Diffuse reflector and manufacturing method thereof

A manufacturing method and technology of diffuse reflector, which can be applied to diffuse elements, instruments, optics, etc., can solve the problems of affecting measurement work efficiency, poor material stability, and difficult to store, and achieve good thermal stability and chemical stability, high Stable, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

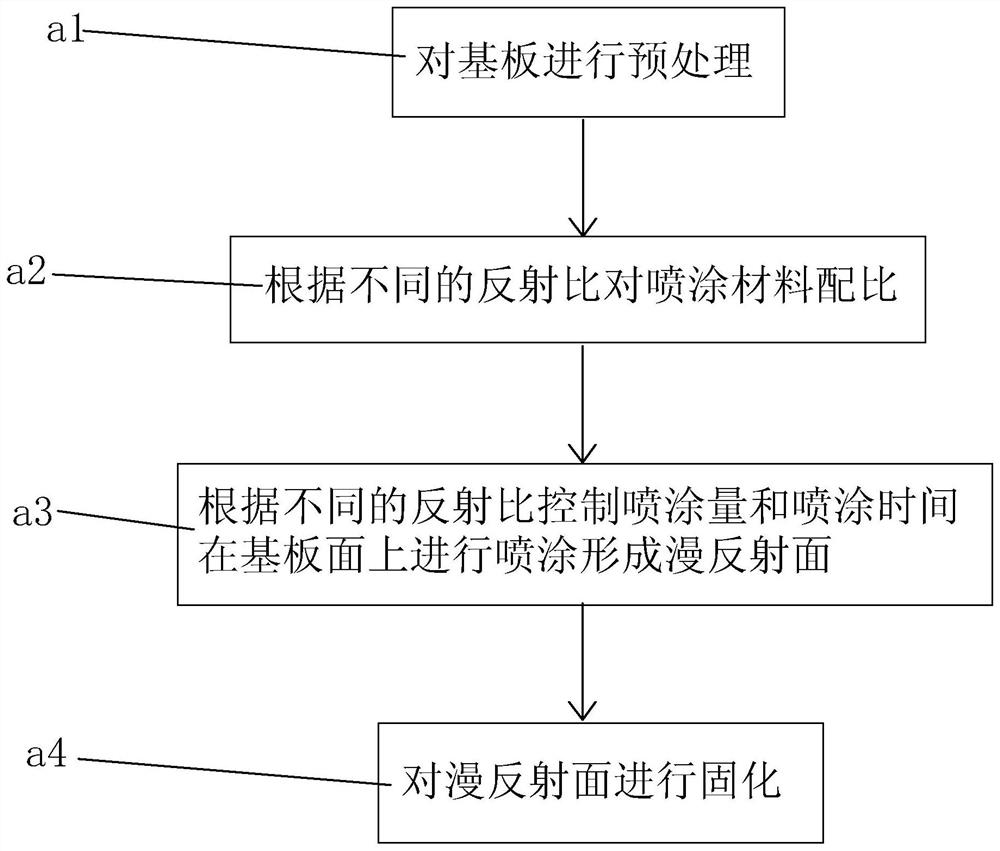

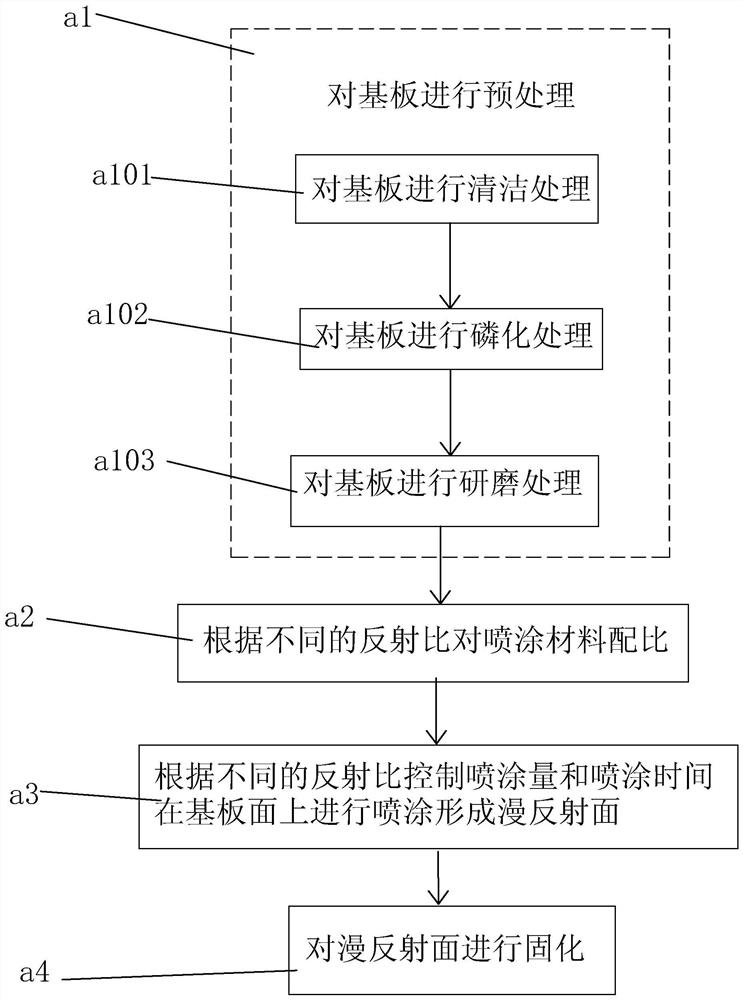

[0029] refer to figure 1 , a manufacturing method of a diffuse reflector, comprising the following steps:

[0030] Step a1, pretreating the substrate;

[0031] Step a2, according to different reflectance ratio spraying material proportioning;

