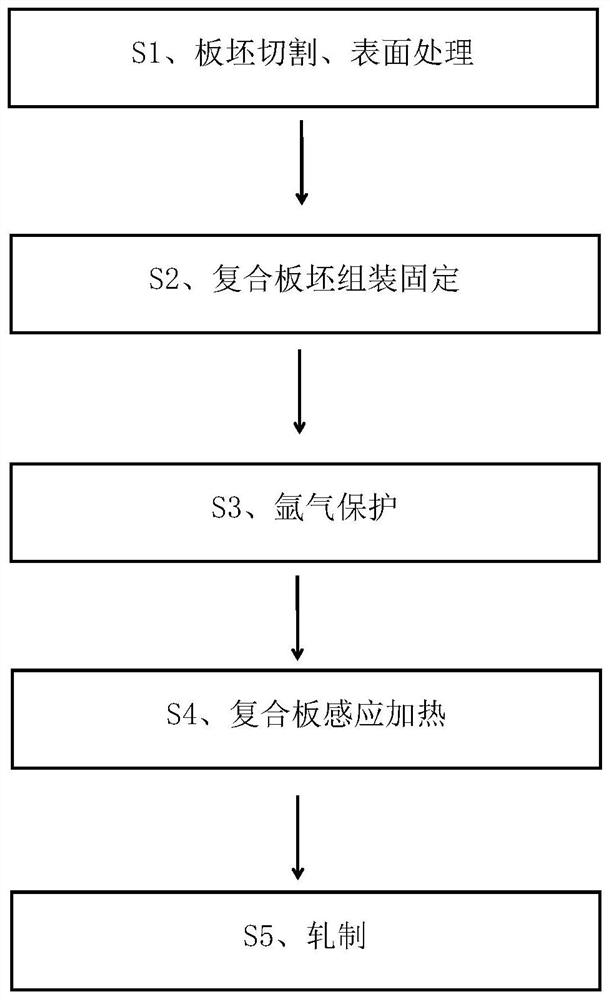

Method for preparing titanium-steel composite plate by adding pure iron interlayer through electromagnetic induction heating rolling

An electromagnetic induction heating, induction heating technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as difficulty in compounding, reducing the bonding strength of clad plates, affecting the bond strength of clad plates, etc., to achieve a firm metallurgical bond , reduce the critical deformation rate, easy to fit the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

