A near-infrared band broadband emission rare earth doped bismuthate optical fiber glass and its preparation method

A technology of rare earth doping and bismuth salts, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of narrow spectral amplification bandwidth in the near-infrared band, limited gain range, and the amplification range cannot cover optical signal transmission Issues such as the lowest loss zone and zero dispersion zone achieve the effects of excellent physical and chemical properties, simple preparation process, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention provides a near-infrared band broadband emission rare earth doped bismuth salt optical fiber glass, which comprises the following steps:

[0028] (1) According to molar percentage, take each raw material respectively: Bi of 75mol% 2 o 3 , 19mol% B 2 o 3 , 4.4 mol% Na 2 O, 0.3 mol% Er 2 o 3 , 1.0mol% Yb 2 o 3 , 0.3mol% Pr 6 o 11 , for standby; wherein, the mass percent purity of each raw material is required to be 99.99%.

[0029] (2) Fully grind and mix the raw materials weighed in step (1), pour them into a corundum crucible, and place them in a high-temperature furnace at 1050° C. for 1 hour to obtain a glass solution.

[0030] (3) Take out the corundum crucible containing the glass solution from the high-temperature furnace, and quench and form it on a pre-heated graphite mold to obtain a glass sheet; wherein, the temperature of the pre-heated graphite mold is 300°C.

[0031] (4) Put the graphite mold poured with glass solution into t...

Embodiment 2

[0034] The present invention provides a near-infrared band broadband emission rare earth doped bismuth salt optical fiber glass, which comprises the following steps:

[0035] (1) According to molar percentage, take each raw material respectively: Bi of 75mol% 2 o 3 , 19mol% B 2 o 3 , 4.5 mol% Na 2 O, 0.3 mol% Er 2 o 3 , 1.0mol% Yb 2 o 3 , 0.2mol% Pr 6 o 11 , for standby; wherein, the mass percent purity of each raw material is required to be 99.99%.

[0036] (2) Fully grind and mix the raw materials weighed in step (1), pour them into a corundum crucible, and place them in a high-temperature furnace at 1050° C. for 1 hour to obtain a glass solution.

[0037] (3) Take out the corundum crucible containing the glass solution from the high-temperature furnace, and quench and form it on a pre-heated graphite mold to obtain a glass sheet; wherein, the temperature of the pre-heated graphite mold is 300°C.

[0038] (4) Put the graphite mold poured with glass solution into t...

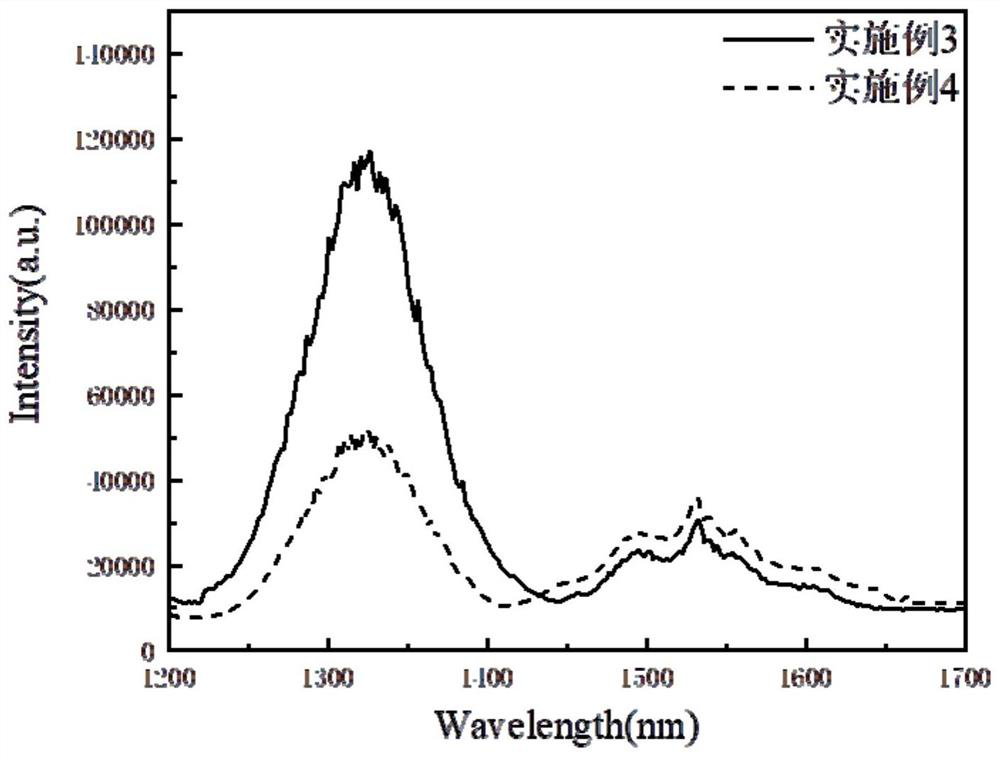

Embodiment 3

[0041] The present invention provides a near-infrared band broadband emission rare earth doped bismuth salt optical fiber glass, which comprises the following steps:

[0042] (1) According to mole percentage, take each raw material respectively: Bi of 74mol% 2 o 3 , 20mol% B 2 o 3 , 4mol% Na 2 O, 0.4 mol% Er 2 o 3 , 1.2mol% Yb 2 o 3 , 0.4mol% Pr 6 o 11 , for standby; wherein, the mass percent purity of each raw material is required to be 99.99%.

[0043] (2) Fully grind and mix the raw materials weighed in step (1), pour them into a corundum crucible, and place them in a high-temperature furnace at 1080°C for 1 hour to melt to obtain a glass solution.

[0044] (3) Take out the corundum crucible containing the glass solution from the high-temperature furnace, and quench and form it on a pre-heated graphite mold to obtain a glass sheet; wherein, the temperature of the pre-heated graphite mold is 300°C.

[0045] (4) Put the graphite mold poured with glass solution into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com