Contact piece and connector

A technology of contact parts and contact rings, applied in contact parts, welding/welding connections, connections, etc., can solve problems such as physical gaps, pollution from excessive usage, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

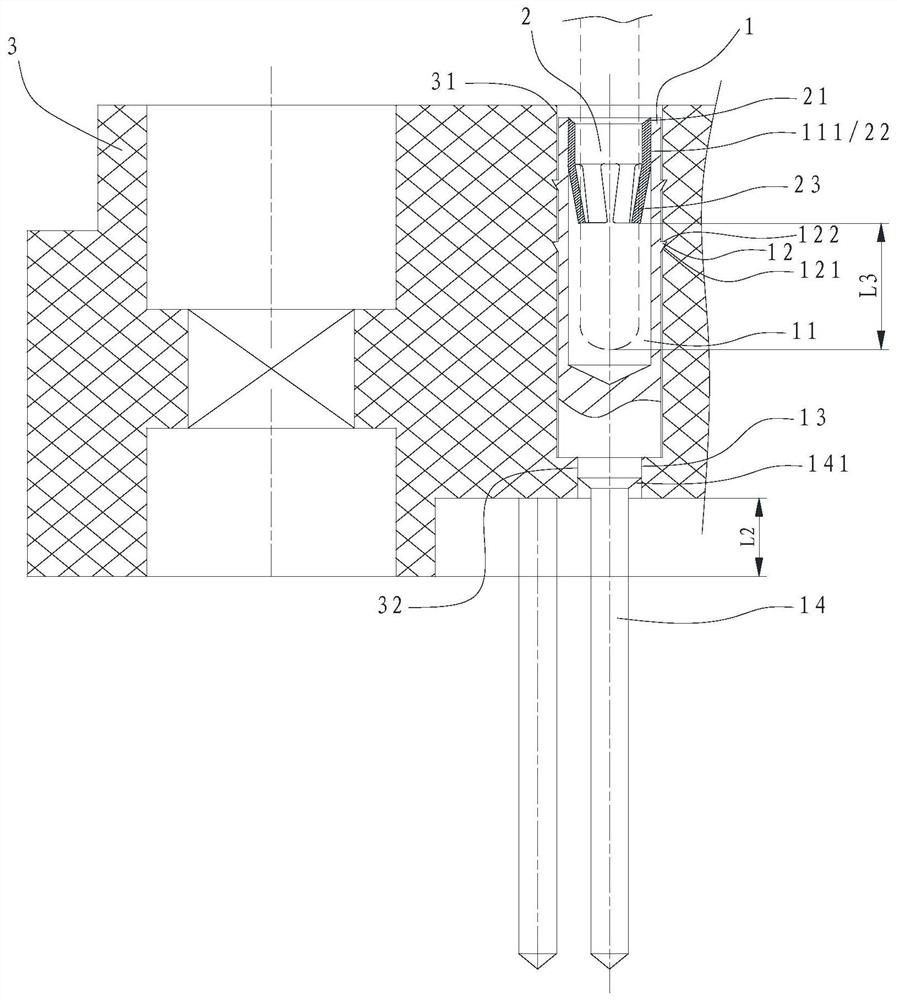

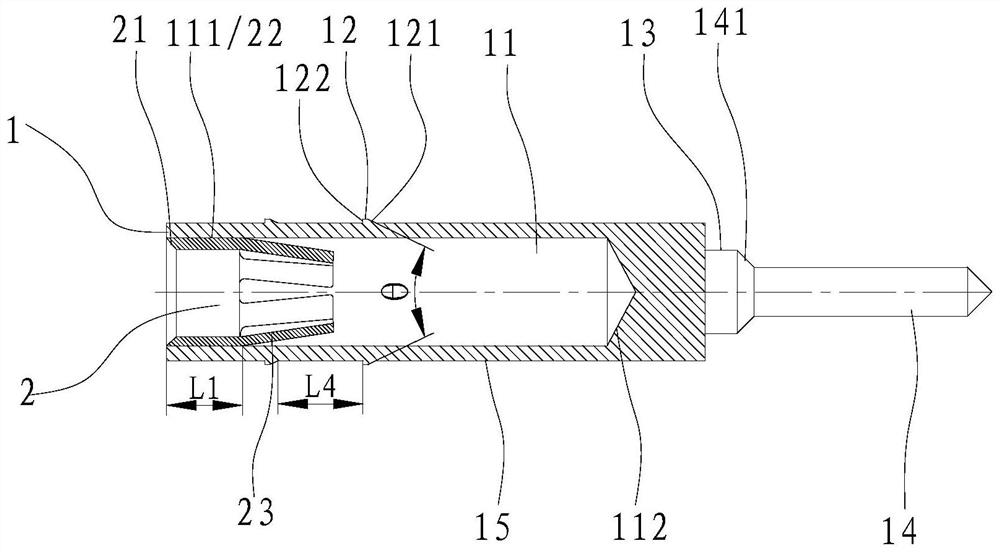

[0038] Such as figure 1 , figure 2As shown, a contact piece includes a body 1 and an elastic mechanism. The butt end of the body 1 is a socket of a standard diameter, and the socket is provided with a blind hole 11 for loading the elastic mechanism. The elastic mechanism is a spring claw 2, and Through the elastic interference fit of the outer circle 22 of the spring claw and the mouth 111 of the blind hole 11, the minimum interference fit of the circumference is 0.01mm, and the axial height L1 of the matching section is not less than 0.5mm, so as to ensure the outer circle of the spring claw 22 and the blind hole opening 111 to prevent the spring claw 2 from coming out under force when the connector is plugged and pulled out. The outer wall 15 of the body 1 is designed with double-circle struts 12 that are interference fit with the base 3, and the struts 12 form a complete and continuous whole around the outer wall 15, so that the two circles of struts are opposite to the o...

