Positive electrode material, and preparation method thereof and lithium ion battery

A technology of positive electrode materials and coating materials, applied in the field of battery materials, can solve problems such as requiring large distances, low energy density, and no room for improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

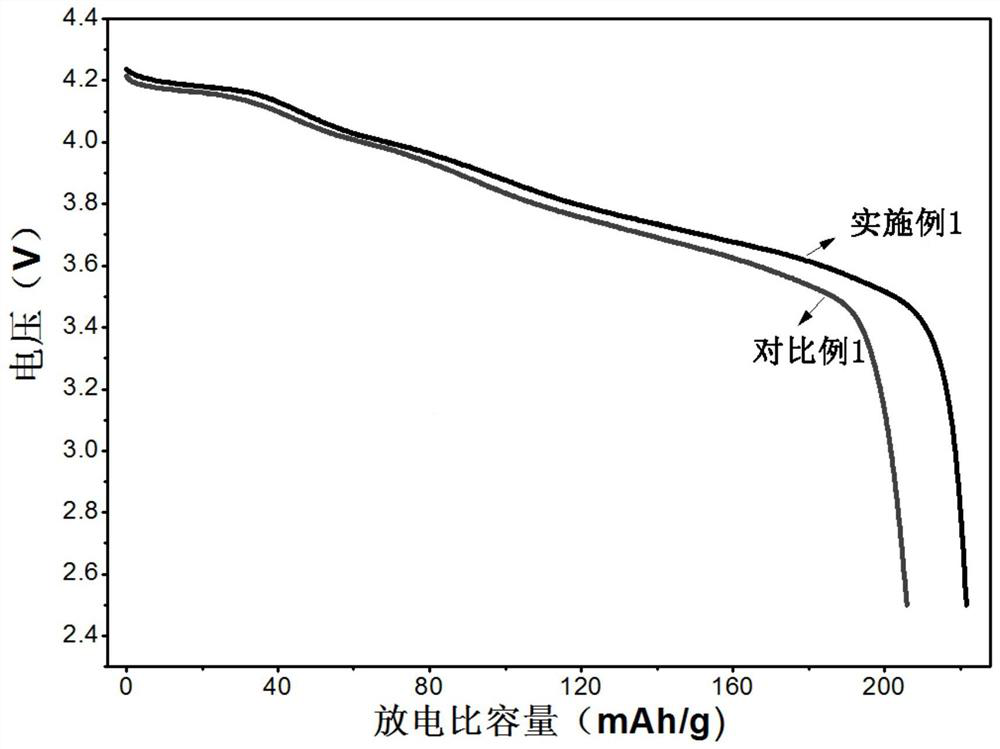

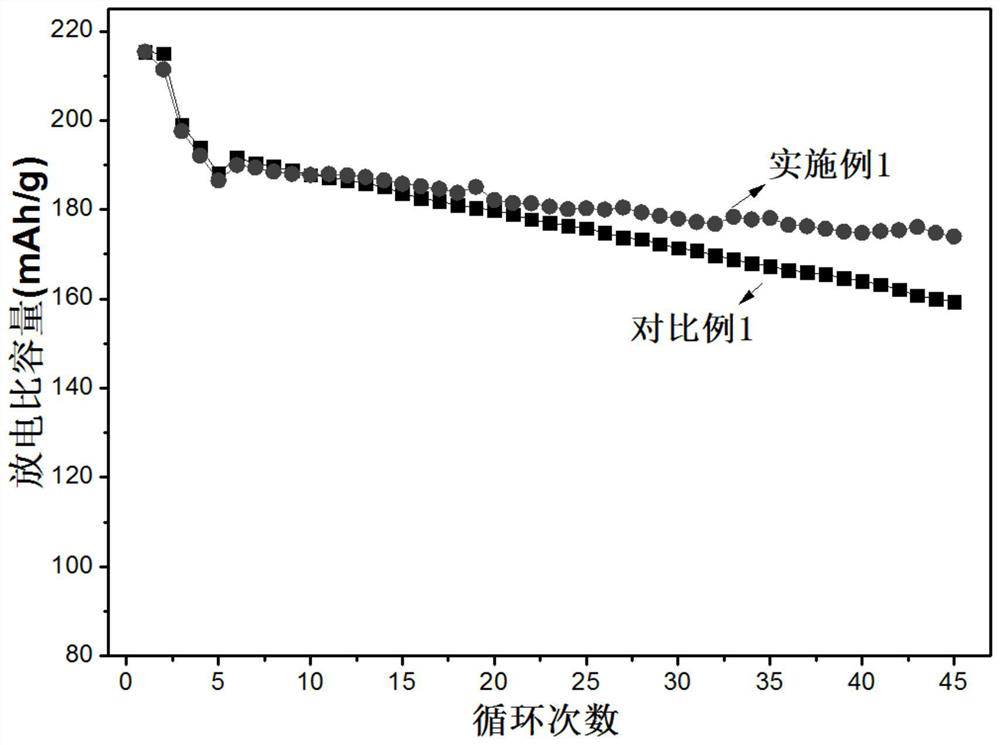

Examples

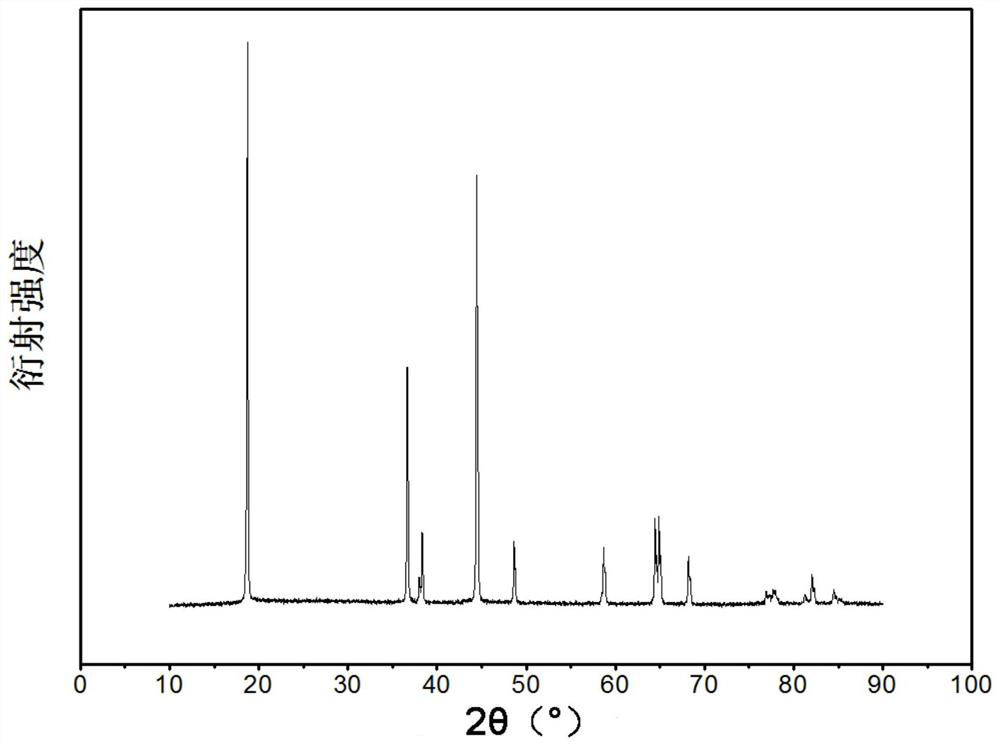

Embodiment 1

[0084] In this embodiment, the positive electrode material is prepared according to the following method:

[0085] (1) The commercial precursor (Ni 0.92 co 0.06 Al 0.02 (OH) 2 ) and LiOH are placed in a mixer according to accurate stoichiometric weighing and mixed for 40 minutes, and the water temperature is controlled at 30°C;

[0086] Wherein, the dehydration pretreatment is to pretreat the commercial precursor at 500° C. for 8 hours in an air atmosphere;

[0087] (2) After mixing evenly, take it out after heat treatment at 740°C for 15 hours, and pulverize to obtain LiNi 0.92 co 0.06 Al 0.02 o 2 The matrix material is crushed to control the particle size to the required target value, and the final matrix material is sealed and sealed for use;

[0088] (3) Al 2 o 3 , CoO and MnO 2 Dissolve in dilute nitric acid solution according to the element ratio of Al, Co and Mn of 1:1:1, dilute with deionized water, titrate with 50% ammonia water until the pH is about 7, sto...

Embodiment 2

[0094] In this embodiment, the positive electrode material is prepared according to the following method:

[0095] (1) Dehydrated and pretreated Li 0.98 Ni 0.93 co 0.02 Al 0.05 (OH) 2 Mix with LiOH in a mixer for 1 hour according to accurate stoichiometric weighing, and control the water temperature at 25°C;

