Novel steel pipe concrete column combined joint and construction method thereof

A technology of concrete-filled steel tubular columns and combined nodes, which is applied in the direction of construction and building structure, can solve the problems of difficult construction, great influence of human operation technology on construction quality and appearance, etc., and achieves convenient production process and installation process. The effect of reducing the difficulty of welding operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

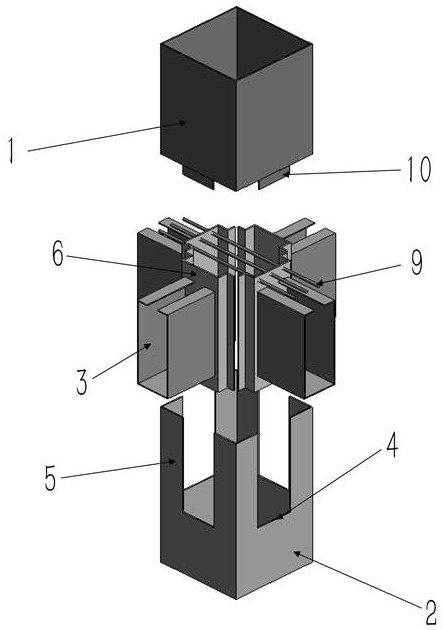

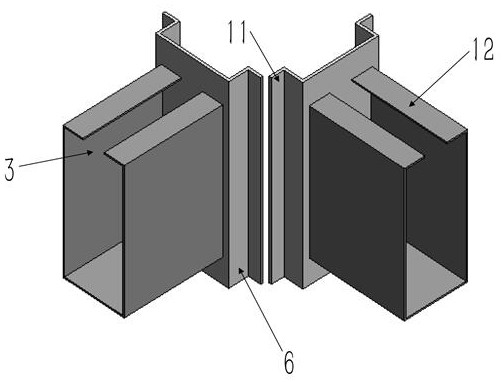

[0028] A new composite joint of concrete filled steel tube columns, see figure 1 , including vertically arranged upper steel pipe columns 1 and lower steel pipe columns 2, and a plurality of U-shaped steel beams 3, the upper edges of the two side walls of the steel beams are respectively bent and extended to form an upper flange 12, A slot 4 is provided on the side wall of the lower steel pipe column, and the slot extends downward from the upper end of the lower steel pipe column, and a connecting end 5 is formed on both sides thereof, and one end of the steel beam passes through the slot and then extends into the lower In the steel pipe column, it is connected with a vertical end plate 6, and the two sides of the end plate are fixedly connected with the connection ends on both sides of the slot; the upper steel pipe column is located above the lower st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com