Embodiment 2

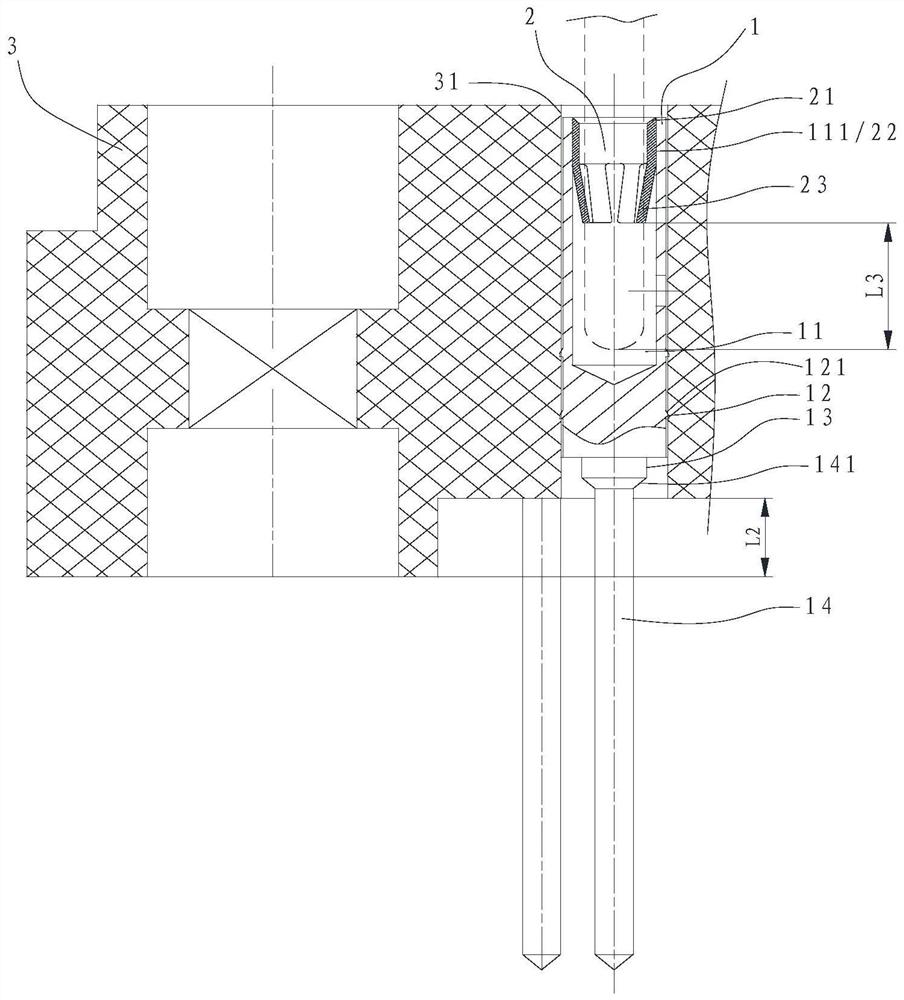

[0045] Such as image 3 , Figure 4 As shown, on the basis of the structure of Embodiment 1, the structure of the socket and the base 3 has the following changes:

[0046] A process hole 16 is added to the side wall of the bottom 112 of the blind hole 11, and the diameter of the process hole 16 cannot be less than φ0.3mm, so as to ensure the coating coverage and environmental resistance of the bottom 112 of the inner hole. At this time, the two circles of stabs 12 are located between the process hole 16 and the tail end of the insertion hole, and the tapered surface 121 of the stabs 12 is arranged on the side close to the butt end of the insertion hole. At this time, the inner hole 31 of the base 3 is a through-hole structure, and the socket needs to be punched from the rear end of the base 3 to the butt end.

[0047] The structure of this embodiment is preferentially applicable to structures in which the diameter of the blind hole 11 is less than 1 mm and the ratio of diame...

Embodiment 3

[0049] Such as Figure 5 , Figure 6 As shown, on the basis of the structure of Embodiment 1, the structure of the jack and the elastic mechanism have the following changes:

[0050] The blind hole 11 is provided with a process hole 16 near the hole bottom 112. The process hole 16 is located between two circles of struts 12. The elastic mechanism is a contact ring 4 with light insertion force and high vibration and impact resistance. The contact ring 4. It includes the punching 41 in the middle and the supporting parts 42 at both ends. The elastic force generated by the supporting part 42 is against the mouth 111 and the bottom 112 of the blind hole 11, wherein the supporting part 42 at the bottom 112 is close to the process hole 16 , still keep the confined space in a relatively sealed state, to achieve the effect of blocking the flow of organic solvents such as flux. The opening of the blind hole 11 is provided with a turning riveting structure 17 to improve the fixity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com