[0096] Wherein, the dehydration pretreatment is to pretreat the commercial precursor at 400°C for 10h under an oxygen atmosphere;

[0097] (2) After mixing evenly, it was calcined at 700°C for 20 hours in an oxygen atmosphere, taken out, and crushed to obtain Li 0.98 Ni 0.93 co 0.02 Al 0.05 o 2 Base material, sealing and sealing the obtained base material for later use;

[0098] (3) AlCl 3 、Co(OH) 3 and MnO 2 Dissolve in dilute nitric acid solution according to the element ratio of Al, Co and Mn of 1:1:1, dilute with deionized water, titrate with 30% ammonia water until the pH is about 4, stop adding, let stand for 10h and then filter , the water temperatur...

Embodiment 3

[0103] In this embodiment, the positive electrode material is prepared according to the following method:

[0104] (1) Dehydrated and pretreated Li 1.03 Ni 0.88 co 0.08 mn 0.04 (OH) 2 Mix with LiOH in a mixer for 0.4h according to accurate stoichiometric weighing, and control the water temperature at 40°C;

[0105] Wherein, the dehydration pretreatment is to pretreat the commercial precursor at 600° C. for 5 hours under an oxygen atmosphere;

[0106] (2) After mixing evenly, calcined at 780°C for 6 hours in an oxygen atmosphere, took it out, and pulverized it to obtain Li 1.03 Ni 0.88 co 0.08 mn 0.04 o 2 Base material, sealing and sealing the obtained base material for later use;

[0107] (3) Al(OH) 3 , CoO and MnO 2 Dissolve in dilute nitric acid solution according to the element ratio of Al, Co and Mn of 1:1:1, dilute with deionized water, titrate with 50% ammonia water until the pH is about 11, stop adding, let stand for 20h and then filter , the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com