Extraction process of dietary fibers in sweet potatoes

A technology of dietary fiber and extraction process, which is applied in the field of extraction process of dietary fiber in sweet potato, can solve problems such as low extraction rate, complicated extraction process operation, product pollution, etc., achieve sufficient fermentation process, increase economic value, and complete enzymatic hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

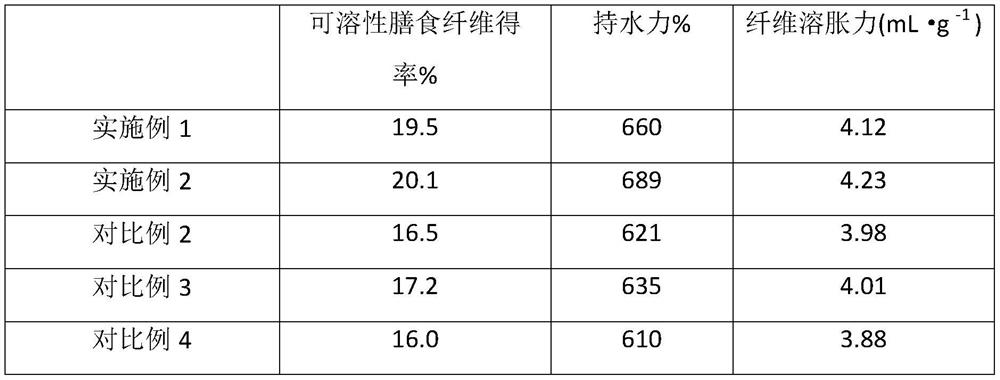

Embodiment 1

[0026] A kind of extraction process of dietary fiber in sweet potato, comprises the following steps:

[0027] 1) Wash and peel fresh sweet potatoes, slice them, wash them in clean water for several times, dry them in an oven at 60°C for 48 hours, and pulverize them in an ultrafine pulverizer to obtain sweet potato residues;

[0028] 2) According to the solid-liquid ratio of 1:3, mix the sweet potato residue and 10% sodium carbonate aqueous solution evenly, and hydrolyze at 50°C for 60 minutes, cool and filter;

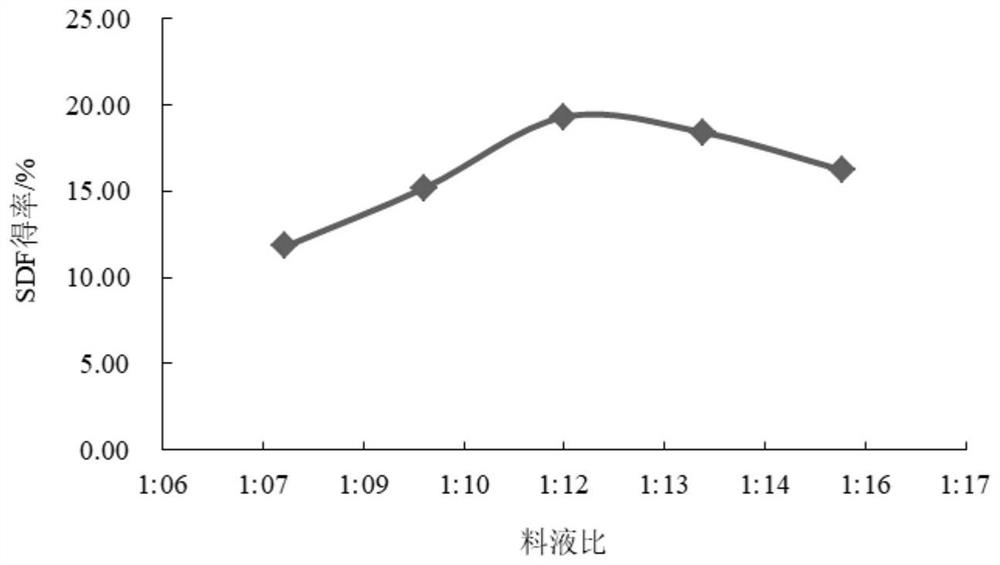

[0029] 3) Add sterile water to the material obtained in step (2) according to the material-to-liquid ratio of 1:12, sterilize under high-pressure steam at 120°C for 1 hour, and then add a starter culture agent in an amount of 0.3% of the total weight of the material, and then inoculate the inoculated Place the sweet potato material at 25°C for fermentation and cultivation for 24 hours to obtain a sweet potato dregs fermentation liquid; then add amylase and papain to fu...

Embodiment 2

[0038] A kind of extraction process of dietary fiber in sweet potato, comprises the following steps:

[0039] 1) Wash and peel fresh sweet potatoes, slice them, wash them in clean water for several times, dry them in an oven at 60°C for 48 hours, and pulverize them in an ultrafine pulverizer to obtain sweet potato residues;

[0040] 2) According to the solid-liquid ratio of 1:3, mix the sweet potato residue and 10% sodium carbonate aqueous solution evenly, and hydrolyze at 50°C for 90 minutes, cool and filter;

[0041] 3) Add sterile water to the material obtained in step (2) according to the material-to-liquid ratio of 1:12, sterilize under high-pressure steam at 130°C for 1 hour, and then add a starter culture agent in an amount of 0.5% of the total weight of the material, and then inoculate the inoculated The sweet potato material was placed at 28°C for fermentation and cultivation for 36 hours to obtain a sweet potato dregs fermentation liquid; then amylase and papain were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com