Manganese complexes as x-ray scintillator materials and their applications in the preparation of flexible x-ray scintillator films

A scintillator material, manganese complex technology, applied in the directions of luminescent materials, polycrystalline material growth, crystal growth, etc., can solve the problems of increased self-absorption, low Stokes shift, etc., to reduce the preparation cost and stability. The effect of good and excellent photoluminescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

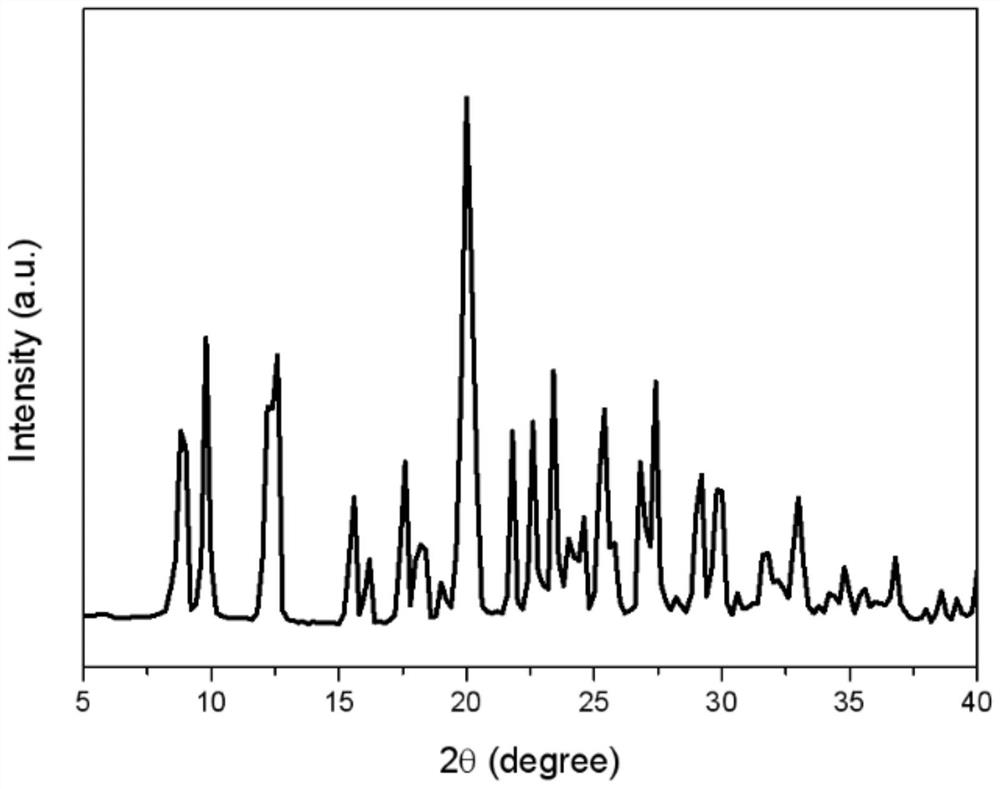

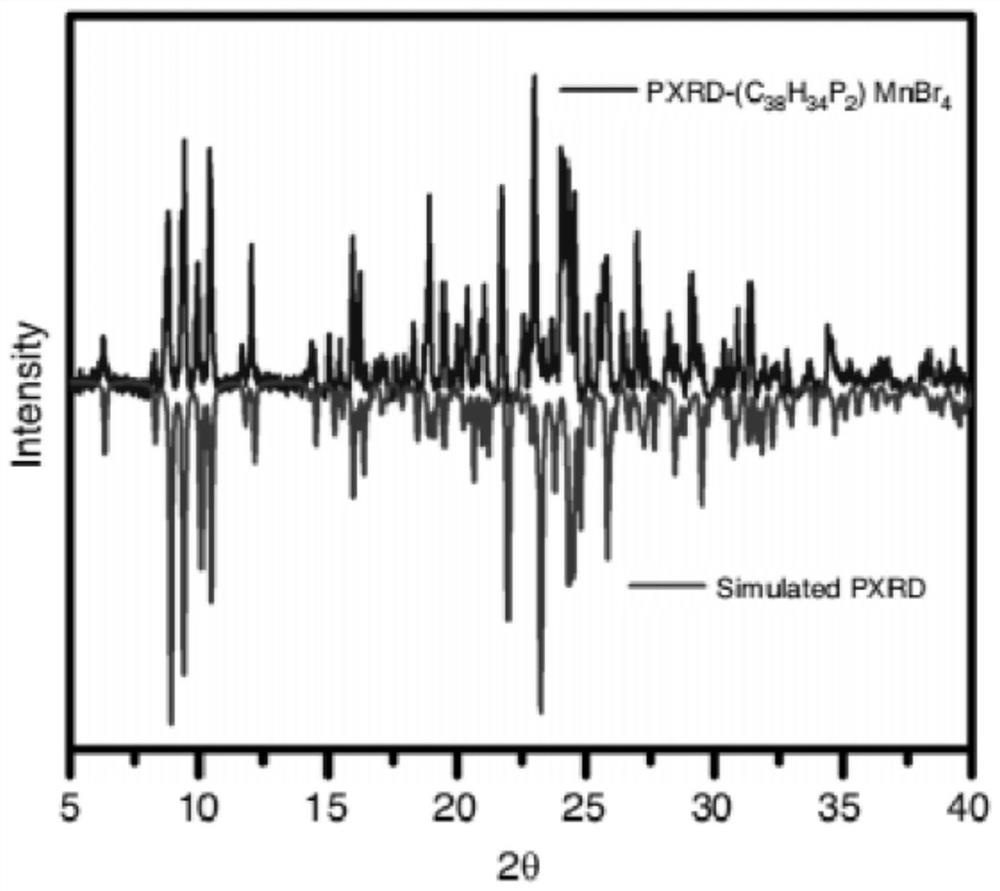

Image

Examples

Embodiment 1

[0044] Weigh manganese bromide (0.4295g, 2mmol) and tetraphenylphosphine bromide (C 24 H 20 BrP, 1.424 g, 4 mmol) in a molar ratio of 1:2, and the drug was dissolved in 10 mL of dichloromethane with stirring at room temperature. After the drug is completely dissolved, use a syringe to filter the mixed solution to remove impurities and undissolved particles. The filtered solution was placed openly in a container with 60 mL of anhydrous ether, left standing for three days, until the solvent was all volatilized completely to obtain (C 24 H 20 P) 2 [MnBr 4 ] Green manganese complex crystals. Yield 90.15%. preparation process such as figure 1 shown. The structure is as follows:

[0045]

Embodiment 2

[0047] The manganese complex crystal obtained in Example 1 was ground into powder with a mortar, and the powder with a particle size of 30 μm was sieved with a 30 μm aperture sieve for collection. The powder is uniformly stirred and mixed with PDMS at 20% by mass (monomer:curing agent=10:1) to obtain a mixed precursor. Centrifuge the mixed precursor at 500 r / min for 5 min to deposit larger particles into the lower layer, take the upper layer of the precursor and pour it into a 5cm×8cm rectangular template, place it and cure it at 80°C for 4 hours to obtain a thickness of 1-2mm. flexible scintillator films.

Embodiment 3

[0049] The preparation method is basically the same as that in Example 2, except that the crystal powder is uniformly stirred and mixed with PDMS at 10% by mass (monomer:curing agent=10:1) to prepare the flexible scintillator film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com