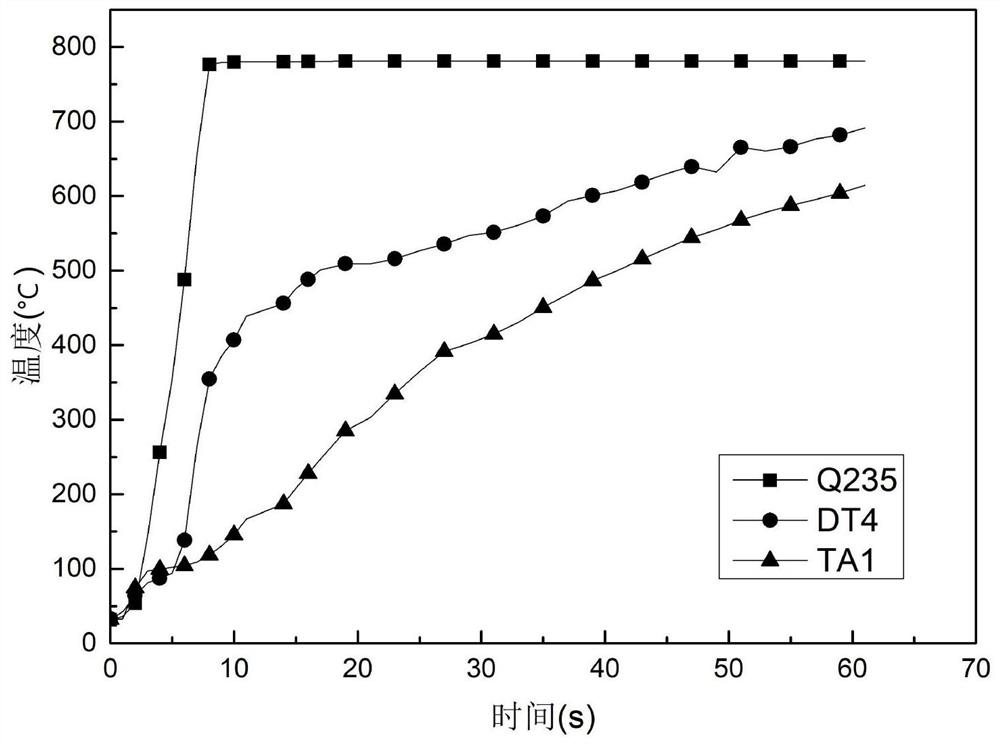

[0041](1) TA1 titanium plate, Q235 steel plate and DT4 pure iron plate, Q235 steel plate and DT4, respectively, respectively, 2 mm, 5 mm, and 1 mm, and then sandwich the three sheets, respectively, the thickness, respectively. The angle, then remove the oil and oxide layer of the pure iron plate and the titanium plate to be composite surface with a flat plate grinding machine having a particle diameter of 150 μm, and remove the oxide layer of the steel plate composite surface with a steel wire having a diameter of 0.3 mm. The slab composite surface is cleaned according to the cleaning of alcohol-acetone-alcohol, and finally seals the spare after drying with a hair dryer;

[0042](2) The above slabs is stacked in the order of the steel sheet, the pure iron plate, and the titanium plate, and then riveted with stainless steel rivets after drilling.

[0043](3) Displace the slab into the induction heating furnace of a length of 210 mm wide, coincide with the coil axis, the outer surface of th...

specific Embodiment 2

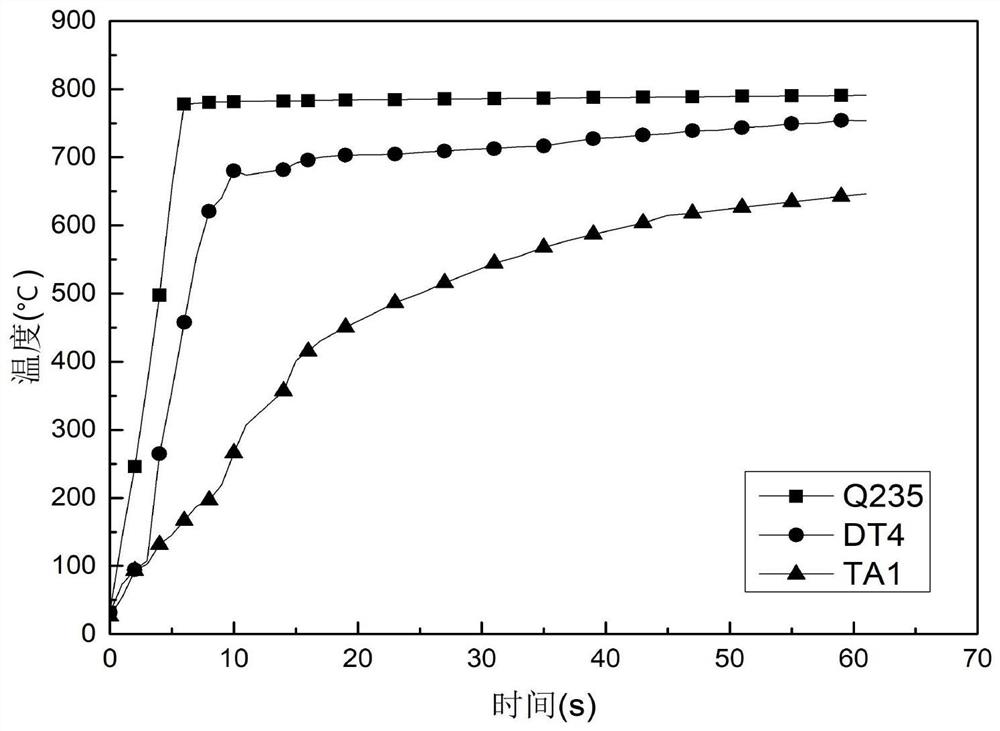

[0048](1) TA1 titanium plate, Q235 steel plate and DT4 pure iron plate, Q235 steel plate and DT4, respectively, respectively, respectively, and the thickness is 2.5 mm, 5 mm and 0.5 mm, and then the grinding wheel is applied to a certain inclination on the three plates, respectively. chamfer, followed by grinding with a particle size of 150μm tablet polishing pad removing oil and pure iron and titanium composite oxide layer of the surface to be, 0.3mm diameter steel wire brush to remove the surface oxide layer composite sheet, polished The post-slab composite surface is cleaned with degreasing cotton according to the cleaning method of alcohol-acetone-alcohol, and finally the sealed storage is stored after drying;

[0049](2) The above slab is placed in sequentially in the order of titanium plate, pure iron plate, and steel plate, and then riveted with stainless steel rivets after drilling.

[0050](3) Displace the slab into the induction heating furnace of the length of 210 mm wide, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com