Intelligent aerogel in-situ composite system with shape memory performance and preparation method thereof

An aerogel original and aerogel technology, which is applied in the field of intelligent aerogel in-situ composite system and its controllable preparation, can solve the problem that fillers such as nanomaterials are difficult to disperse uniformly, nanoparticle dispersion is uneven, and performance controllability is poor. and other problems, to achieve good industrial application potential, strong designability, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

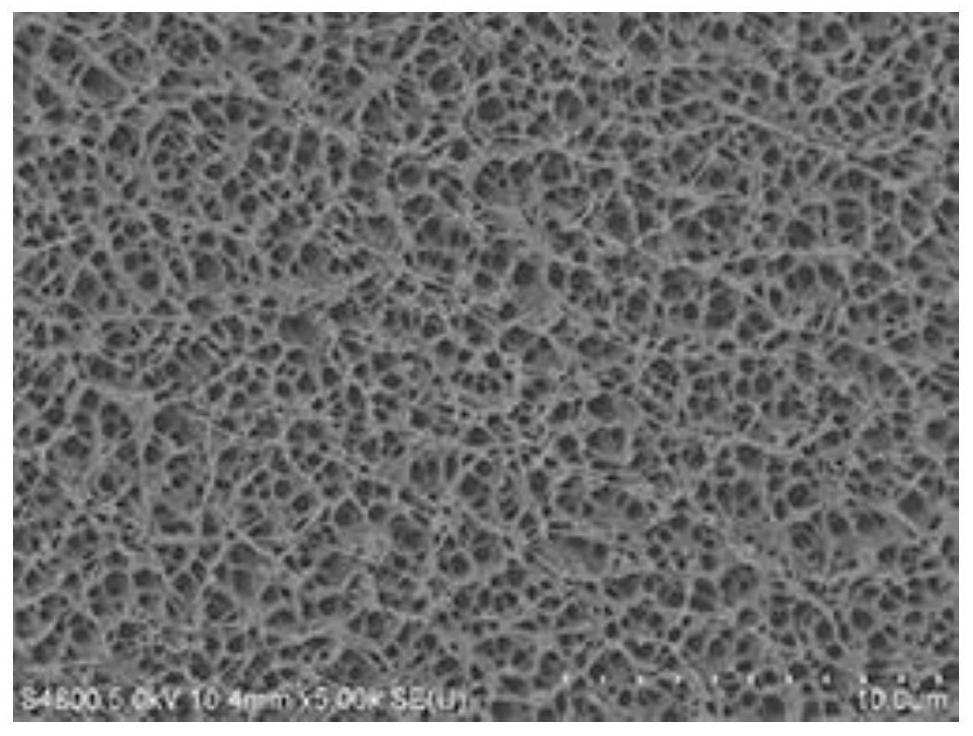

[0025] The method for preparing the intelligent airgel in-situ composite system provided by the present invention can design and prepare the microstructure and properties at the nanometer scale according to application requirements.

[0026] The intelligent airgel in-situ composite system can be used in the following fields.

[0027] (1) By rationally designing the nanoparticle morphology, porosity, pore structure, and surface functional group types and quantities in the smart airgel in-situ composite system, it can be used for environmental energy catalysis, energy storage, marine resource development and utilization, medicine, Artificial enzymes, porous electrodes, intelligent adsorption and detection, etc.

[0028] (2) Utilize vacuum freeze-drying-controlled carbonization method to regulate the micro- and macro-structure of the smart airgel in-situ composite system, which can be used as a lightweight smart structural material for construction, machinery, smart protection, f...

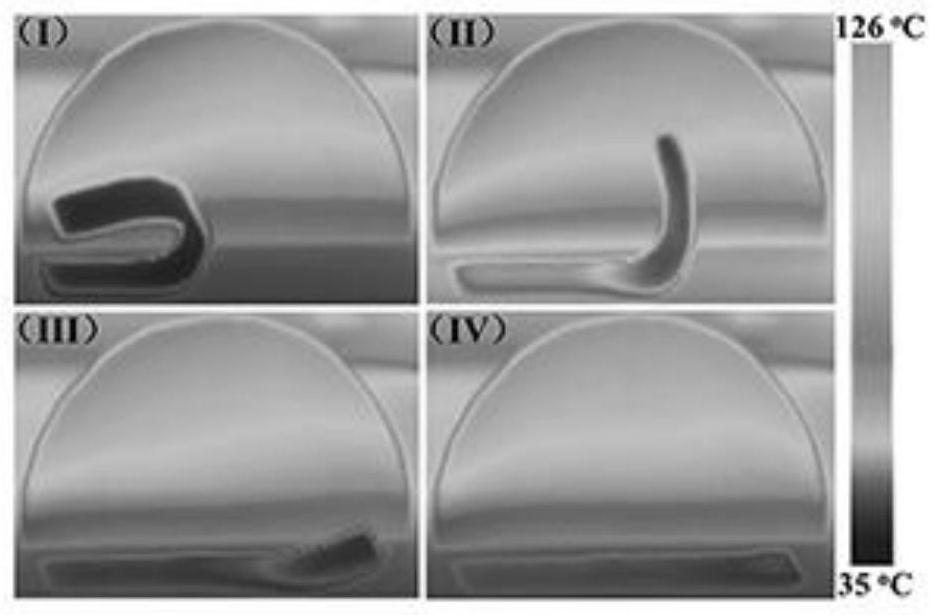

Embodiment 1

[0032] At room temperature, add 6.0 g polyvinyl alcohol into 100.0 ml deionized water and stir for 2.0 h. After fully swelling, slowly heat the solution to 100.0 ml while stirring. o C was stirred at constant temperature for 3.0 h to fully dissolve until the whole solution was free of particles, clear and uniform, and then cooled to room temperature to obtain a polyvinyl alcohol solution. The pH value of the polyvinyl alcohol solution was adjusted to 3.5 with hydrochloric acid, and after stirring for 1.0 h, 5.0 ml of glutaraldehyde was added while stirring, and the stirring was continued for 2.0 h to obtain a prepolymer solution. After pouring the pre-polymerization solution into the mold, carry out vacuum static degassing treatment for 3.0 h, at -25.0 o Under the condition of C, pre-freeze for 1.0 h, then at -60.0 o Under the condition of C, it was pre-frozen for 2.0 h, vacuum freeze-dried, and then released from the mold to obtain the aerogel. Put the airgel at 90.0 o Und...

Embodiment 2

[0034] At room temperature, add 6.0 g polyvinyl alcohol into 100.0 ml deionized water and stir for 2.0 h. After fully swelling, slowly heat the solution to 100.0 ml while stirring. o C was stirred at constant temperature for 3.0 h to fully dissolve until the solution was free of particles, clear and uniform, and then cooled to room temperature to obtain a polyvinyl alcohol solution. The pH value of the polyvinyl alcohol solution was adjusted to 3.5 with hydrochloric acid, and after stirring for 1.0 h, 5.0 ml of glutaraldehyde was added while stirring, and the stirring was continued for 2.0 h to obtain a prepolymer solution. After pouring the pre-polymerization solution into the mold, carry out vacuum static degassing treatment for 3.0 h, at -25.0 o Under the condition of C, pre-freeze for 1.0 h, then at -60.0 o Under the condition of C, it was pre-frozen for 2.0 h, vacuum freeze-dried, and then released from the mold to obtain the aerogel. Put the airgel at 90.0 oUnder the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com