[0032] Step a3, controlling the amount of spraying and spraying time according to different reflectances to spray on the substrate surface to form a diffuse reflection surface;

[0033] Step a4, curing the diffuse reflection surface.

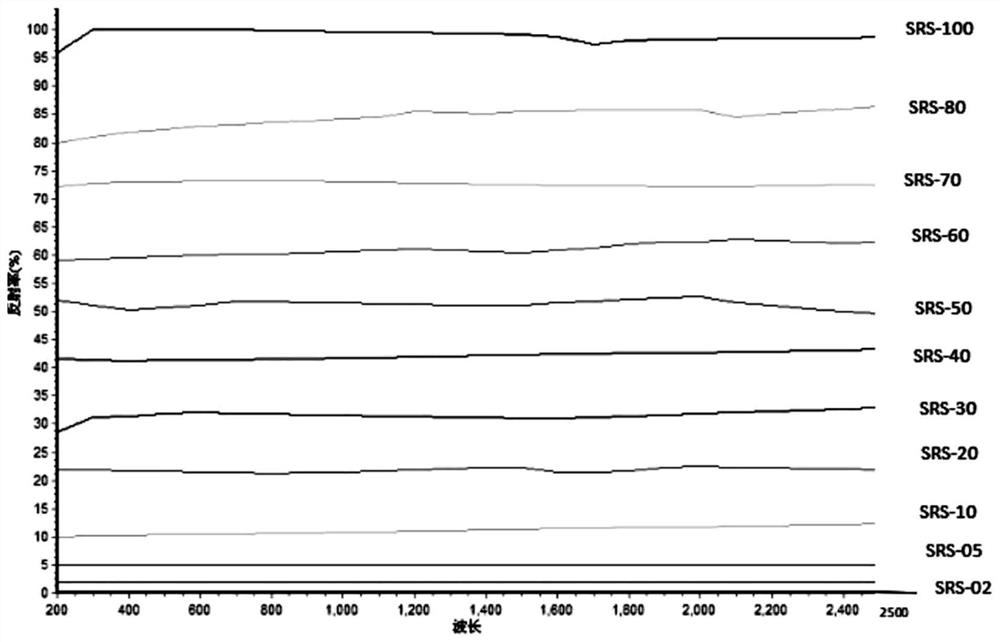

[0034] refer to image 3 , image 3 It is a graph of the relationship between wavelength and reflectance of spraying materials with different ratios; diffuse reflectors with different reflectances are used for different functional purposes, and the ratios are made according to actual requirements; different ratios of sprayed materials will affect the reflection of the diffuse reflection layer Ratio, the specific available reflectance is 2% to 99%. At the same time, due to the different proportions o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com