Plastic uptake mold flow rate adjusting device

A technology for adjusting devices and blister molds, which is applied to household components, household appliances, and other household appliances. It can solve the problems of inconvenient adjustment and affecting processing efficiency, and achieve the effect of preventing uneven moving distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

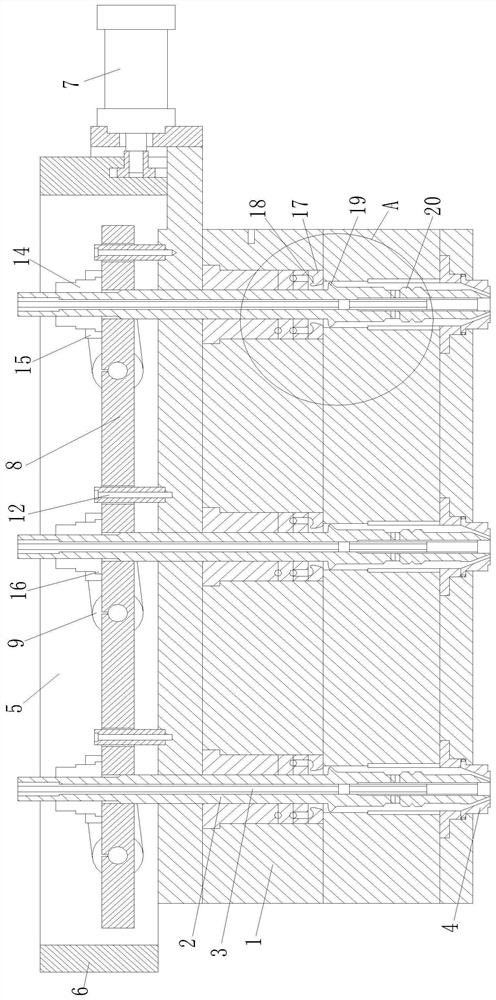

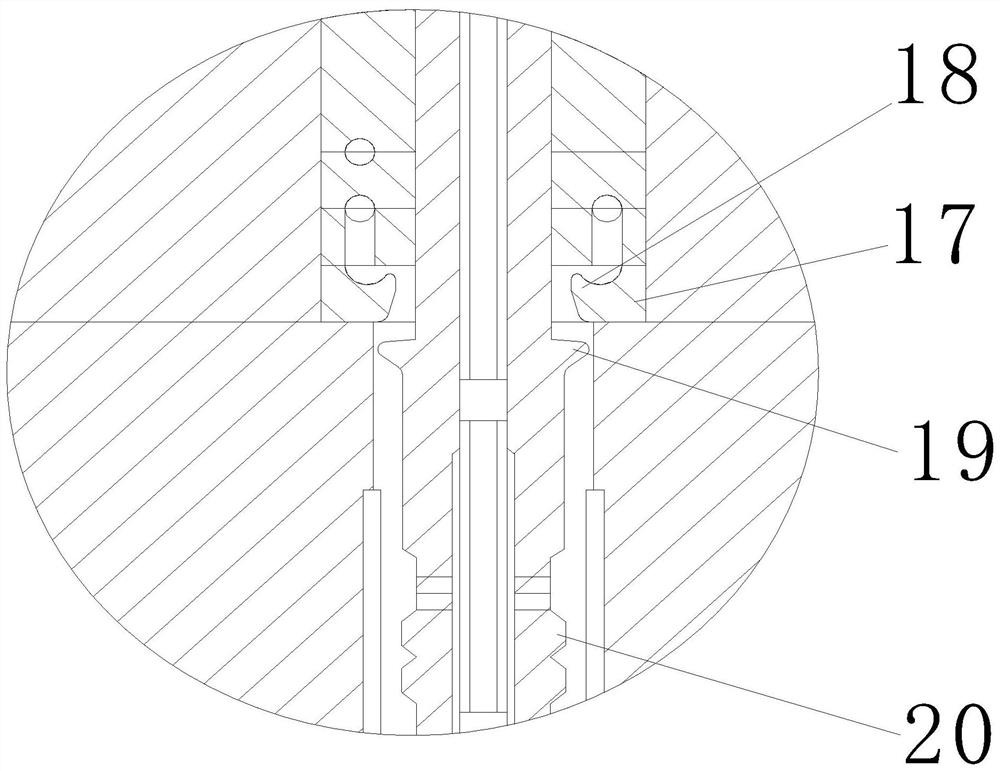

[0025] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

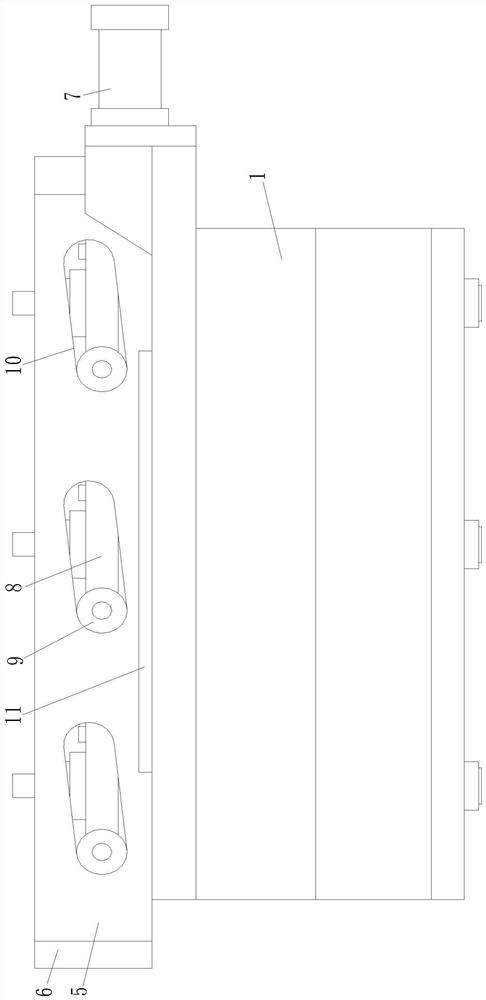

[0026] As shown in the figure, the present invention is a device for adjusting the flow rate of a plastic suction mold, which includes a main body 1 of a tube embryo suction mold, and a plurality of hollow tubular main mandrels 2 are arranged inside the main body 1 of the tube blank suction mold. The main mandrel 2 is slidingly connected with the main body 1 of the tube blank plastic mold, and the main mandrel 2 is provided with a plastic tube 3, which is sleeved in the main mandrel 2 and shared with the main mandrel 2. Shaft setting; the lower end of the main mandrel 2 protrudes from the lower end surface of the tube embryo suction mold main body 1, and the lower end of the tube embryo suction mold main body 1 is fixedly connected with an internal hollow forming die 4, and the main mandrel 2 The lower end is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com