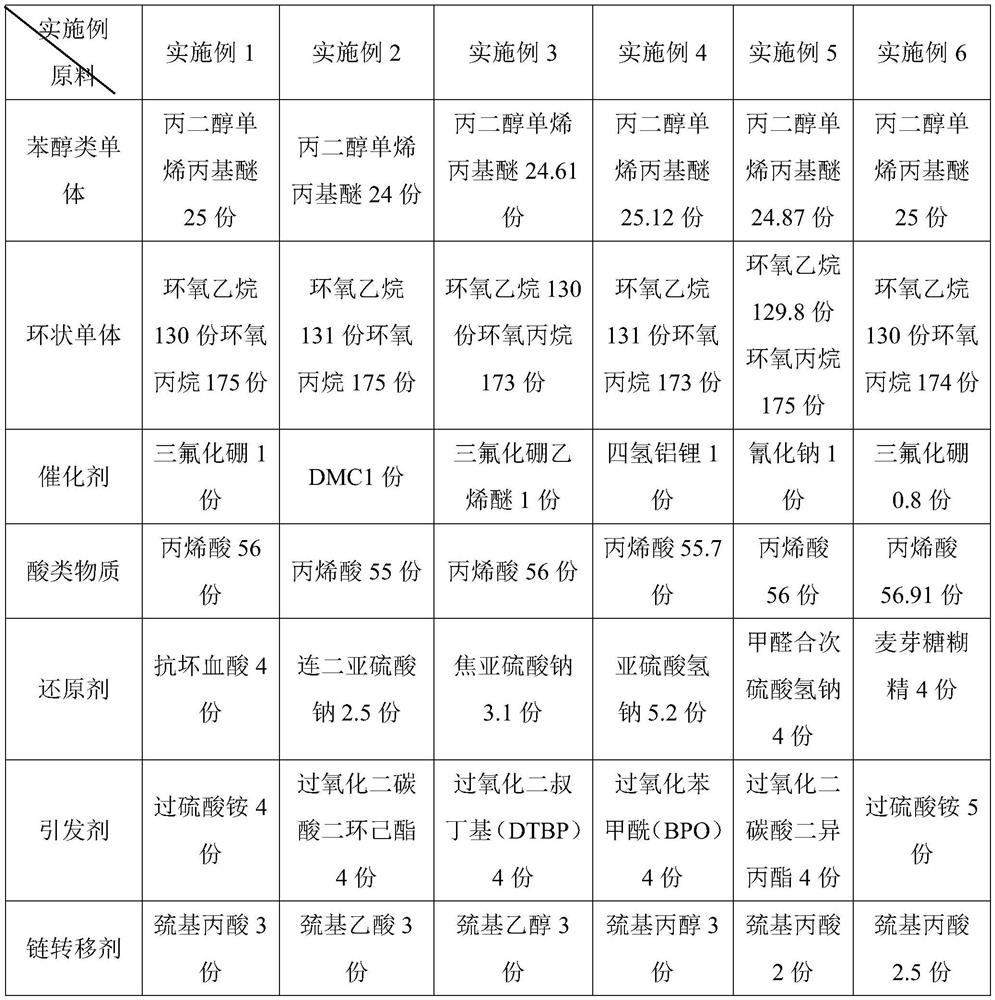

Embodiment 1

[0041] The total mass fraction of raw materials for preparing the low slump type water reducing agent is 1000 parts, each mass fraction is 1 g in this embodiment, and the mass fractions of each raw material are as follows:

[0042] Polyether alcohol head: 25 parts of propylene glycol monoallyl ether;

[0043] Cyclic monomers: 305 parts of ethylene oxide and propylene oxide, including 130 parts of ethylene oxide and 175 parts of propylene oxide;

[0044] Catalyst: 1 part of boron trifluoride;

[0045] Acid substances: 56 parts of acrylic acid;

[0046] Reducing agent: 4 parts of ascorbic acid;

[0047] Initiator: 4 parts of ammonium persulfate;

[0048] Chain transfer agent: 3 parts of mercaptopropionic acid;

[0049] Neutralizer: 7 parts of sodium carbonate;

[0050] The rest is deionized water.

[0051] The specific operation steps of the preparation method are as follows:

[0052] Step 1: Add 25 parts of propylene glycol monoallyl ether and 1 part of boron trifluoride t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com