Method for extracting and separating trifluoroethanol and water azeotrope by using porous ionic liquid

A technology of ionic liquid and trifluoroethanol, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve problems such as high membrane cost, low reuse rate, and impact on human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment relates to a group of extraction agents used for extracting and separating trifluoroethanol and water, and its components are as follows:

[0027] porous ionic liquid Example 1.1 Porous Ionic Liquid Formed by Combining 1-Butyl-3-Methylimidazolium Bistrifluoromethanesulfonimide and ZIF-8 Example 1.2 Porous Ionic Liquid Formed by Combining 1-Hexyl-3-Methylimidazolium Bistrifluoromethanesulfonimide and ZIF-8 Example 1.3 Porous ionic liquid formed by combining n-ethylpyridine bistrifluoromethanesulfonimide with ZIF-8 Example 1.4 Porous ionic liquid formed by combining n-butylpyridine bistrifluoromethanesulfonimide with ZIF-8

[0028] The above-mentioned imidazole or pyridine porous ionic liquid extractant is taken as an example in Example 1.4, and the following preparation method is adopted: pyridine and brominated n-butane are reacted in an absolute ethanol solvent with a molar ratio of 1:1 to generate bromide ionic ...

Embodiment 2

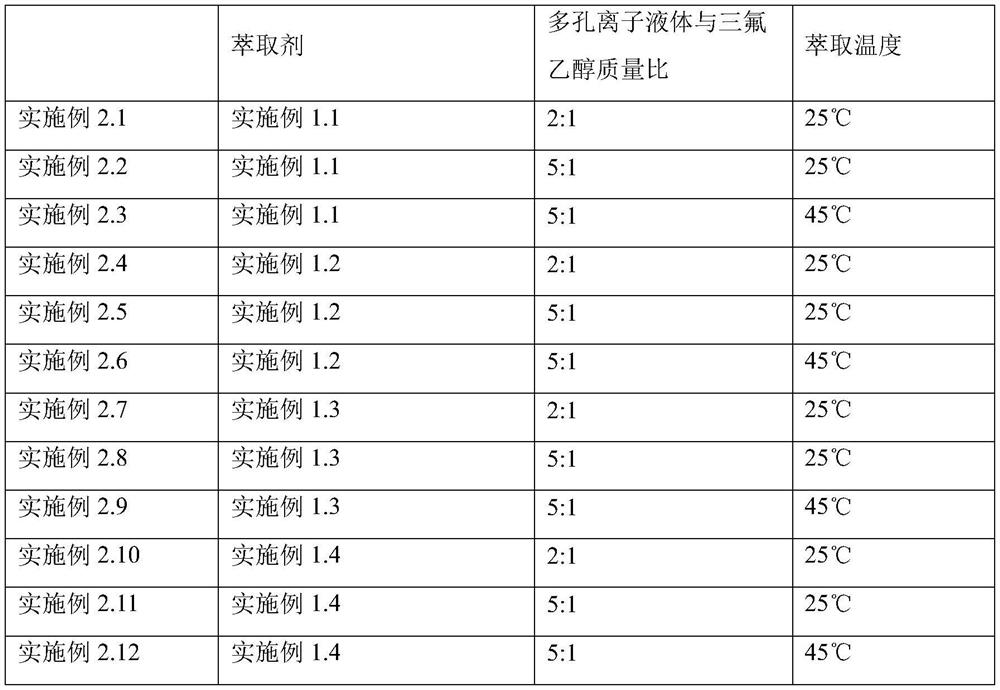

[0032] In the method for extracting and separating trifluoroethanol and water in this embodiment, the extraction conditions are limited as shown in the table below.

[0033]

Embodiment 3

[0035] The method for extracting trifluoroethanol and water with the porous ionic liquid of this embodiment, the extraction conditions and experimental results are shown in the table below.

[0036] Extracting agent Stirring time min Standing time min Extraction efficiency% Example 3.1 Example 2.1 30 30 85.4 Example 3.2 Example 2.2 60 60 88.9 Example 3.3 Example 2.3 120 120 89.3 Example 3.4 Example 2.4 60 60 87.8 Example 3.5 Example 2.5 60 60 90.6 Example 3.6 Example 2.6 120 120 91.8 Example 3.7 Example 2.7 60 60 88.2 Example 3.8 Example 2.8 60 60 92.3 Example 3.9 Example 2.9 120 120 93.8 Example 3.10 Example 2.10 60 60 90.1 Example 3.11 Example 2.11 60 60 94.8 Example 3.12 Example 2.12 120 120 96.9

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com