Soft package polymer lithium ion battery corner sealing process

A technology of lithium-ion batteries and polymers, which is applied to battery pack components, battery boxes/coats, secondary battery gas removal, etc., and can solve problems such as easy cracked corners, scrapped batteries, and soft batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

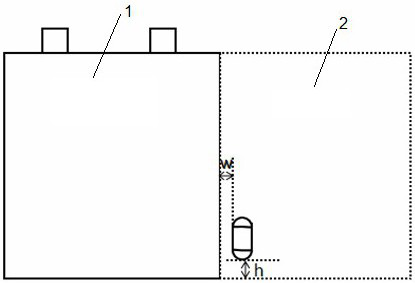

Embodiment 1

[0013] The battery cell model 9858102 adopts a hard sealing process, and the width of the top seal is 1.5~2.0mm. In pursuit of high energy density, the battery space design is compact, and the reserved space inside the top seal edge is only 0~0.4mm. A three-layer nylon-aluminum-plastic film is used for packaging. The thickness of the nylon layer on the outside of the nylon-aluminum-plastic film is 20±3μm, the thickness of the aluminum layer in the middle is 40±5μm, and the thickness of the inner PP layer is 40±5μm. The thickness of the adhesive between nylon layer or PP layer is 5~8μm. Corner sealing is performed with a "runway"-shaped corner sealing head. The length of the rectangular part of the head is 8mm, the width is 5mm, and the diameter of the two equal semicircles is also 5mm. The direction of the head is parallel to the height of the cell. The temperature of the upper and lower heads of the corner seal is 155°C, the pressure of the head is 0.25MPa, the sealing time i...

Embodiment 2

[0015] The battery cell model 9858102 adopts a hard sealing process, and the width of the top seal is 1.5~2.0mm. In pursuit of high energy density, the battery space design is compact, and the reserved space inside the top seal edge is only 0~0.4mm. A three-layer PET aluminum-plastic film is used for packaging. The thickness of the PET / nylon layer outside the PET aluminum-plastic film is 25±3μm, the thickness of the aluminum layer in the middle is 40±5μm, and the thickness of the PP layer inside is 50±5μm. The thickness of the adhesive between the aluminum layer and the PET / nylon layer or PP layer is 6-9 μm. Corner sealing is performed with a "runway"-shaped corner sealing head. The length of the rectangular part of the head is 8mm, the width is 5mm, and the diameter of the two equal semicircles is also 5mm. The direction of the head is parallel to the height of the cell. The temperature of the upper and lower heads of the corner seal is 160°C, the pressure of the head is 0.3M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com